-

Fiberglass Needle Mat

1.Advantages of high temperature resistance, corrosion resistance, dimensional stability, low elongation shrinkage and high strength,

2.Made from single fiber, three-dimensional microporous structure, high porosity, little resistance to gas filtration.It is a high-speed,high-efficiency high-temperature filter material. -

Basalt Fibers

Basalt fibers are continuous fibers made by high-speed drawing of platinum-rhodium alloy wire-drawing leak plate after basalt material is melted at 1450 ~1500 C.

Its properties are between high-strength S glass fibers and alkali-free E glass fibers. -

Direct Roving For Filament Winding

1.It is compatible with unsaturated polyester, polyurethane, vinyl ester, epoxy and phenolic resins.

2.Main uses include manufacture of FRP pipes of various diameters, high-pressure pipes for petroleum transitions, pressure vessels, storage tanks, and,insulation materials such as utility rods and insulation tube. -

3D FRP Sandwich Panel

It is new process,can produce high strength and density of homogeneous composite panel.

Sew highdensity PU plate into the special 3 d fabric, through the RTM (vacuum moldig process). -

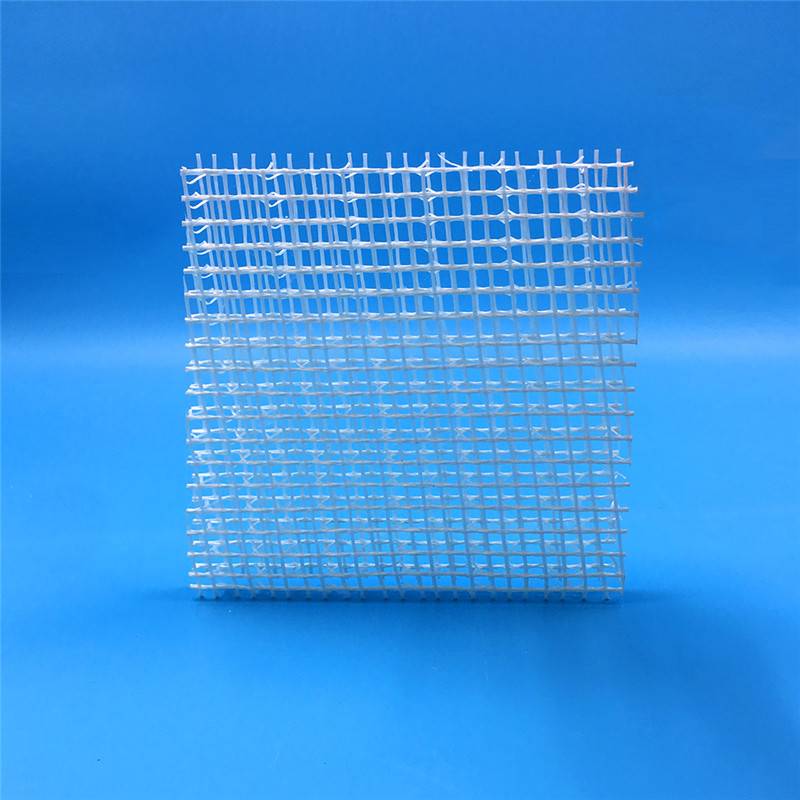

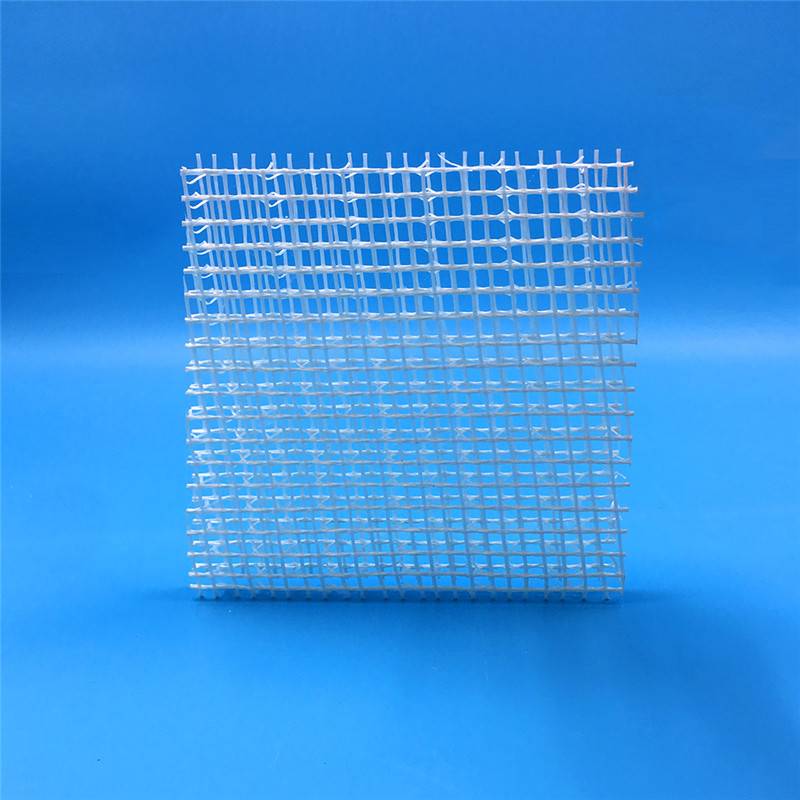

3D Inside Core

Use Alkali resistant fiber

The 3D GRP inside core brush with glue,then fixed molding.

Second put it in mould and foaming.

The final product is 3D GRP foam concrete board. -

Active Carbon Fiber Fabric

1.It can not only adsorb the organic chemistry substance, but also can filtrate the ash in air, having the characteristics of stable dimension, low air resistance and high absorption ability.

2.High specific surface area, high strength, many small pore, large electric capacity, small air resistance, not easy to pulverize and lay and long life time. -

Activated Carbon Fiber-Felt

1.It is made of natural fiber or artificial fiber non-woven mat through charring and activation.

2.The main component is carbon, piling up by carbon chip with big specific surface-area(900-2500m2/g), pore distribution rate ≥ 90% and even aperture.

3.Compared with granular active carbon, the ACF is of bigger absorbing capacity and speed, easily regenerate with less ash, and of good electric performance, anti-hot, anti-acid, anti-alkali and good at forming. -

