-

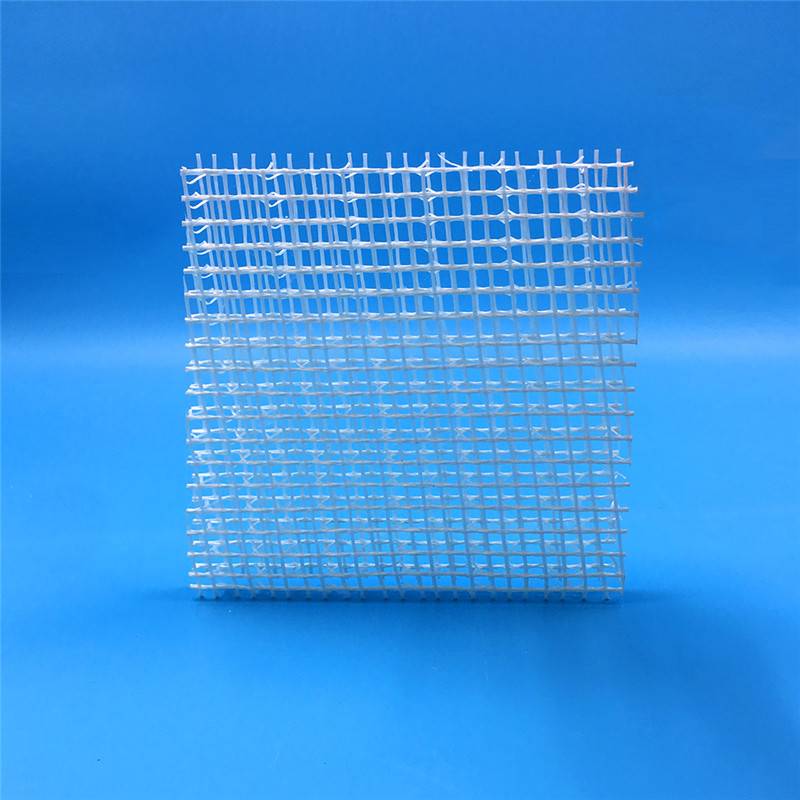

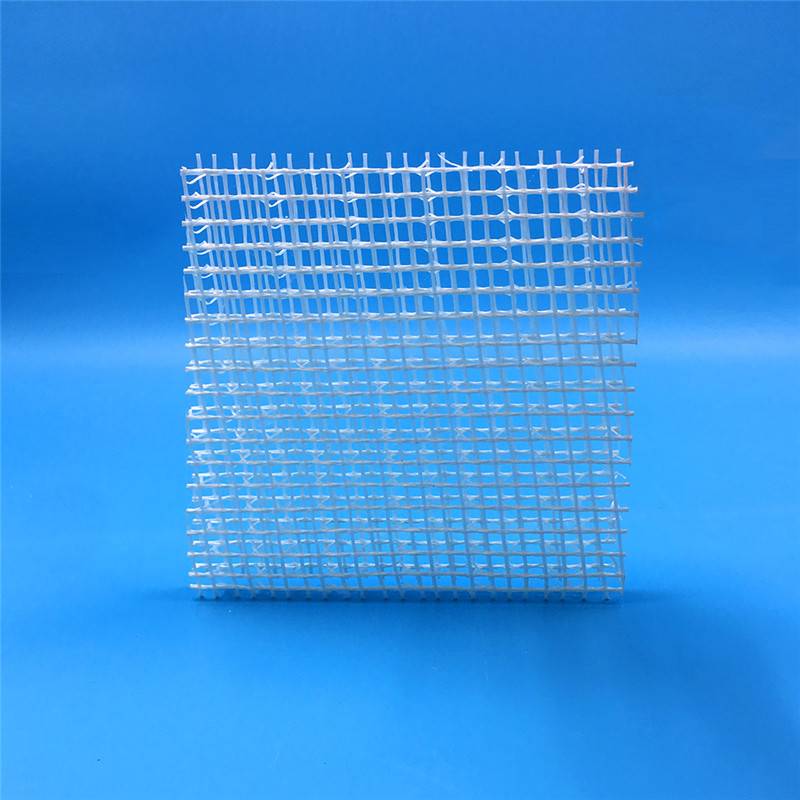

3D Fiberglass Woven Fabric

The 3-D spacer fabric consists of two bi-directional woven fabric surfaces, which are mechanically connected with vertical woven piles.

