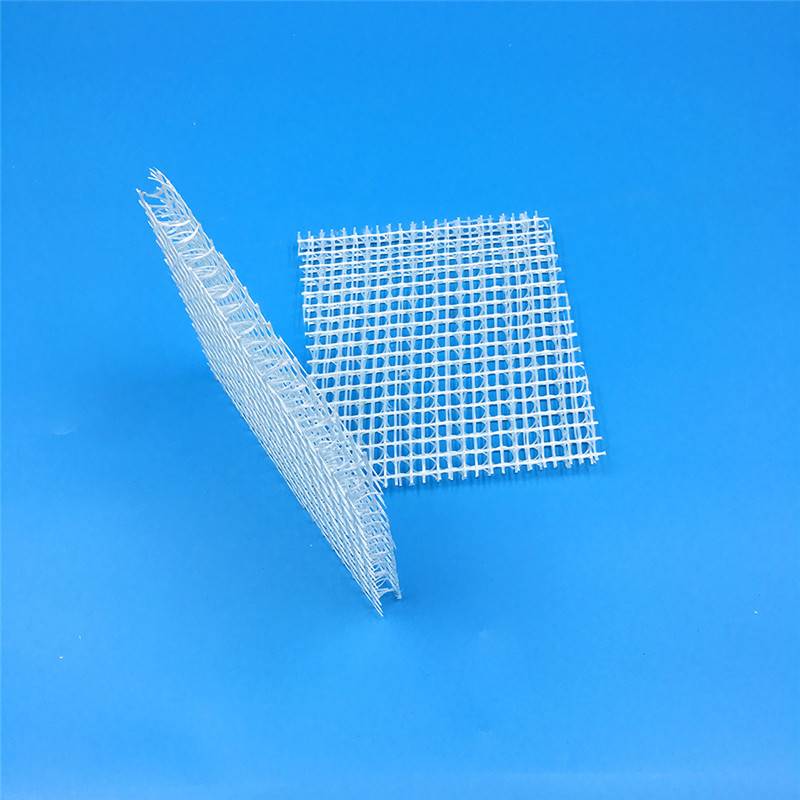

New Fashion Design for Woven Glass Fiber - 3D Inside Core – Beihai Fiberglass

New Fashion Design for Woven Glass Fiber - 3D Inside Core – Beihai Fiberglass Detail:

