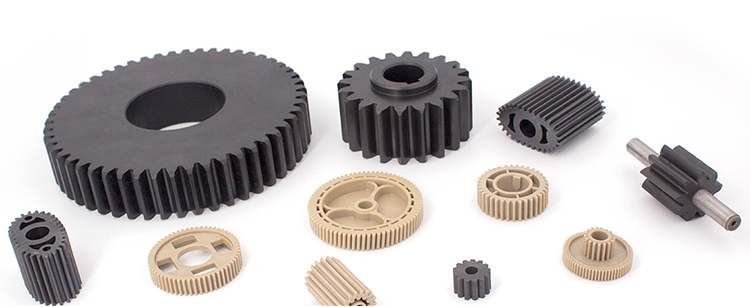

High Temperature, Corrosion Resistant, High Precision PEEK Gears

Product Description

Our PEEK gears are manufactured using state-of-the-art technology ensuring precision engineering and consistent quality. The unique combination of PEEK material and advanced manufacturing processes results in gears with excellent wear resistance, low coefficient of friction and high strength-to-weight ratio. This makes it ideal for applications where reliability and longevity are critical, such as high-load transmission systems, precision machinery and heavy equipment.

Product Advantages

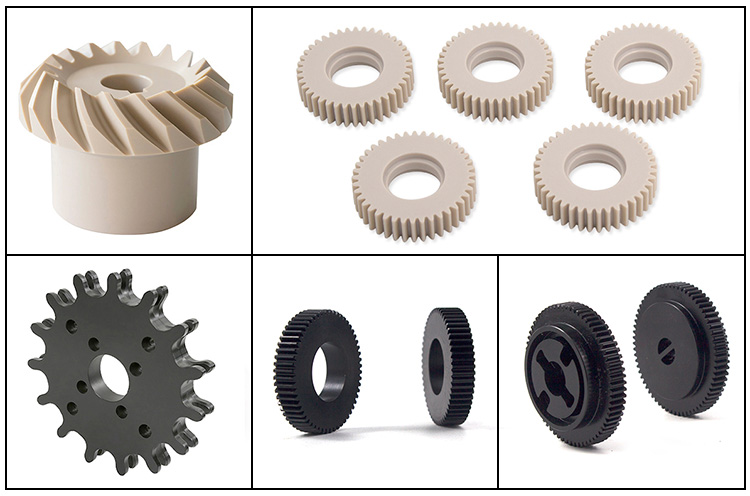

PEEK gears are designed to outperform traditional gear materials, including metals and other plastics, in terms of wear resistance, weight savings and overall performance. Its superior mechanical properties allow it to withstand extreme temperatures, corrosive chemicals and high loads without degradation, making it ideal for critical applications where failure is not tolerated. Our PEEK gears are capable of operating in harsh environments, providing unparalleled reliability and durability, reducing customer downtime and maintenance costs.

In addition to superior performance and durability, our PEEK gears are easy to install and maintain. Its lightweight and corrosion-resistant properties make it easier to handle and install, reducing labor costs and time. Additionally, its self-lubricating properties help reduce maintenance requirements, further reducing customers’ overall operating costs.

Product Specification

|

Property |

Item No. |

Unit |

PEEK-1000 |

PEEK-CA30 |

PEEK-GF30 |

|

1 |

Density |

g/cm3 |

1.31 |

1.41 |

1.51 |

|

2 |

Water absorption(23℃ in air) |

% |

0.20 |

0.14 |

0.14 |

|

3 |

Tensile strength |

MPa |

110 |

130 |

90 |

|

4 |

Tensile strain at break |

% |

20 |

5 |

5 |

|

5 |

Compressive stress(at 2%nominal strain) |

MPa |

57 |

97 |

81 |

|

6 |

Charpy impact strength (unnotched) |

KJ/m2 |

No break |

35 |

35 |

|

7 |

Charpy impact strength (notched) |

KJ/m2 |

3.5 |

4 |

4 |

|

8 |

Tensile modulus of elasticity |

MPa |

4400 |

7700 |

6300 |

|

9 |

Ball indentation hardness |

N/mm2 |

230 |

325 |

270 |

|

10 |

Rockwell hardness |

– |

M105 |

M102 |

M99 |

Product Applications

PEEK’s long-term use temperature is about 260-280 ℃, short-term use temperature can reach 330 ℃, and high pressure resistance up to 30MPa, is a good material for high-temperature seals.

PEEK also has good self-lubrication, easy processing, insulation stability, hydrolysis resistance and other excellent properties, making it in the aerospace, automotive manufacturing, electrical and electronic, medical and food processing and other fields have a wide range of applications.