E-glass Assembled Panel Roving

E-glass Assembled Panel Roving

Assembled Panel Roving is coated with a silane-based sizing compatible with UP. It can wet out fast in resin and deliver excellent dispersion after chopping.

Features

●Light weight

●High strength

●Excellent impact resistance

●No white fiber

●High translucency

Application

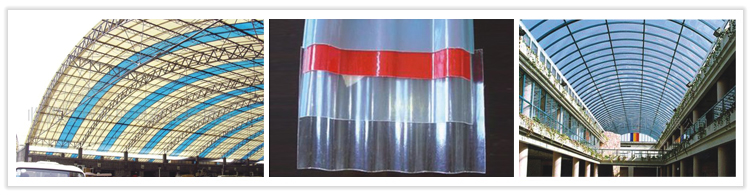

It can be used to manufacture lighting boards in building & construction industry.

Product List

|

Item |

Linear Density |

Resin Compatibility |

Features |

End Use |

|

BHP-01A |

2400, 4800 |

UP |

low static, moderate wet out, excellent dispersion |

translucent and opaque panels |

|

BHP-02A |

2400, 4800 |

UP |

extremely fast wet-out, superior transparency |

high transparency panel |

|

BHP-03A |

2400, 4800 |

UP |

low static, fast wet out, no white fiber |

general purpose |

|

BHP-04A |

2400 |

UP |

good dispersion, good anti-static property, excellent wet-out |

transparent panels |

| Identification | |

| Type of Glass |

E |

| Assembled Roving |

R |

| Filament Diameter, μm |

12, 13 |

| Linear Density, tex |

2400, 4800 |

| Technical Parameters | |||

|

Linear Density (%) |

Moisture Content (%) |

Size Content (%) |

Stiffness (mm) |

|

ISO 1889 |

ISO 3344 |

ISO 1887 |

ISO 3375 |

|

±5 |

≤0.15 |

0.60±0.15 |

115±20 |

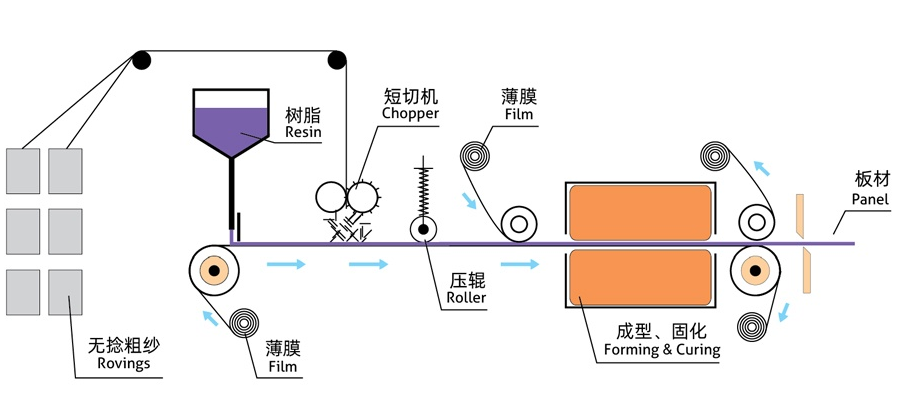

Continuous Panel Moulding process

A resin mix is uniformly deposited in a controlled amount onto the moving film at the constant speed . The thickness of the resin is controlled by the draw-knife . The fiberglass roving is chopped and uniformly distributed onto the resin, then a top film is applied forming a sandwich structure . The wet assembly travels through the curing oven to form the composite panel.