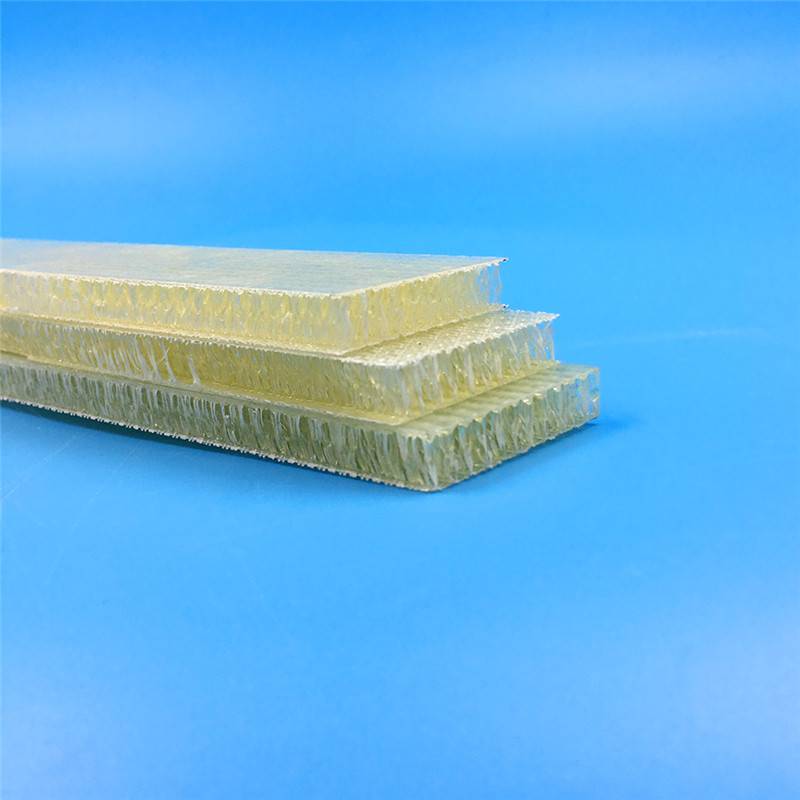

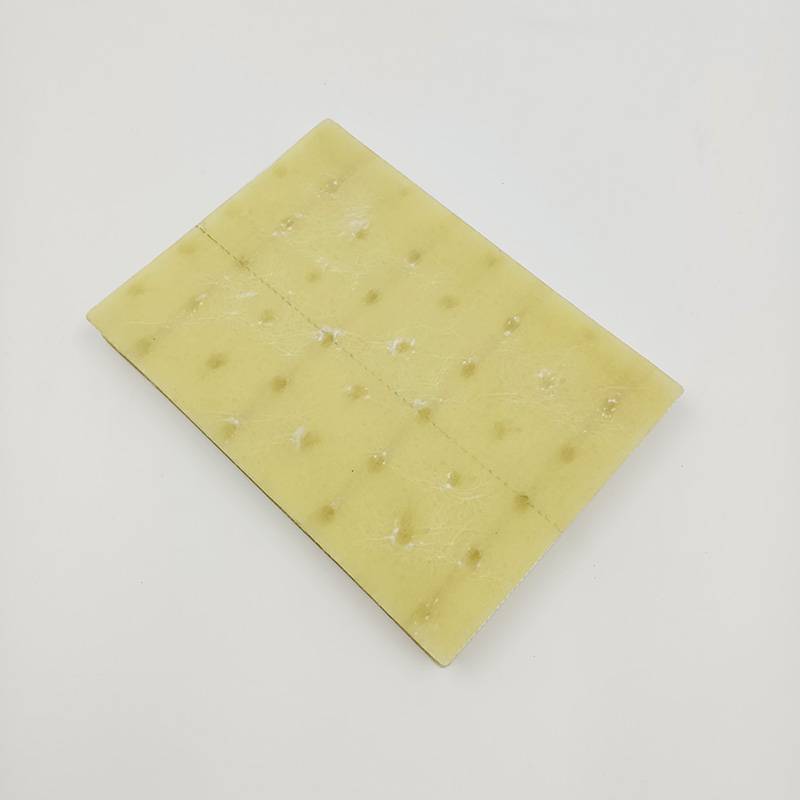

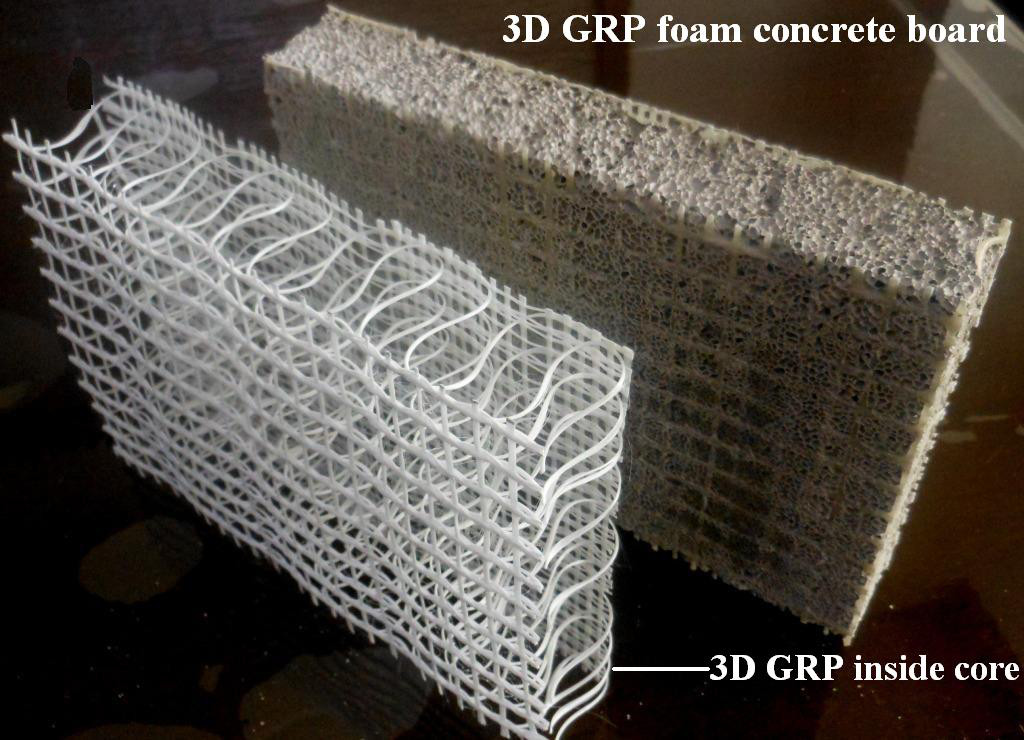

The 3D GRP inside core brush with glue,then fixed molding.Second put it in mould and foaming.The final product is 3D GRP foam concrete board.

Advantage

Solve the problem of traditional foam cement :strength low, fragile, easy to crack; greatly improve the pulls strength, compression, bending strength (tensile, compressive strength were more than 0.50MP).

With modified foaming formula, so that foam has better thermal insulation performance, lower water absorption.It is the most perfect building insulation class A1 incombustible material, same lifetime with building.

