-

Phenolic Moulding Compound BH4330-2 Sheet

BH4330-2 Phenolic Glass Fiber Moulding Compound for Electrical Insulation (High Strength Fixed Length Fibers) Usage: Suitable for insulating structural parts under the conditions of stable structural dimensions and high mechanical strength, and suitable for use in humid environments, and can also be pressed and wound tubes and cylinders. -

PMC Insulating Compression-Molded Parts

They feature high mechanical strength and heat resistance, excellent electrical insulation properties, low water absorption, low thermal conductivity, and high chemical resistance. Suitable for operation within a temperature range of -196°C to +200°C. -

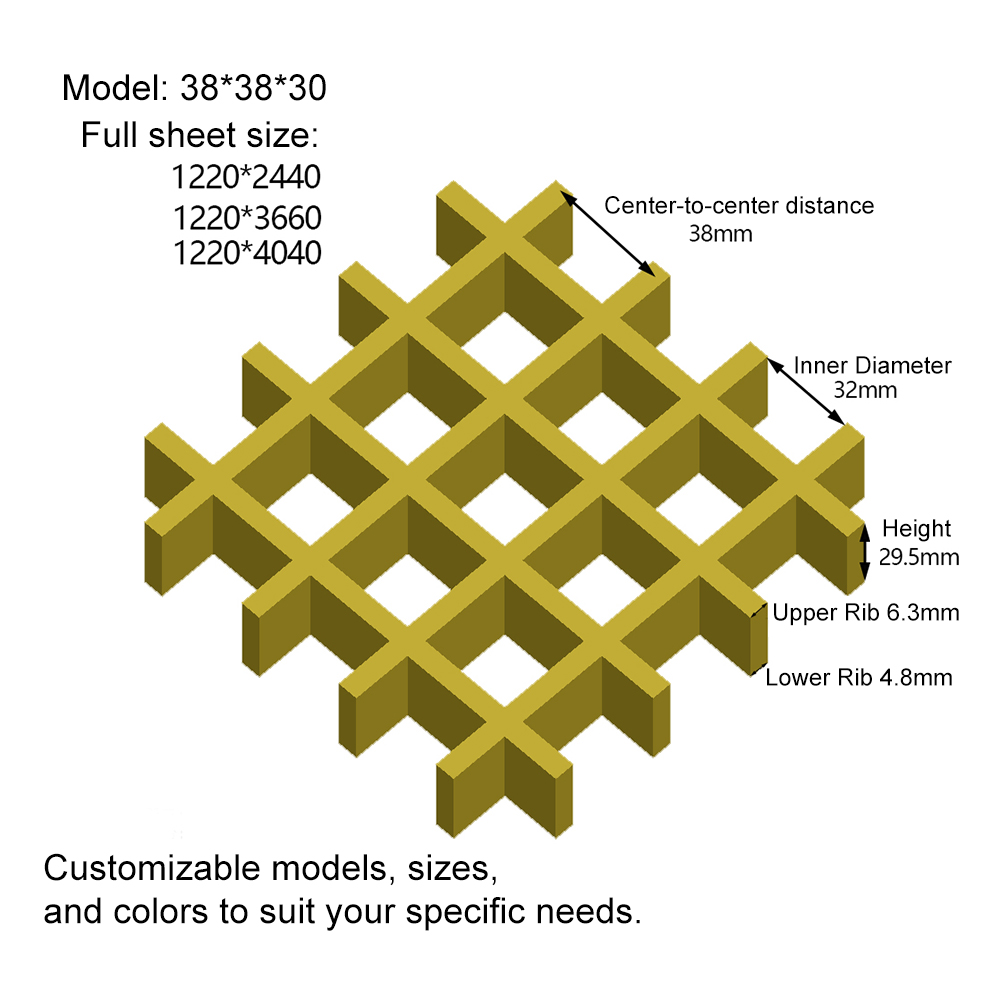

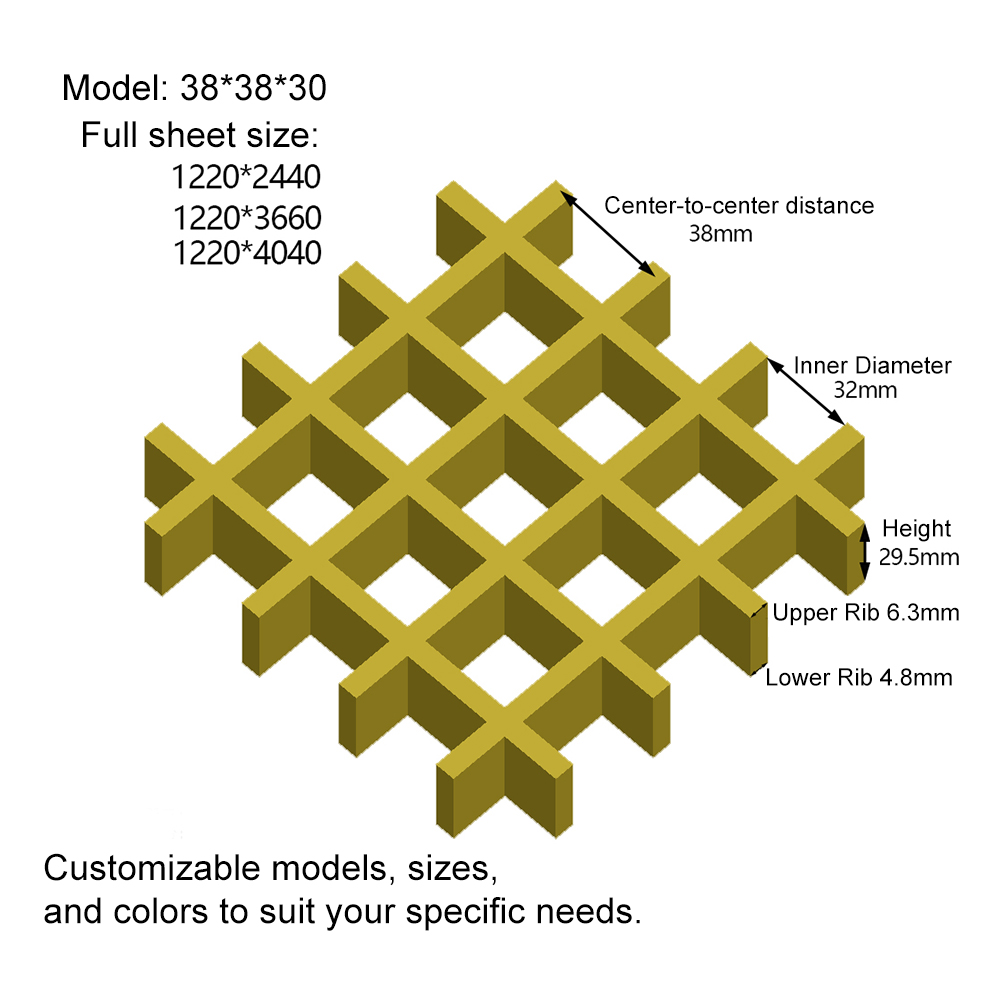

Pultruded FRP Grating

Pultruded fiberglass grating is manufactured using the pultrusion process. This technique involves continuously pulling a mixture of glass fibers and resin through a heated mold, forming profiles with high structural consistency and durability. This continuous production method ensures product uniformity and high quality. Compared to traditional manufacturing techniques, it allows for more precise control over fiber content and resin ratio, thereby optimizing the mechanical properties of the final product. -

