-

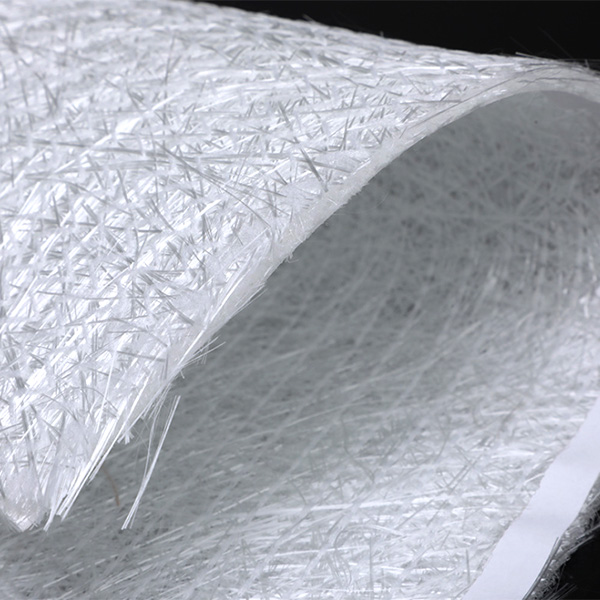

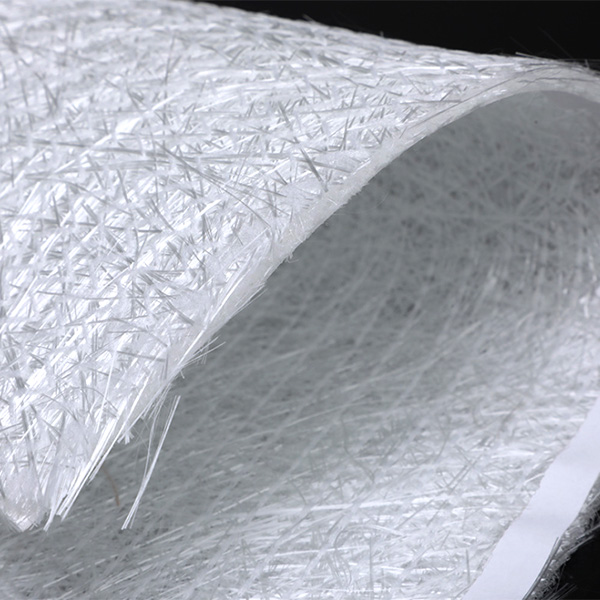

PP Core Mat

1.Items 300/180/300,450/250/450,600/250/600 and etc

2.Width: 250mm to 2600mm or sub multiple cuts

3.Roll Length:50 to 60 meters according to the areal weight -

Triaxial Fabric Longitudinal Triaxial(0°+45°-45°)

1.Three layers of roving can be stitched, however a layer of chopped strands(0g/㎡-500g/㎡) or composite materials can be added.

2.The maximal width can be 100 inches.

3.Used in blades of wind power turbines, boat manufacturing and sports advices. -

