Flower Pot Garden - China Manufacturers, Suppliers, Factory

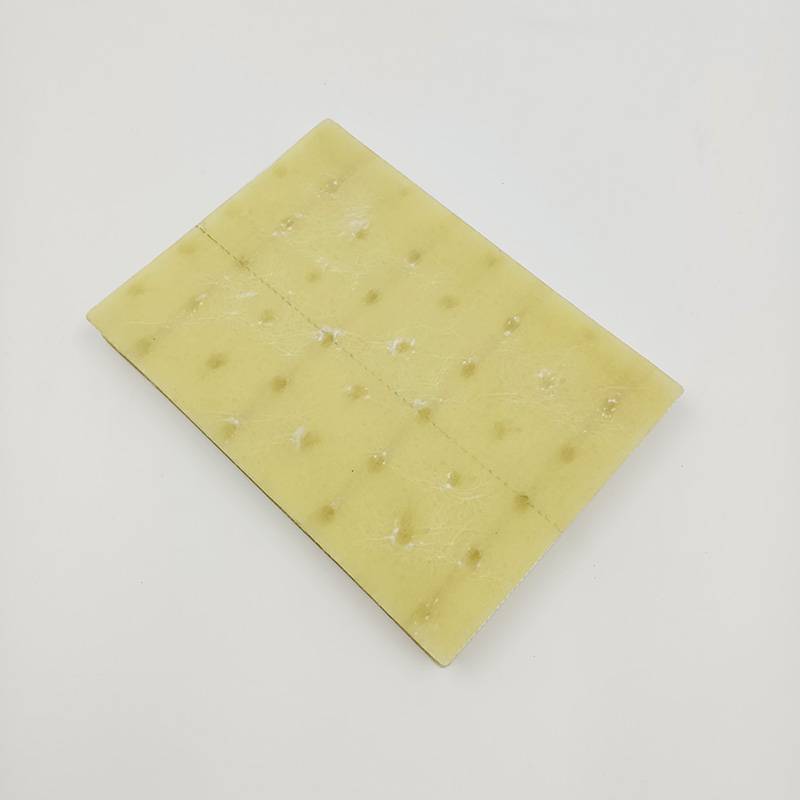

We always believe that one's character decides products' quality, the details decides products' quality ,with the REALISTIC,EFFICIENT AND INNOVATIVE team spirit for Flower Pot Garden, Fiberglass Mat With Good Stiffness, Chopped Basalt Fiber, Chopped Strands For Pp,Hollow Glass Beads. We are confident to make great achievements in the future. We are looking forward to becoming one of your most reliable suppliers. The product will supply to all over the world, such as Europe, America, Australia,Kenya, Italy,Venezuela, Slovenia.All these products are manufactured in our factory located in China. So we can guarantee our quality seriously and availably. Within these four years we sell not only our products but also our service to clients throughout the world.

Related Products