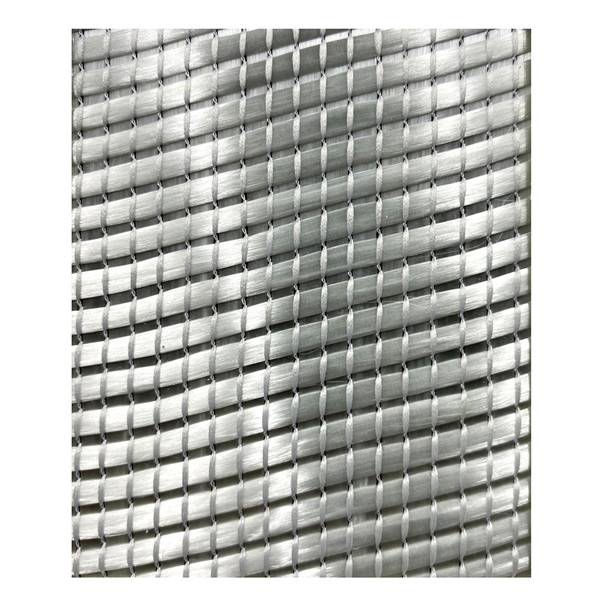

Standard width is 1300mm

Weight 1.5kg/m2

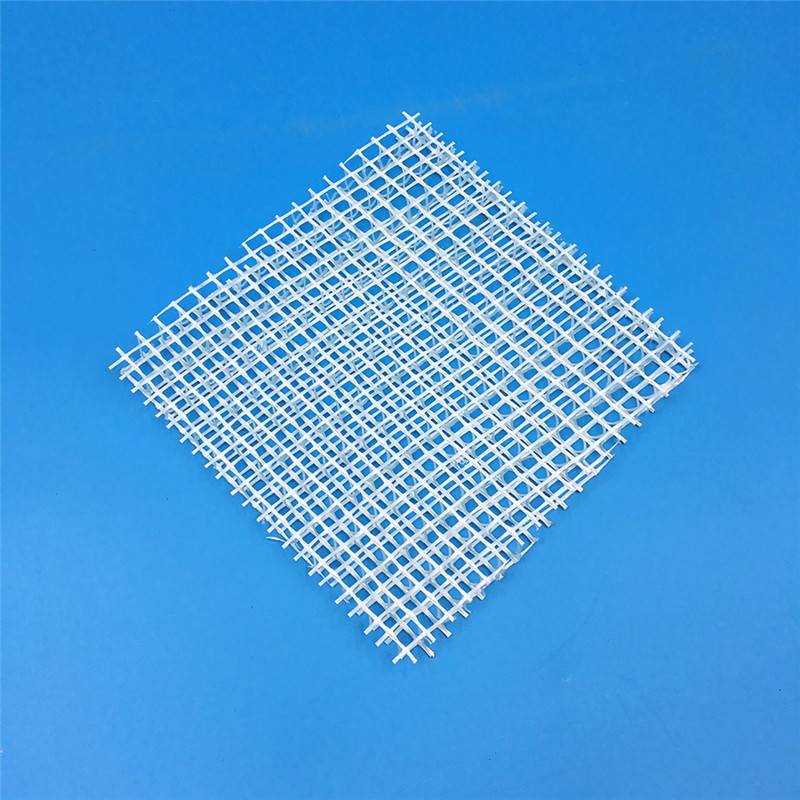

Mesh size: 9mm*9mm

Application

How to brush resin on 3D fabric

1. Resin blending: normally use unsaturated resins and need to add curing agent (100g resin with 1-3g curing agent)

2. The ratio of resin to fabric is 1:1, for instance, 1000g fabric need 1000g resin.

3.Choosing the appropriate operating platform and the fabric needs to be waxed on the surface of the operating platform( for the purpose of demoulding)

4.Putting the fabric on the operating platform.

5.Because the fabric is wrapping in the paper tubes, the core pillars will inclined to one direction.

6.We will use rolls to brush the resin along the inclined direction of the fabric so that the fabric fibers can be infiltrated.

7.After the fabric fibers are fully infiltrated, we can pull the upper layer of the fabric in the opposite direction and keep the whole fabric upright.

8.It can be used when it is completely cured.