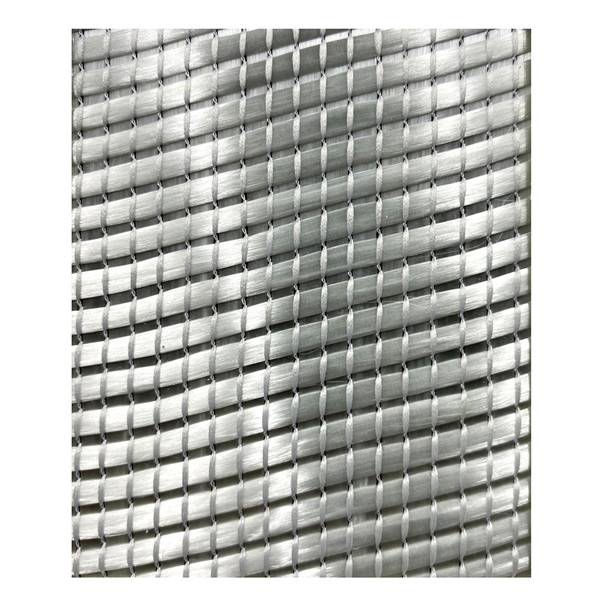

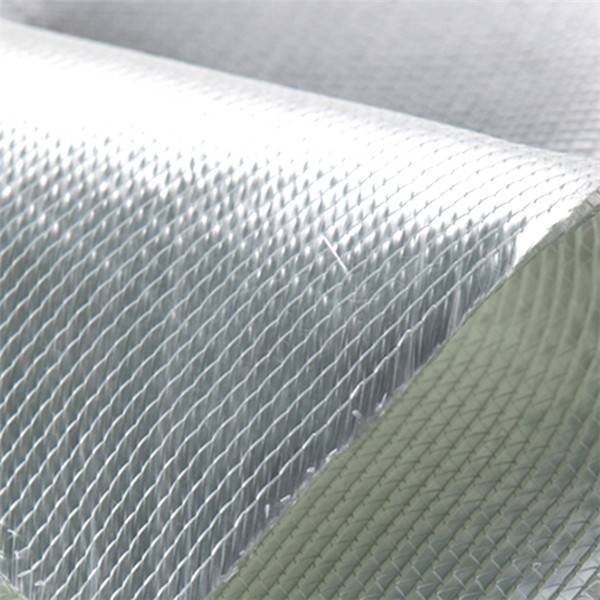

Biaxial Fabric +45°-45°

1.Two layers of rovings(450g/㎡-850g/㎡)are aligned at +45°/-45°

2.With or without a layer of chopped strands(0g/㎡-500g/㎡).

3.Maximum width of 100 inches.

