The quality of the FRP mold is directly related to the performance of the product, especially in terms of deformation rate, durability, etc., which must be required first. If you do not know how to detect the quality of the mold, then please read some tips in this article.

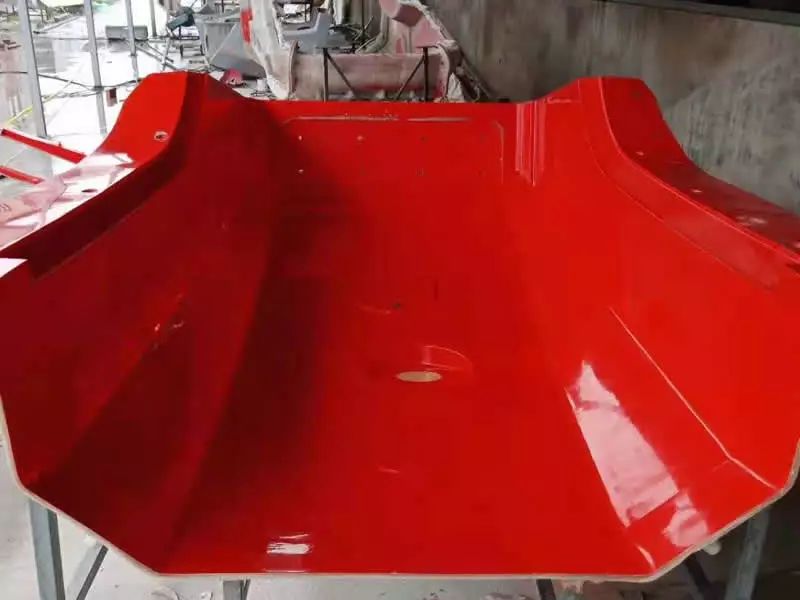

1. The surface inspection of the mold is carried out when it arrives, and it is required that there should be no visible cloth pattern on the surface;

2. The thickness of the mold gel coat is greater than or equal to 0.8mm, and the thickness of the gel coat is the thickness of the gel coat layer after curing and molding, not the thickness of the wet film;

3. There should be no resin deposition on the surface of the corner of the mold.

4. The main body of the mold, that is, the thermal deformation temperature of the FRP laminate, according to the 2001 resin parameter ≥110℃.

5. The gloss and flatness of the surface of the gel coat are required to reach the A-level surface. For the horizontal plane, the silhouette can be clearly shown without deformation.

6. Surface hardness requirements of gel coat: the average value of the bus hardness of 10 dispersion points measured by the mold body is greater than 35.

7. The surface condition of the mold requires no bubbles on the surface of the mold, no more than 3 bubbles within 1m2 of visible bubbles in the gel coat and mold laminate; no obvious brush marks, scratches and repair marks on the surface of the mold, and no more than 5 pinholes within 1m2 of the surface. A, there can be no layering phenomenon.

8. The steel frame of the mold is reasonable, and it must have an overall frame structure. The clamping platform must be firm and not easily deformed; the hydraulic device opens and closes smoothly and smoothly, the speed is adjustable, and a travel switch is provided, which can meet the opening and closing times > 1000 times in normal use.

9. The mold is designed according to the product vacuum process, the thickness of the main body is required to reach 15mm, and the thickness of the flange of the mold is required to be ≥18mm.

10. The positioning pins of the mold are metal pins, and the pins and the FRP parts should be sealed.

11. The cutting line of the mold is strictly inspected according to the product standard.

12. The matching size of the mold needs to be accurate, and the matching error between the matching parts needs to be ≤1.5mm.

13. The normal service life of the mold should not be less than 500 sets of products.

14. The flatness of the mold is ±0.5mm per linear meter, and there should be no unevenness.

15. All dimensions of the mold are guaranteed to have an error of ±1mm, and there is no burr on the surface of the laminate.

16. The surface of the mold is not allowed to have defects such as pinholes, orange peel patterns, sandpaper scratches, chicken feet cracks, etc., and the arc should be smooth transition.

17. The mold is post-cured at a high temperature of 80°C, and demolded after 8 hours.

18. The mold cannot be deformed under the exothermic peak condition of 90℃-120℃, and the surface cannot appear shrinkage marks, cracks, and inequality.

19. There should be a gap of more than 10mm between the steel frame and the mold, and the joint of the two bodies should be padded with cork or multi-layer boards of the same thickness.

20. The joint of the parting mold cannot be dislocated, the mold positioning design is reasonable, the mold is released, the product operation is simple, and the mold is easy to release.

21. The overall negative pressure of the mold is subject to 0.1, and the pressure is maintained for 5 minutes.

Post time: Mar-22-2022