And two S-shaped piles combine to form a pillar, 8-shaped in the warp direction and 1-shaped in the weft direction. -

3D FRP Sandwich Panel for portable house/mobile barracks/camping houses

Ultra-efficient templated folding movable barracks, compared with the traditional one-vehicle can only ship a container-type barracks, our modular folding barracks transport volume is greatly reduced, a 40-foot container can be assembled with ten standard rooms, and each standard room can be set up with 4-8 beds, which can satisfy the accommodation needs of 80 people at the same time, and it has the characteristics of ultra-high-efficiency transport and so on. -

3D Air Fiber

Manufacturer Wholesale Custom Shape Luxury Bed Cervical Medical Ergonomic Air Fibre Pillow for Sleeping -

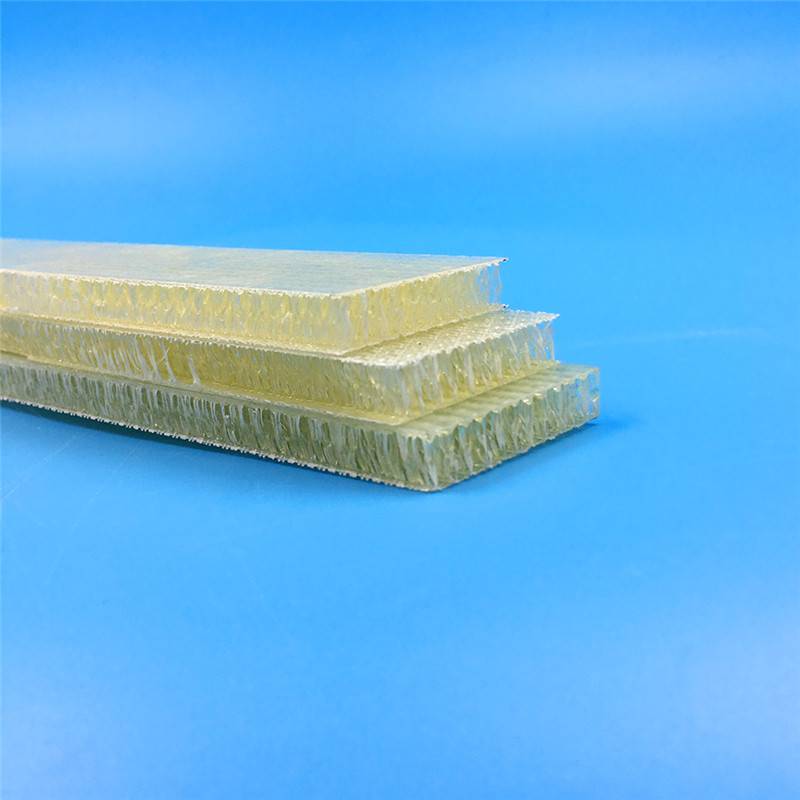

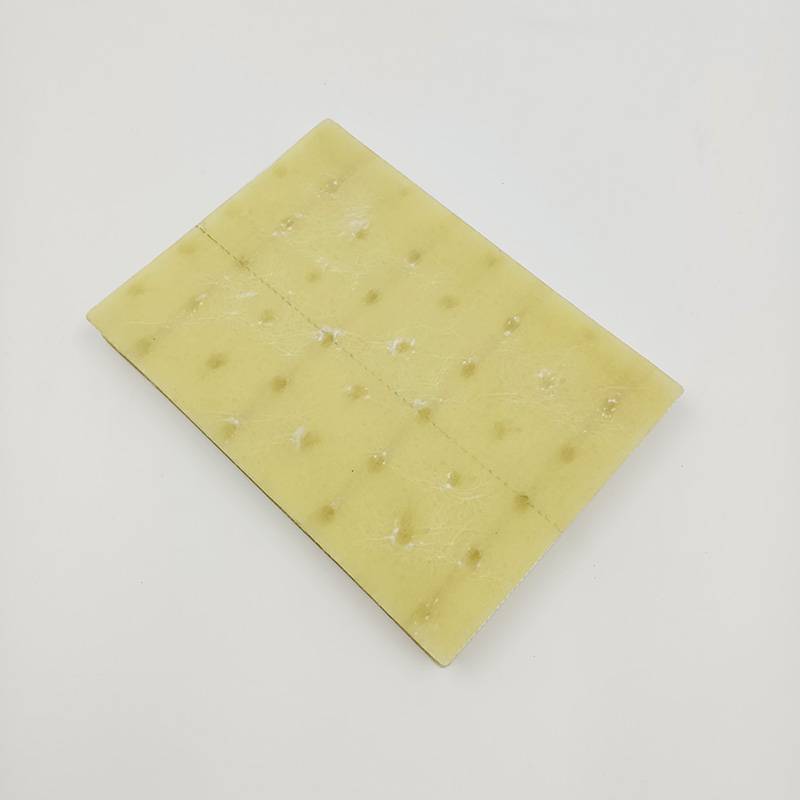

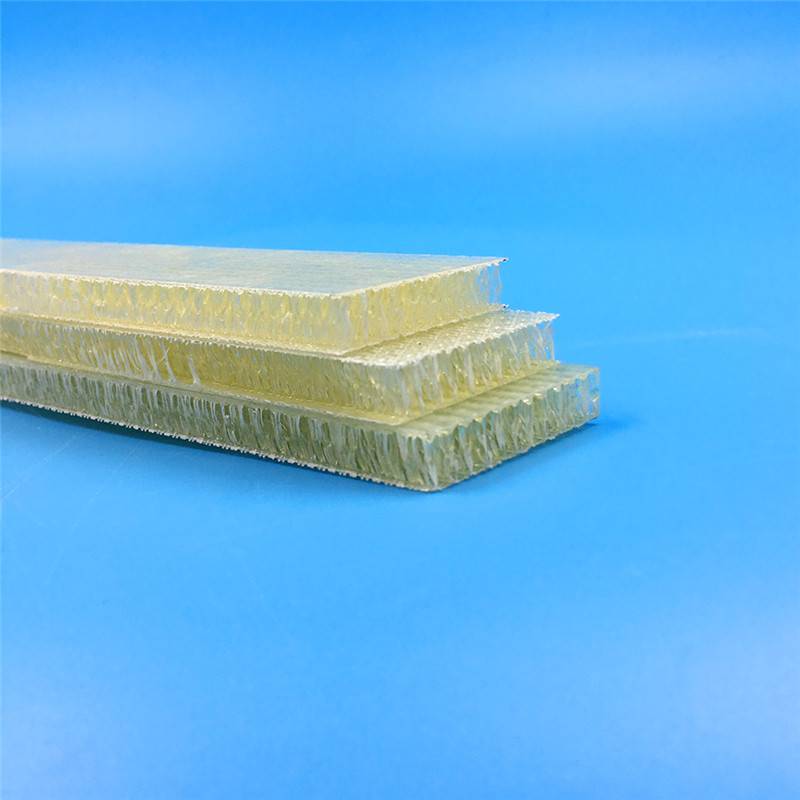

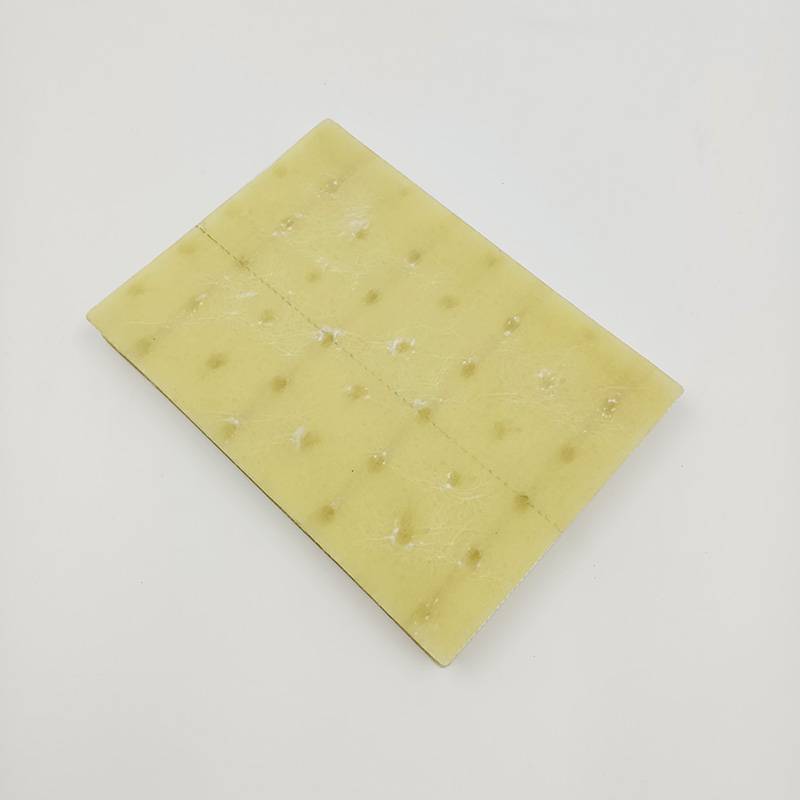

3D FRP Panel with resin

The 3-D Fiberglass Woven fabric can composite with different resins(polyester,Epoxy,Phenolic and etc), then the final product is 3D composite panel. -

3D FRP Sandwich Panel

It is new process,can produce high strength and density of homogeneous composite panel.

Sew highdensity PU plate into the special 3 d fabric, through the RTM (vacuum moldig process). -

3D Inside Core

Use Alkali resistant fiber

The 3D GRP inside core brush with glue,then fixed molding.

Second put it in mould and foaming.

The final product is 3D GRP foam concrete board.