4.Used in boat manufacturing. -

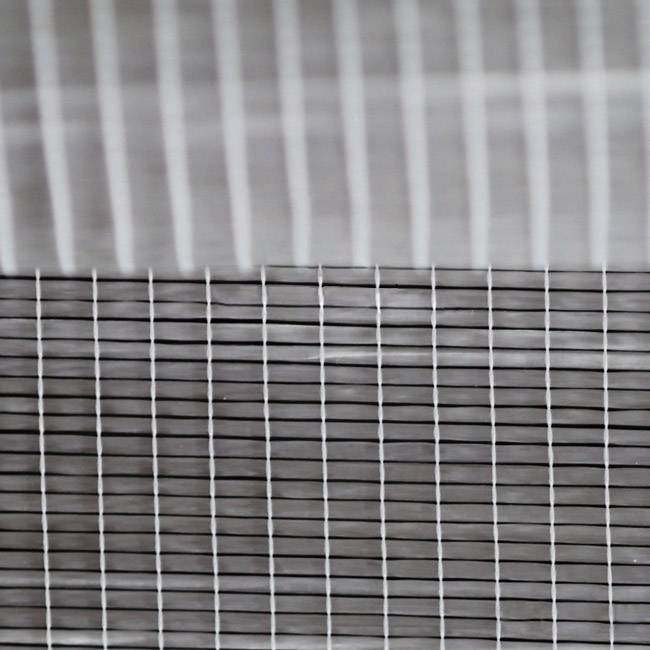

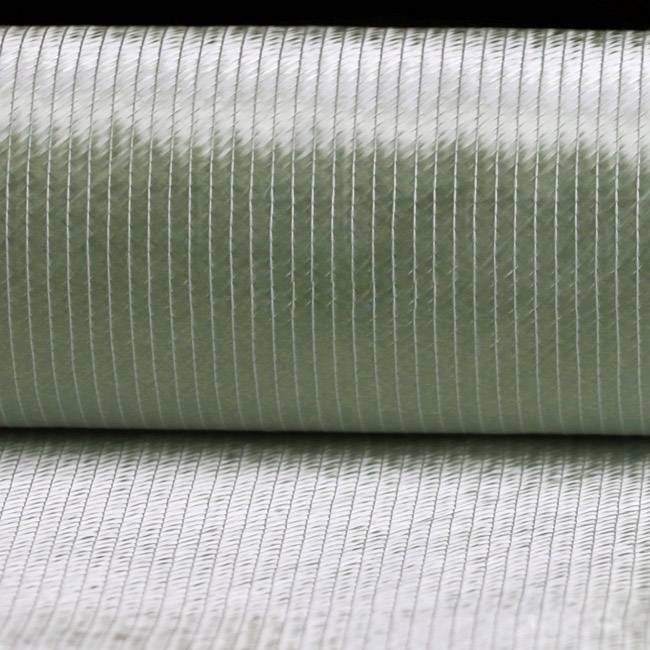

Biaxial Fabric 0°90°

1.Two layers of roving(550g/㎡-1250g/㎡)are aligned at +0°/90°

2.With or without a layer of chopped strands(0g/㎡-500g/㎡)

3.Used in boat manufacturing and automotive parts. -

Triaxial Fabric Transverse Trixial(+45°90°-45°)

1.Three layers of roving can be stitched, however a layer of chopped strands(0g/㎡-500g/㎡) or composite materials can be added.

2.The maximal width can be 100 inches.

3.It is used in blades of wind power turbines, boat manufacturing and sports advices. -

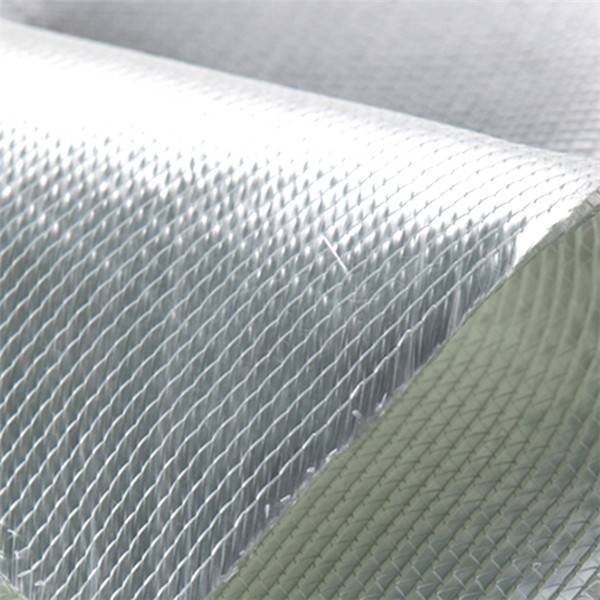

Quataxial(0°+45°90°-45°)

1.At most 4 layers of roving can be stitched, however a layer of chopped strands(0g/㎡-500g/㎡) or composite materials can be added.

2.The maximal width can be 100 inches.

3.It is used in blades of wind power turbines, boat manufacturing and sports advices. -

