Direct Roving For Filament Winding

Direct Roving For Filament Winding

Direct Roving for Filament winding, is compatible with unsaturated polyester, polyurethane, vinyl ester, epoxy and phenolic resins.

Features

●Good process performance and low fuzz

●Compatibillty with multiple of resin systems

●Good mechanical properties

●Complete and fast wet-out

●Excellent acid corrosion resistance

Application

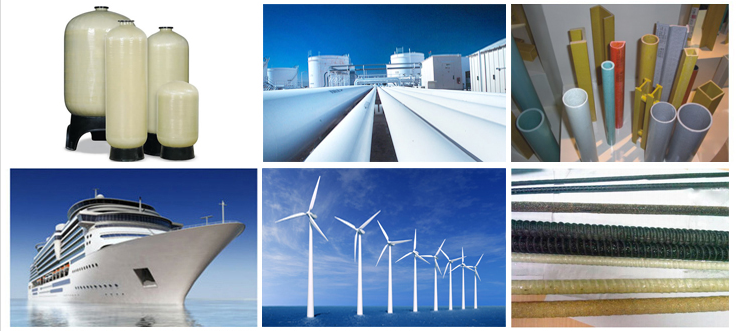

Main uses include manufacture of FRP pipes of various diameters, high-pressure pipes for petroleum transitions, pressure vessels, storage tanks, and, insulation materials such as utility rods and insulation tube.

Product List

|

Item |

Linear Density |

Resin Compatibility |

Features |

End Use |

|

BHFW-01D |

1200,2000,2400 |

EP |

Compatible with epoxy resin, designed for filament winding process under high tension |

used as reinforcement to manufacture high pressure pipe for petroleum transmission |

|

BHFW-02D |

2000 |

Polyurethane |

Compatible with epoxy resin, designed for filament winding process under high tension |

Used to manufacture utility rods |

|

BHFW-03D |

200-9600 |

UP,VE,EP |

Compatible with resins; Low fuzz; Superior processing property; High mechanical strength of the composite product |

Used to manufacture storage tanks and medial-pressure FRP pipes for water transmission and chemical corrosion |

|

BHFW-04D |

1200,2400 |

EP |

Excellent electrical property |

Used to manufacture hollow insulation pipe |

|

BHFW-05D |

200-9600 |

UP,VE,EP |

Compatible with resins; Excellent mechanical properties of the composite product |

Used to manufacture normal pressure-resistant FRP pipes and storage tanks |

|

BHFW-06D |

735 |

UP,VE,UP |

Excellent process performance; Excellent chemical corrosion resistance, such as crude oil and gas H2S corrosion etc; Excellent abrasion resistance |

Designed for RTP (reinforcement thermoplastics pipe) filament winding which requires acid resistance and abrasion resistance. It is suitable for application in spoolable piping systems |

|

BHFW-07D |

300-2400 |

EP |

Compatible with epoxy resin; Low fuzz; Designed for filament winding process under low tension |

used as reinforcement of pressure vessel and high- and medial- pressure resistance FRP pipe for water transmission |

| Identification | |||||||

|

Type of Glass |

E |

||||||

|

Direct Roving |

R |

||||||

|

Filament Diameter, μm |

13 |

16 |

17 |

17 |

22 |

24 |

31 |

|

Linear Density, tex |

300 |

200 400 |

600 735 |

1100 1200 |

2200 |

2400 4800 |

9600 |

| Technical Parameters | |||

|

Linear Density (%) |

Moisture Content (%) |

Size Content (%) |

Breakage Strength (N/Tex) |

|

ISO1889 |

ISO3344 |

ISO1887 |

IS03341 |

|

±5 |

≤0.10 |

0.55±0.15 |

≥0.40 |

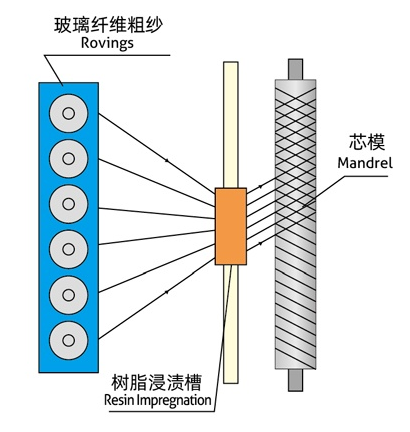

Filament Winding Process

Traditional Filament Winding

In the filament winding process , continuous strands of resin-impregnated glassfiber are wound under tension onto a mandrel in precise geometric patterns tobuild up the part which is then cured to form the finished parts.

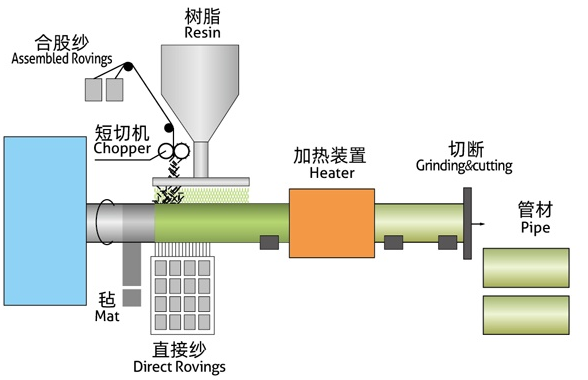

Continuous Filament Winding

Multiple laminate layers , composed of resin , reinforcement glass and other materials are applied to a rotating mandrel , which is formed from a continuous steel band continuously traveling in a cork-screw motion . The composite part is heated and cured in place as the mandrel travels through the line and then cut into a specific length with a traveling cut-off saw .