application field

Advanced international production technology and high quality

product section

Advanced international production technology and high quality

about company

China Beihai Fiberglass Co., Ltd.

Focus on Fiberglass & Composite Materials Manufacturing 24-hour online pre-sales and after-sales service to provide you with professional and timely response.

-

360,000tonsannual output of fiberglass roving reaches

-

66,000tonsfiberglass chopped strand mat

-

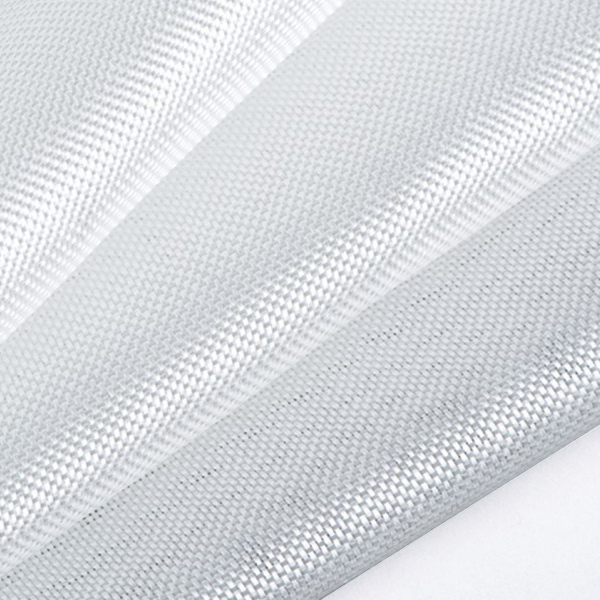

33,000tonsfiberglass woven roving

about

video

company news

read more-

Essential Guide for Wind Turbine Blade Manufacturing: Fiberglass Chopped Strand Mat Types and Selection

With the trend toward larger and offshore wind turbine blades, the stability, strength, and process compatibility of composite material systems directly determine blade lifespan and power generation efficiency. As a key reinforcing substrate for blade shells, webs, leading edges, trailing edges, ... -

Differences Between Fiberglass Roving and Yarns and Their Production Equipment Variations

Fiberglass roving and yarn are two common forms in fiberglass product manufacturing, exhibiting distinct differences in their applications, characteristics, and production processes. This article explores the distinctions between fiberglass roving and yarn, analyzing their differences in producti... -

What is the Hand Lay-up Process Using Fiberglass Chopped Strand Mat?

Pre-Construction Preparation Material Inspection Confirm glass fiber chopped strand mat is free of oil contamination, damage, or delamination; fibers are evenly distributed. Verify resin type compatibility (commonly unsaturated polyester, epoxy, vinyl ester). Adhesives are typically powder or emu... -

Advantages and Disadvantages of Autoclave Molding Process, Application Fields, and Operational Steps

The autoclave process involves laying up prepregs according to layup specifications within a mold, sealing them in a vacuum bag, and then placing the assembly into an autoclave. Through heating and pressurization within the autoclave equipment, the material undergoes a curing reaction, transformi... -

Applications of Composite Materials in Helicopters

As early as the 1950s, glass fiber reinforced composites were used in non-load-bearing components of helicopter airframes, such as fairings and inspection hatches, though their application was quite limited. The breakthrough advancement in composite materials for helicopters occurred in the 1960s... -

Project Success: BH4330-2 Phenolic Moulding Compound Sheets Shipped to United Arab Emirates (UAE)

Phenolic moulding compound (AG-4V) is a glass fiber reinforced plastic molding compound based on modified Phenolic resin. It possesses extremely high mechanical strength, heat resistance, and excellent electrical insulation properties. Various industrial components produced through hot compressio... -

How to Test the Quality of Phenolic Moulding Compounds

Quality inspection of phenolic moulding compounds (made from phenolic resin matrix with added fillers, curing agents, lubricants, etc., primarily used for compression molding) must cover core dimensions including appearance, processing performance, physical and mechanical properties, thermal prop... -

Phenolic Moulding Compound Product Types and Application Fields

Phenolic moulding compounds are categorized into two types based on differences in forming processes: Compression Moulding Compounds: Processed through compression moulding, where material is placed into a mold and subjected to high temperature and pressure (typically 150-180°C, 10-50 MPa) to ach... -

Strategies for improving glass fiber performance through sizing agent coating processes

1. Development and Application of Nanoscale Sizing Agent Precision Coating Technology Nanoscale sizing agent precision coating technology, as a cutting-edge technology, plays a crucial role in improving the performance of glass fibers. Nanomaterials, due to their large specific surface area, stro...