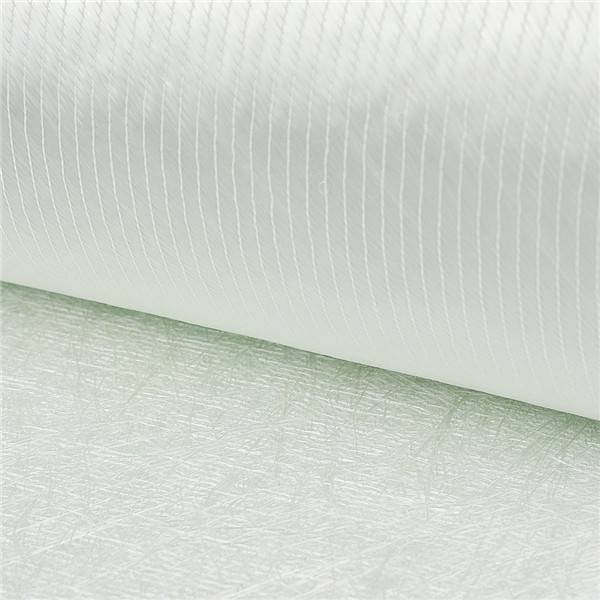

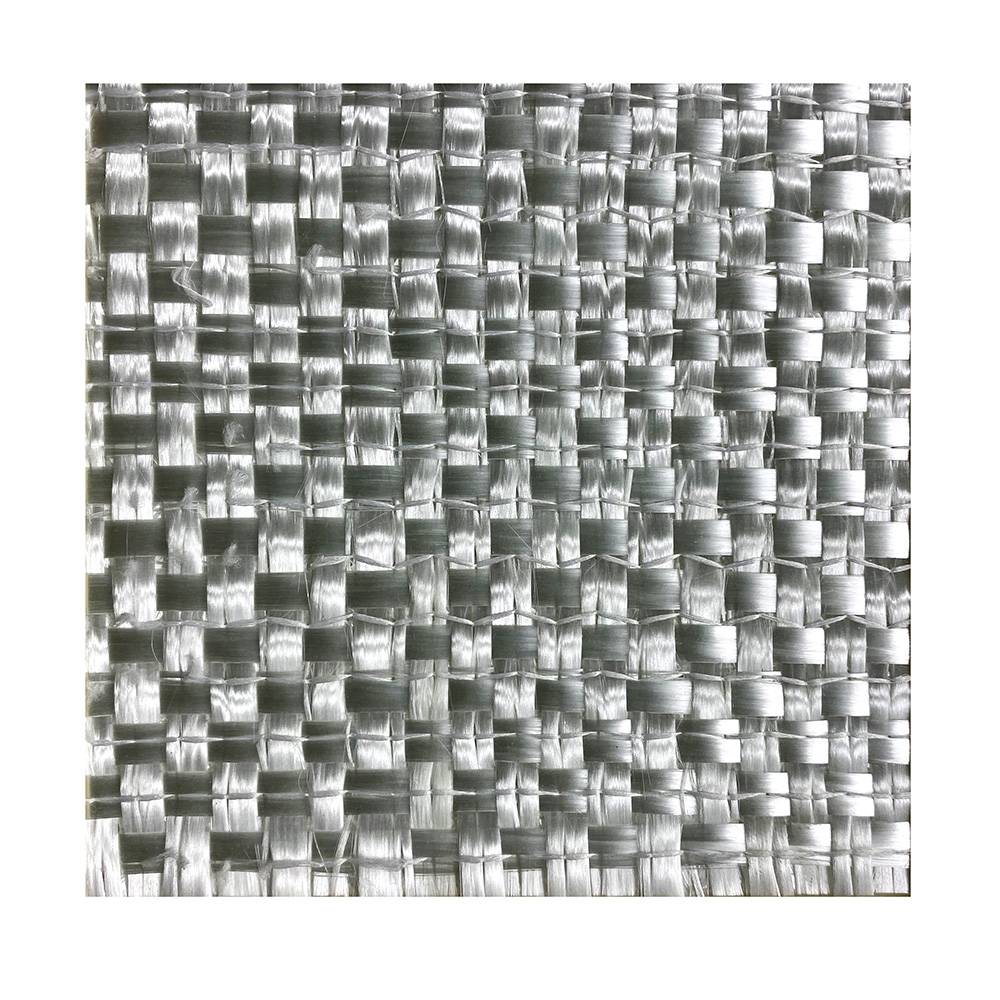

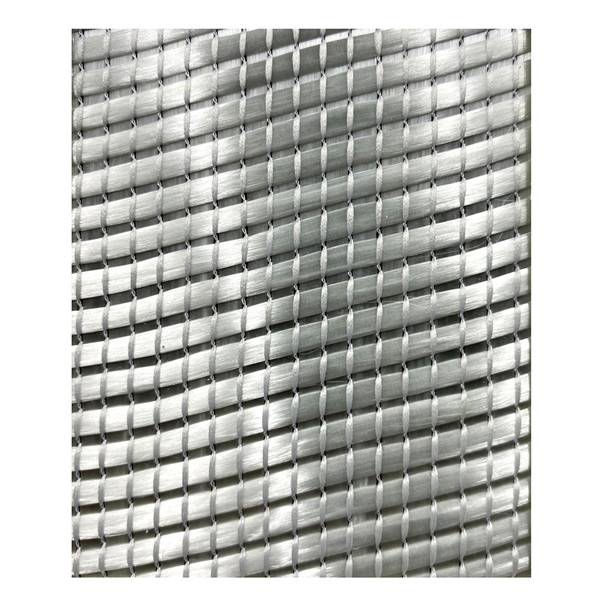

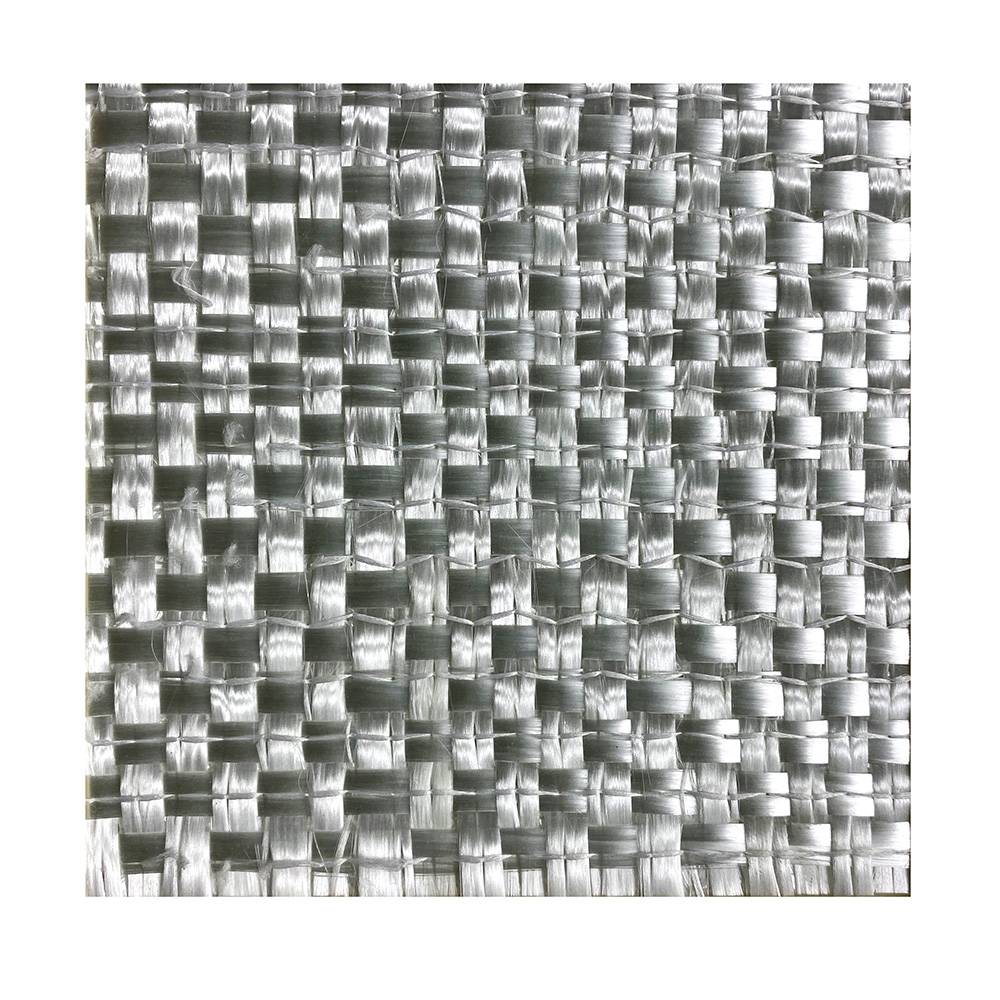

Woven Roving Combo Mat

1.It is knitted with two levels, fiberglass woven fabric and chop mat.

2.Areal weight 300-900g/m2, chop mat is 50g/m2-500g/m2.

3.Width can reach 110 inches.

