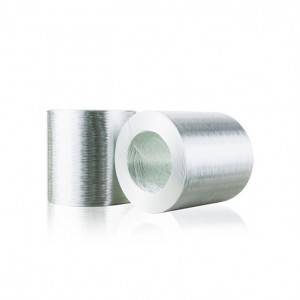

Direct Roving For Pultrusion

Direct Roving For Pultrusion

Direct Roving for Pultrusion is compatible with unsaturated polyester, vinyl ester, epoxy and phenolic resins.

Features

●Good process performance and low fuzz

●Compatibillty with multiple of resin systems

●Good mechanical properties

●Complete and fast wet-out

●Excellent acid corrosion resistance

Application:

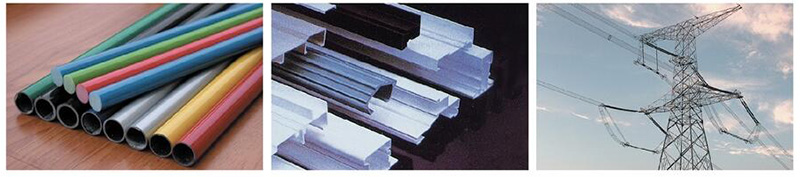

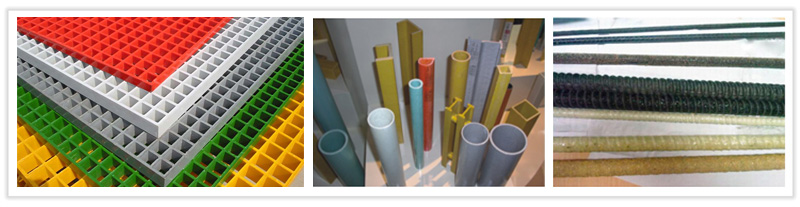

It is widely used in building & construction, telecommunication and insulator industry.

Pultrusion profiles for outdoor sports equipment,Optic cables,Various sectional bars,etc.

Product List

|

Item |

Linear Density |

Resin Compatibility |

Features |

End Use |

|

BHP-01D |

300,600,1200 |

VE |

Compatible with matrix resin; High tensile strength of the end composite product |

Used to manufacture optic cable |

|

BHP-02D |

300-9600 |

UP,VE,EP |

Compatible with matrix resin; Fast wet out; Eexcellent mechanical properties of the composite product |

Used to manufacture various sectional bars |

|

BHP-03D |

1200-9600 |

UP,VE,EP |

Compatible with resins; Excellent mechanical properties of the composite product |

Used to manufacture various sectional bars |

|

BHP-04D |

1200,2400 |

EP,Polyester |

Soft yarn; Low fuzz; Compatible with resins |

Suitable in manufacture of molded grating |

|

BHP-05D |

2400-9600 |

UP,VE,EP |

Excellent tensile, flexural and shear properties for composites products |

High performance pultruded profiles |

|

BHP-06D |

2400,4800,9600 |

EP |

High fiber strength, Good integrity and ribbonization,Compatibility with epoxy resin, Complete and fast wet-out in resins, Good mechanical properties, Excellent electrical properties of the finished |

insulation rods and insulation stanchions |

| Identification | |||||||

|

Type of Glass |

E |

||||||

|

Direct Roving |

R |

||||||

|

Filament Diameter, μm |

13 |

16 |

17 |

17 |

22 |

24 |

31 |

|

Linear Density, tex |

300 |

200 400 |

600 735 |

1100 1200 |

2200 |

2400 4800 |

9600 |

| Technical Parameters | |||

|

Linear Density (%) |

Moisture Content (%) |

Size Content (%) |

Breakage Strength (N/Tex) |

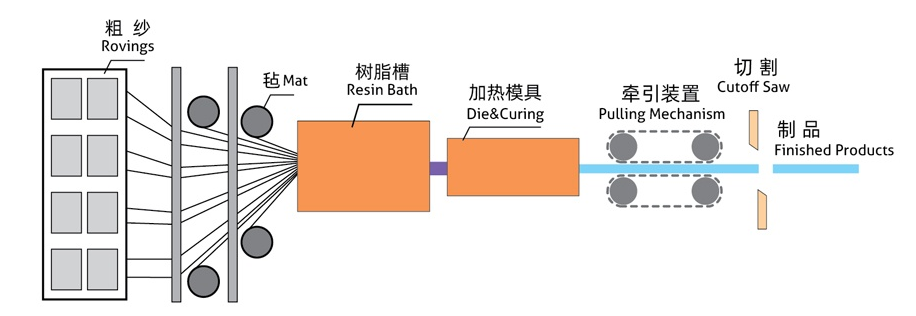

Pultrusion process

The rovings, mats or other fabrics are pulled through a resin impregnation bath and then into a heated die using a continuous pulling device. The final products are formed under high temperature and high pressure conditions.