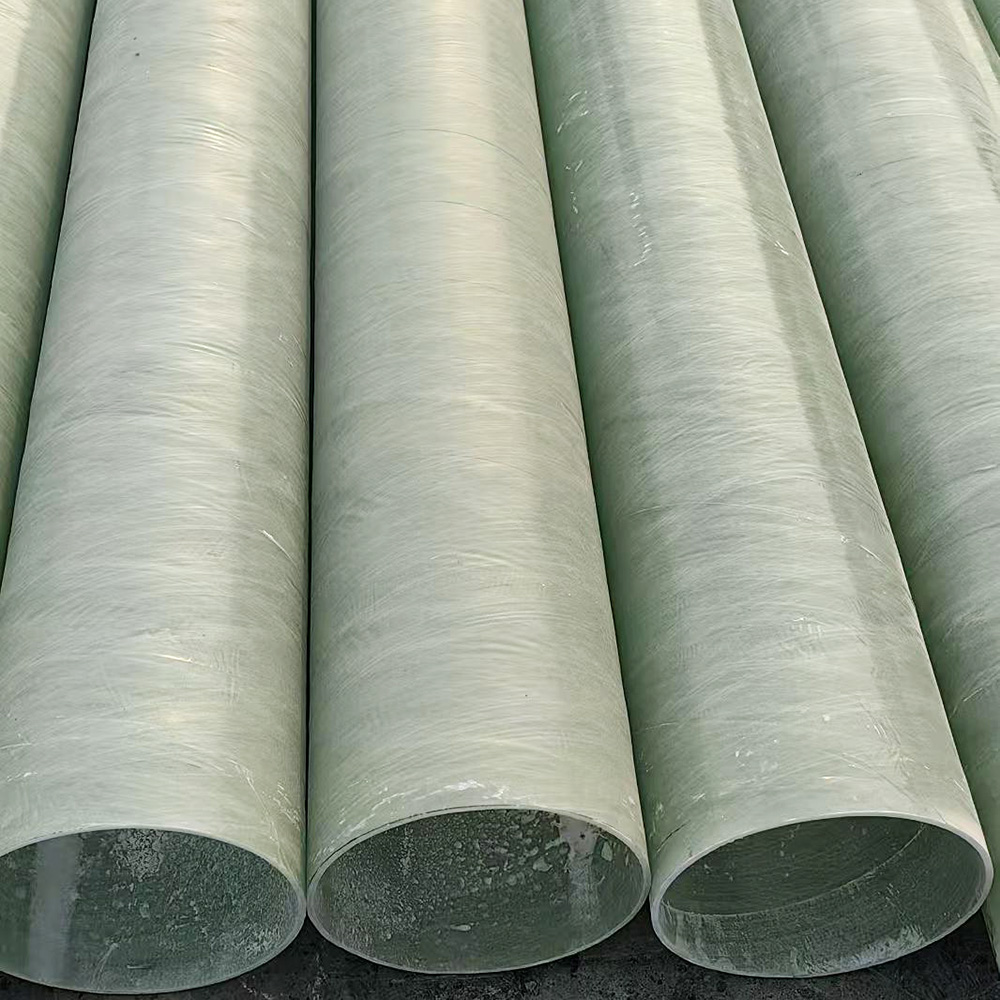

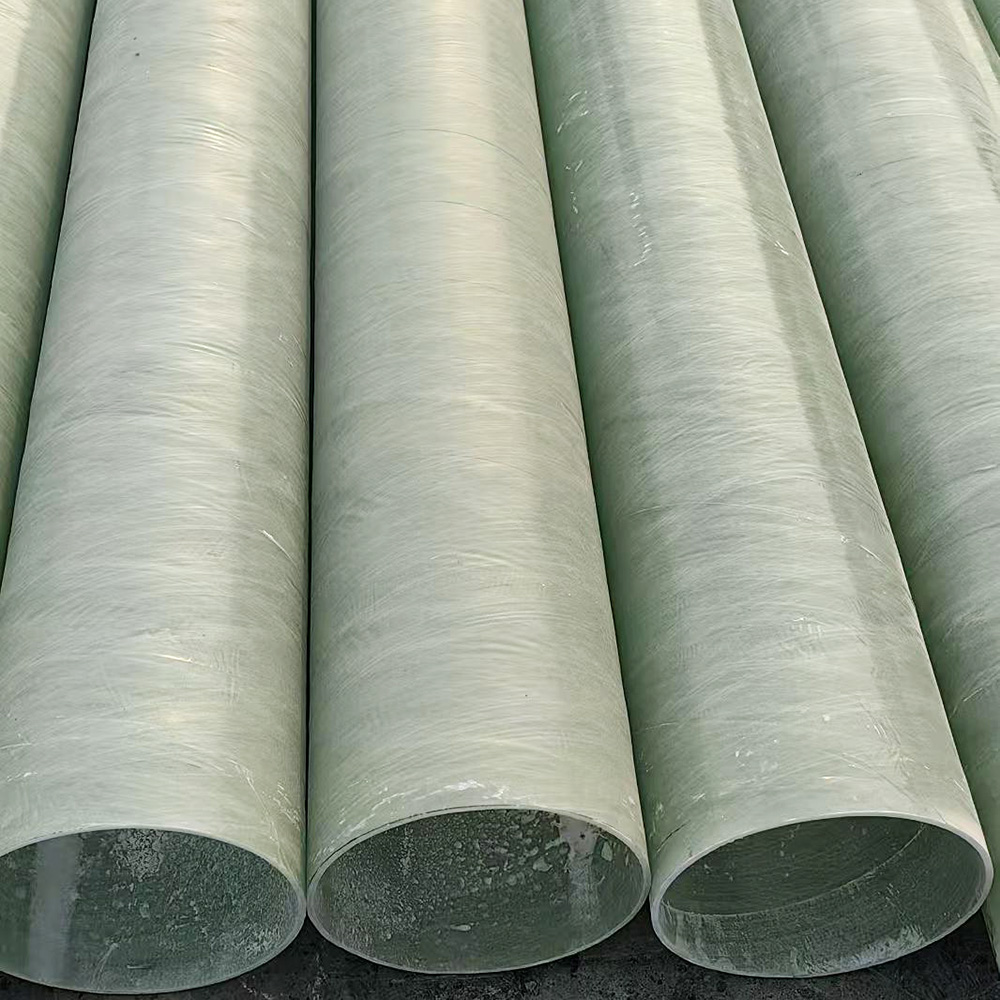

FRP Epoxy Pipe

FRP epoxy pipe is formally known as Glass Fiber Reinforced Epoxy (GRE) pipe. It is a high-performance composite material piping, manufactured using a filament winding or similar process, with high-strength glass fibers as the reinforcing material and epoxy resin as the matrix. Its core advantages include outstanding corrosion resistance (eliminating the need for protective coatings), light weight combined with high strength (simplifying installation and transport), extremely low thermal conductivity (providing thermal insulation and energy savings), and a smooth, non-scaling inner wall. These qualities make it an ideal replacement for traditional piping in sectors such as petroleum, chemical, marine engineering, electrical insulation, and water treatment. -

FRP Dampers

An FRP damper is a ventilation control product designed specifically for corrosive environments. Unlike traditional metal dampers, it is made from Fiberglass Reinforced Plastic (FRP), a material that perfectly combines the strength of fiberglass with the corrosion resistance of resin. This makes it an outstanding choice for handling air or flue gas containing corrosive chemical agents like acids, alkalis, and salts. -

FRP Flange

FRP (Fiberglass Reinforced Plastic) flanges are ring-shaped connectors used to join pipes, valves, pumps, or other equipment to create a complete piping system. They are made from a composite material consisting of glass fibers as the reinforcing material and synthetic resin as the matrix. -

Fiberglass Reinforced Plastic (FRP) Winding Process Pipe

FRP pipe is a lightweight, high-strength, corrosion-resistant non-metallic pipe. It is the glass fiber with resin matrix wound layer by layer onto the rotating core mold according to the process requirements. The wall structure is reasonable and advanced, which can give full play to the role of the material and improve the rigidity under the premise of meeting the use of strength to ensure the stability and reliability of the product. -