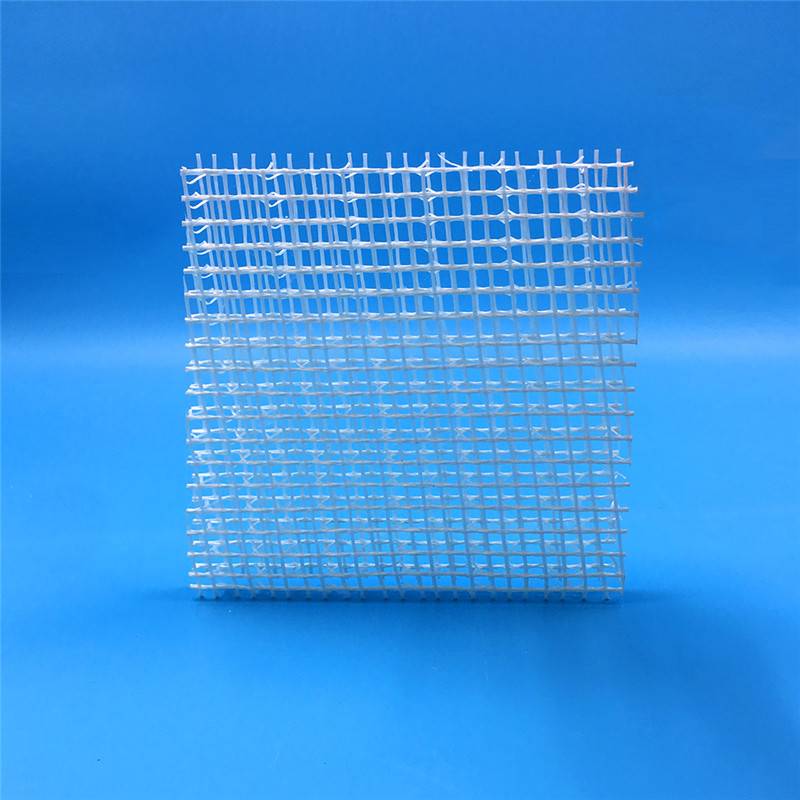

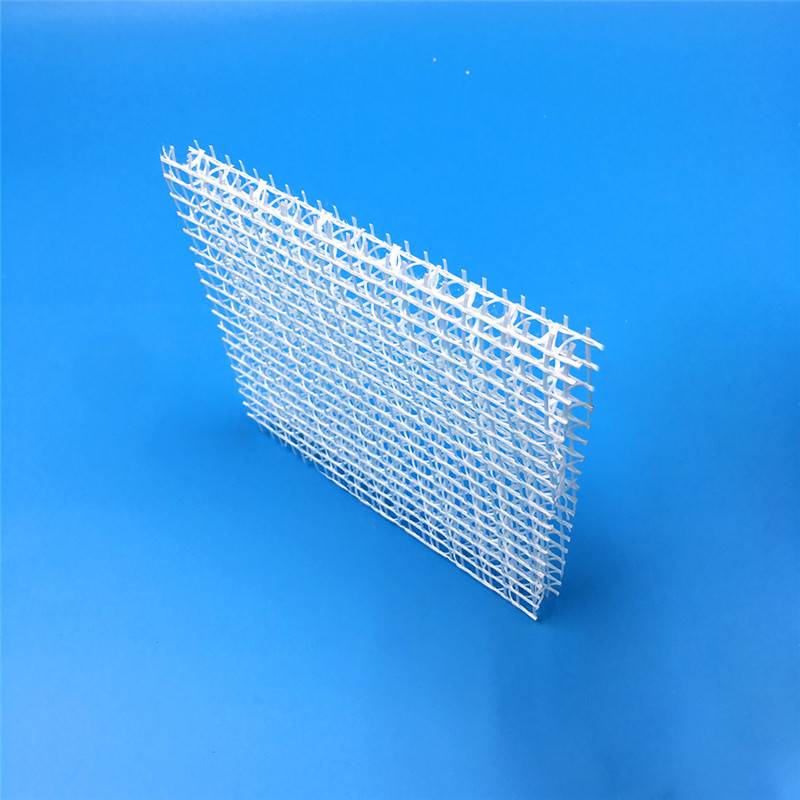

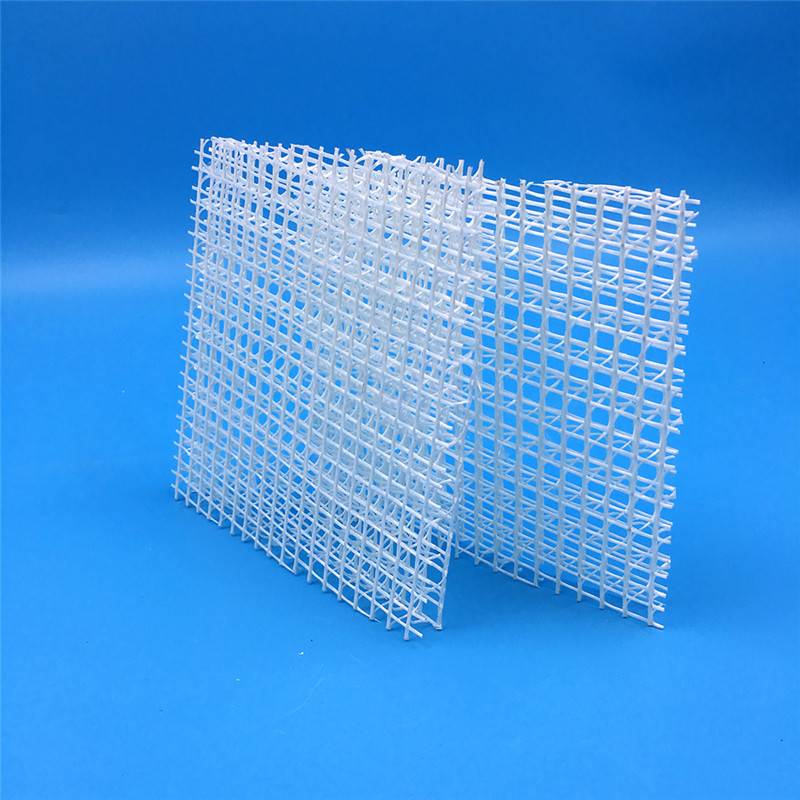

Product detail pictures:

Related Product Guide:

We believe that long expression partnership is often a result of top of the range, value added service, prosperous encounter and personal contact for New Fashion Design for Woven Glass Fiber - 3D Inside Core – Beihai Fiberglass , The product will supply to all over the world, such as: Bangkok, Singapore, Libya, We would very much welcome an opportunity to do business with you and have pleasure in attaching further details of our products. Excellent quality, competitive prices,punctual delivery and dependable service can be guaranteed.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.