4.The main usage is boating, wind blades and sport goods. -

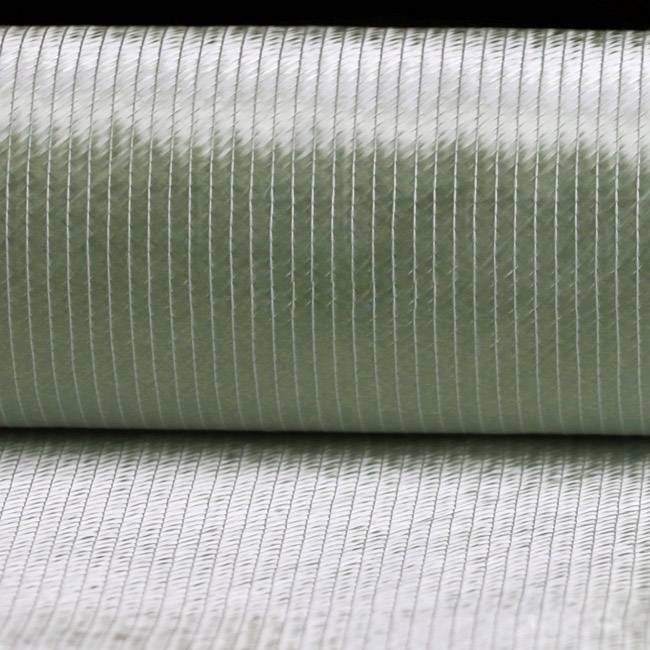

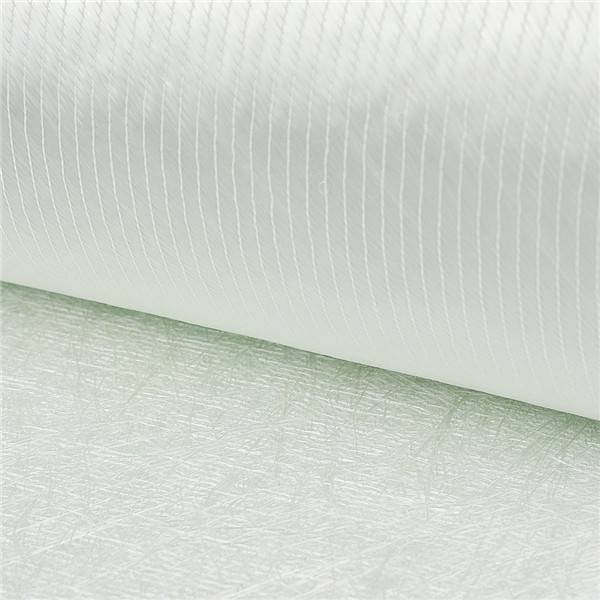

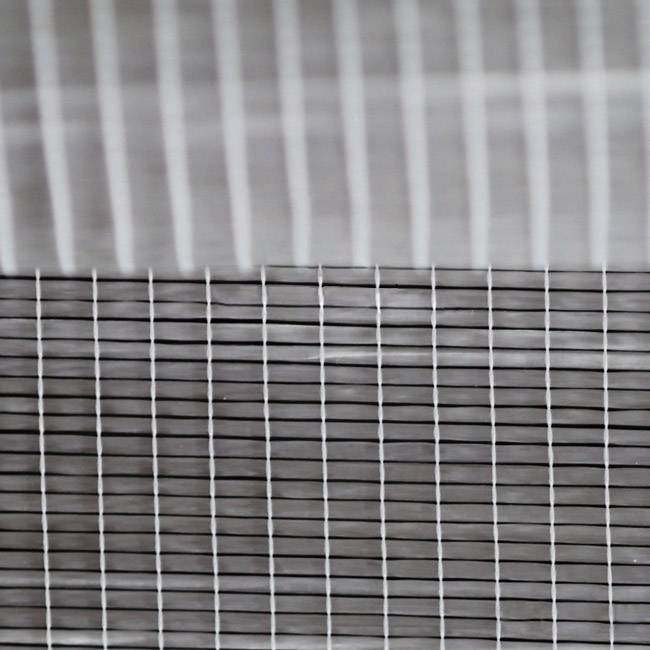

Unidirectional Mat

1.0 degree unidirectional mat and 90 degree unidirectional mat.

2.The density of 0 unidirectional mats is 300g/m2-900g/m2 and the density of 90 unidirectional mats is 150g/m2-1200g/m2.

3.It is mainly used in making tubes and blades of wind power turbines.