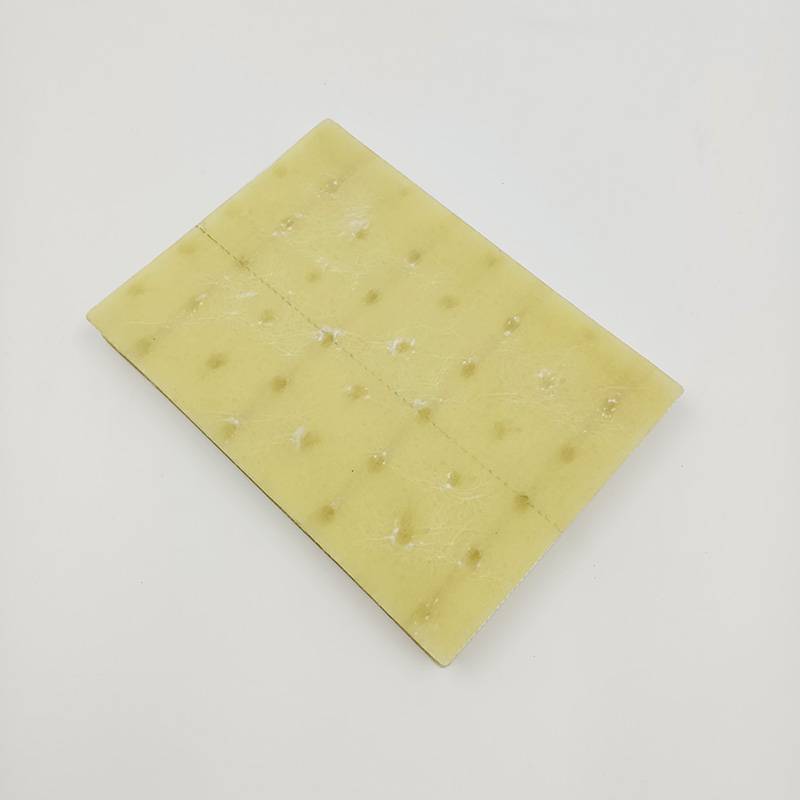

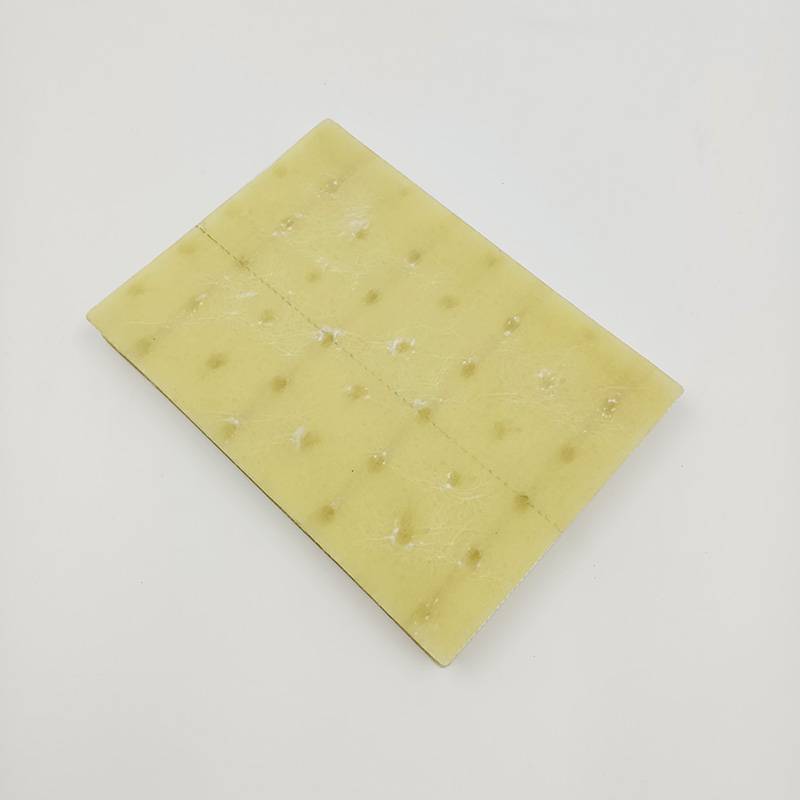

Fiberglass Chopped Strand Mat Emulsion Binder

1.It is made of randomly distributed chopped strands held tighter by a emulsion binder.

2.Compatible with UP, VE, EP resins.

3.The roll width ranges from 50mm to 3300mm. -

E-glass Stitched Chopped Strand Mat

1.Areal weight (450g/m2-900g/m2) made by chopping continuous strands into chopped strands and stitching together.

2.Maximum width of 110 inches.

3.Can be used in manufacturing boat manufacturing tubes. -

Chopped Strands for Thermoplastics

1.Based on silane coupling agent and special sizing formulation, compatible with PA,PBT/PET, PP, AS/ABS, PC, PPS/PPO,POM, LCP.

2.Widely use for automotive,home appliance, valves, pump housings, chemical corrosion resistance and sports apparatus. -

E-glass Assembled Roving For GMT

1.Coated with a silane-based sizing compatible with PP resin.

2.Used in the GMT needed mat process.

3.The end-use applications:automotive acoustical inserts,building & construction,chemical,packing and transportation low density components. -

E-glass Assembled Roving For Chopping

1.Coated with special silane-based sizing,compatible with UP and VE, delivering relatively high resin absorbability and excellent choppability,

2.Final composite products deliver superior water resistance and excellent chemical corrosion resistance.

3.Typically used to manufacture FRP pipes.