-

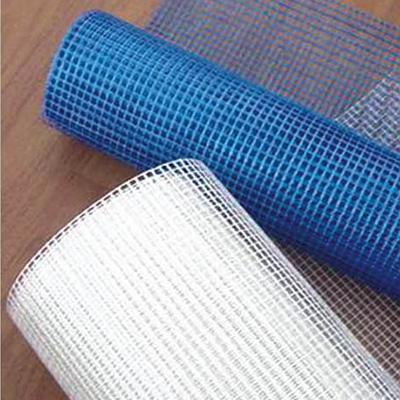

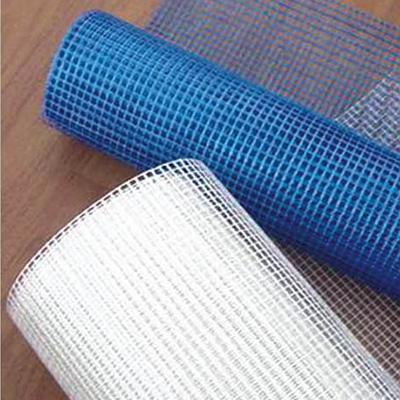

Fiberglass mesh

The alkali-proof fiberglass mesh uses the machine-woven material of central-alkali and or non-alkali as material and treats with alkali-proof coating.The strength, bonding, smoothness and fixing of the product are very well.It is widely used for reinforcement of walls, keeping warm exterior walls and water-proof of building roofs, other than are the wall reinforcement of cement, plastic asphalt, marble, mosaic and soon.It is an ideal material for construction. -

3D Panoramic Laser Scanner

Beihai 3D Panoramic Laser Scanner (Hardware) & Horizontal Tank Volumetric -

E glass heat resistant fiberglass reinforcement needle mat

Needle mat is a new fiberglass reinforcement product. It's made from continuous fiberglass strands or chopped fiberglass strands randomly looped and laid on a conveyer belt, then needle stitched together. -

High strength bidirectional e glass woven fiberglass roving fabric

E-Glass Woven Roving is bidirectional fabric made by interweaving direct roving. E-Glass Woven Roving is compatible with

many resin systems such as polyester, vinyl ester, epoxy and phenolic resins. -

High Stiffness of 3D Woven Fabric

The 3-D spacer fabric composites can provide high skin-core debonding resistance and impact resistance and impact resistance, light weight. high stiffness, excellent thermal insulation, acoustic damping, and so on. -

E-Glass 2400 tex Filament Gypsum Rovings Spray-Up Multi-End Plied Glass Fiber direct Roving yarn

Assembled Roving for spray-up is compatible with UP and VE resins. It delivers properties of low static, excellent dispersion, and good wet out in resins. Product Features: 1) Low static. 2) Excellent dispersion. 3) Good wet-out in resins. Item Linear Density Resin Compatibility Features End Use BHSU-01A 2400, 4800 UP, VE fast wet out, easy roll-out, optimum dispersion bathtub, supporting components BHSU-02A 2400, 4800 UP, VE ... -

3d Fiberglass Woven Fabric with High Strength

3-D spacer fabric construction is a newly developed concept. The fabric surfaces are strongly connected to each other by the vertical pile fibers which are interwoven with the skins. Therefore, the 3-D spacer fabric can provide good skin-core debonding resistance, excellent durability and superior integrity.

-

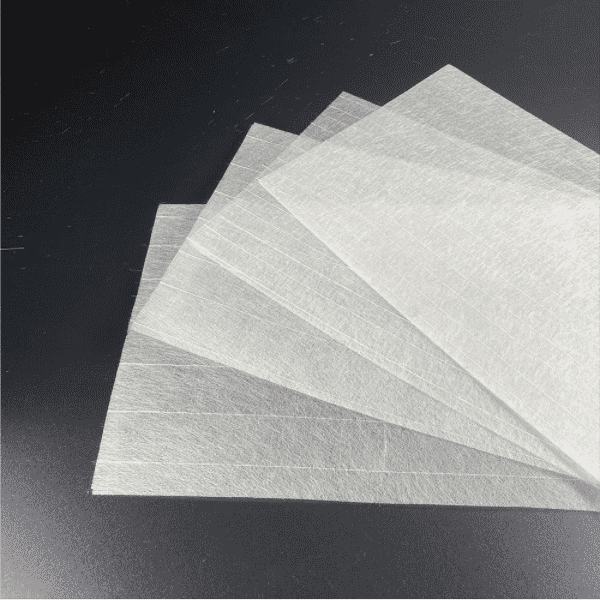

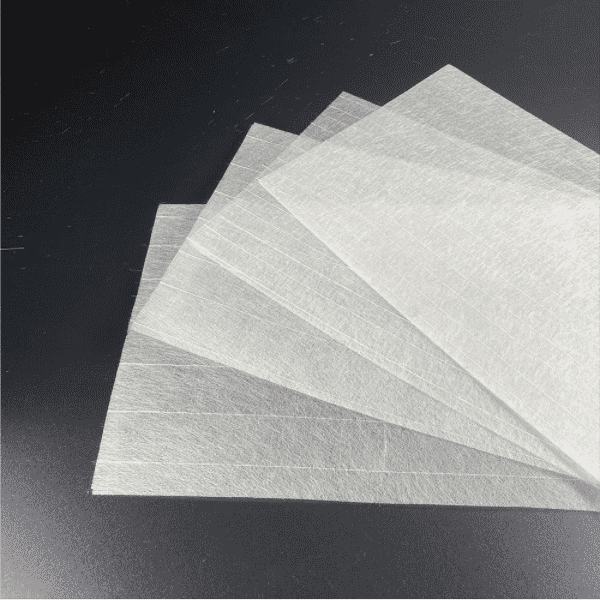

Fiberglass Wall Covering Tissue Mat

1.A environment-friendly product made of chopped fiber glass by wet process

2.Mainly applied for the surface layer and the inner layer of wall and ceiling

.Fire-retardancy

.Anti-corrosion

.Shock-resistance

.Anti-corrugation

.Crack-resistance

.Water-resistance

.Air-permeability

3.Widely used in public entertainment place, conference hall, star-hotel, restaurant, cinema, hospital, school, office building and resident house.. -

Cenosphere (Microsphere)

1.Fly ash hollow ball that can float on the water.

2.It is grayish white, with thin and hollow walls, light weight, bulk weight 250-450kg/m3,and particle size about 0.1 mm.

3.Widely used in the production of light weight castable and oil drilling and in various industries. -

BMC

1.Secially designed for reinforcing unsaturated polyester, epoxy resin and phenolic resins.

2.Widely used in transportation, construction, electronics,chemical industry and light industry. Such as the automotive parts, insulator and switch boxes. -

Fiberglass Roofing Tissue Mat

1.Mainly used as excellent substrates for waterproof roofing materials.

2.High tensile strength, corrosion resistance, easy soakage by bitumen, and so on.

3.Areal weight from 40gram/m2 to 100 gram /m2, and the space between yarns is 15mm or 30mm (68 TEX) -

Fiberglass Surface Tissue Mat

1.Mainly used as the surface layers of FRP products.

2.Uniform fiber dispersion, smooth surface, soft hand-feeling, lowbinder content, fast resin impregnation and good mould obedience.

3.Filament winding type CBM series and hand lay-up type SBM series