Basalt Fiber Composite Reinforcement for Geotechnical Works

Product Description:

The use of reinforcing bar basalt fiber tendon in geotechnical engineering can effectively enhance the mechanical properties and stability of the soil body. Basalt fiber reinforcement is a kind of fiber material made of basalt raw material, with high strength, durability and corrosion resistance.

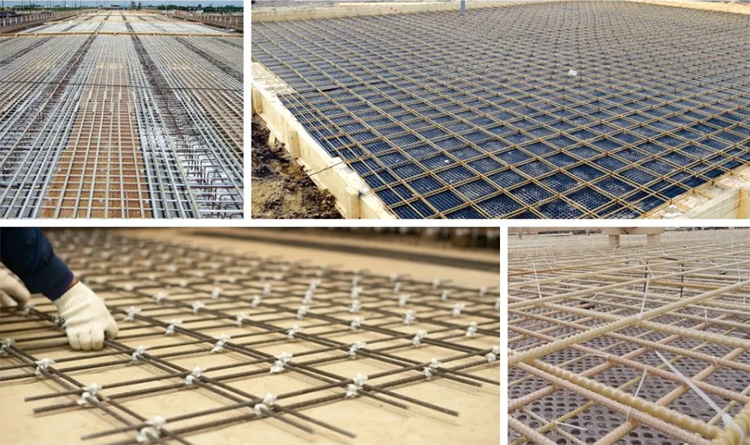

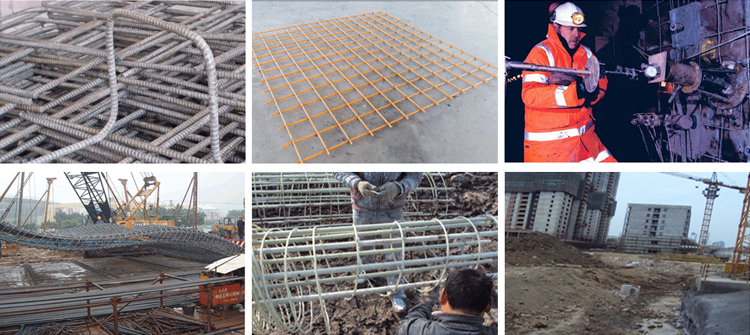

Reinforcing Basalt Fiber Rebar is commonly used in geotechnical engineering applications such as soil reinforcement, geogrids and geotextiles. It can be inserted into the soil to increase the tensile strength and crack resistance of the soil. Basalt fiber reinforcement can effectively disperse and take up the stress in the soil body, slowing down or preventing cracking and deformation of the soil body. In addition, it can improve the scouring resistance and infiltration resistance of the soil body.

Product Characteristics:

1. High strength: basalt fiber composite tendon has excellent tensile strength and bending strength. It is able to withstand tensile and shear forces in the soil body, providing reinforcement and reinforcement to improve the overall mechanical properties of the soil body.

2. Lightweight: Compared with traditional steel reinforcement, basalt fiber composite reinforcement has a lower density and is therefore lighter. This reduces the weight and labor intensity of construction and does not add excessive loads to the soil.

3. Corrosion resistance: Basalt fiber composite reinforcement has good corrosion resistance, able to resist the erosion of soil chemicals and moisture. This gives it good durability in geotechnical works in wet, corrosive environments.

4. Adjustability: basalt fiber composite tendon can be designed and adjusted according to engineering needs. Parameters such as the composition of the composite and the arrangement of the fibers can be changed to meet the requirements of different engineering projects.

5. Environmentally sustainable: Basalt fiber is a natural ore material that contains no harmful substances and has a low environmental impact. At the same time, the use of composite materials also helps to reduce the demand for traditional resources, in line with the principle of sustainable development.

Applications:

Basalt fiber composite reinforcement is widely used in geotechnical engineering for soil reinforcement, soil crack resistance, and soil seepage control. It is commonly used in soil retaining walls, slope protection, geogrids, geotextiles and other projects to provide reinforcement and stabilization of the soil body by combining with the soil body, improving the mechanical properties of the soil and engineering stability.