Press material FX501 extruded

FX501 phenolic glass fiber molded plastic use: It is suitable for pressing insulating structural parts with high mechanical strength, complex structure, large thin-walled, anticorrosive and moisture-resistant. -

Bulk Phenolic Fiberglass Molding Compound

This material is made of improved phenolic resin impregnated with alkali-free glass yarn, suitable for use as raw material for thermoforming products. The products have high mechanical strength, good insulating properties, corrosion resistance, moisture resistance, mildew resistance, lightweight components and other characteristics, suitable for pressing the requirements of high-strength mechanical components, complex shape of the electrical components, radio parts, high strength mechanical and electrical parts and rectifier (commutator), etc., and its products also have good electrical properties, especially for hot and humid zones. -

Phenolic Reinforced Molding Compound BH4330-3 Filament

BH4330-3, the product is mainly used for molding, power generation, railroads, aviation, and other dual-use industries, such as mechanical parts, with high mechanical strength, high insulation, high temperature, low temperature corrosion resistance and other characteristics. -

Press material AG-4V extruded BH4330-4 Blocks

Press material AG-4V extruded, diameter 50-52 mm., is made on the basis of modified phenol-formaldehyde resin as a binder and glass threads as a filler.

This material has high mechanical strength and heat resistance, good electrical insulating properties and low water absorption. AG-4V is chemically resistant and can be used for the manufacture of products used in tropical climates. -

Moulding material (Press material) DSV-2O BH4330-5

DSV press material is a type of glass-filled press materials made in the form of granules on the basis of complex glass filaments and refer to dosed glass fibers impregnated with a modified phenol-formaldehyde binder.

Main advantages: high mechanical properties, fluidity, high heat resistance.