Industry News

-

The customer uses the powder chopped strand mat 300g/m2 (fiberglass chopped strand mat) produced by our company to make transparent tiles

Product Code # CSMEP300 Product Name Chopped Strand Mat Product Description E-glass,Powder,300g/m2. TECHNICAL DATA SHEETS Item Unit Standard Density g/sqm 300±20 Binder Content % 4.5±1 Moisture % ≤0.2 Fiber Length mm 50 Roll Width mm 150 — 2600 Normal Roll Width mm 1040 / 1...Read more -

Helping Southeast Asian customers to ship 1 container (17600kgs) of unsaturated polyester resin before the National Day holiday (2022-9-30)

Description: DS- 126PN- 1 is an orthophthalic type promoted unsaturated polyester resin with low viscosity and medium reactivity. The resin has good impregnates of glass fiber reinforcement and is particularly applicable to the products like glass tiles and transparent items. Features: Excellent ...Read more -

Popular science: How important is rhodium powder, which is 10 times more expensive than gold, in the glass fiber industry?

Rhodium, commonly known as “black gold”, is the platinum group metal with the least amount of resources and production. The content of rhodium in the earth’s crust is only one billionth of a billionth. As the saying goes, “what is rare is precious”, in terms of value...Read more -

Characteristics, advantages and application fields of fiberglass chopped

Fiberglass is an inorganic non-metallic material, which is made from pyrophyllite, quartz sand, kaolin, etc., through high temperature melting, wire drawing, drying, winding and reprocessing of the original yarn. , heat insulation, sound insulation, high tensile strength, good electrical insulati...Read more -

Hollow glass microspheres used in paint coatings

Glass beads have the smallest specific surface area and low oil absorption rate, which can greatly reduce the use of other production components in the coating. The surface of the glass bead vitrified is more resistant to chemical corrosion and has a reflective effect on light. Therefore, the pai...Read more -

What is the difference between ground glass fiber powder and glass fiber chopped strands

In the market, many people do not know much about ground glass fiber powder and glass fiber chopped strands, and they are often confused. Today we will introduce the difference between them: Grinding glass fiber powder is to pulverize glass fiber filaments (leftovers) into different lengths (mes...Read more -

What is fiberglass yarn? Properties and uses of fiberglass yarn

Fiberglass yarn is made of glass balls or waste glass through high temperature melting, wire drawing, winding, weaving and other processes. Fiberglass yarn is mainly used as electrical insulating material, industrial filter material, anti-corrosion, moisture-proof, heat-insulating, sound-insulati...Read more -

Application comparison of vinyl resin and epoxy resin

1. Application fields of vinyl resin By industry, the global vinyl resin market is largely classified into three categories: composites, paints, coatings, and others. Vinyl resin matrix composites are widely used in pipelines, storage tanks, construction, transportation and other industries. Viny...Read more -

The use of fiberglass cloth

1. Fiberglass cloth is usually used as a reinforcing material in composite materials, electrical insulating materials and thermal insulation materials, circuit substrates and other fields of the national economy. 2. Fiberglass cloth is mostly used in the hand lay-up process. Fiberglass cloth is ...Read more -

What fields are the performance characteristics of FRP sand-filled pipes mainly used in?

What fields are the performance characteristics of FRP sand-filled pipes mainly used in? Scope of application: 1. Municipal drainage and sewage pipeline system engineering. 2. Buried drainage and sewage in apartments and residential quarters. 3. Pre-buried pipelines of expressways, underground wa...Read more -

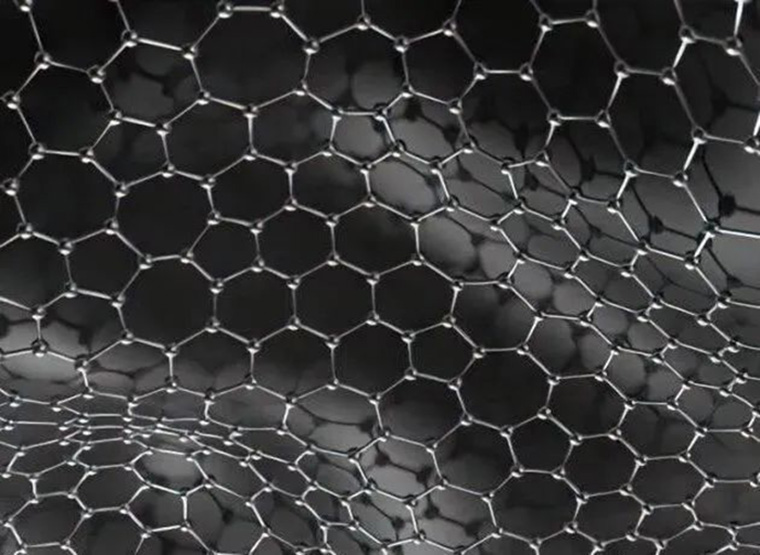

【Composite information】Super strong graphene reinforced plastic

Graphene enhances the properties of plastics while reducing raw material usage by 30 percent. Gerdau Graphene, a nanotechnology company that provides advanced graphene-enhanced materials for industrial applications, announced that it has created next-generation graphene-enhanced plastics for pol...Read more -

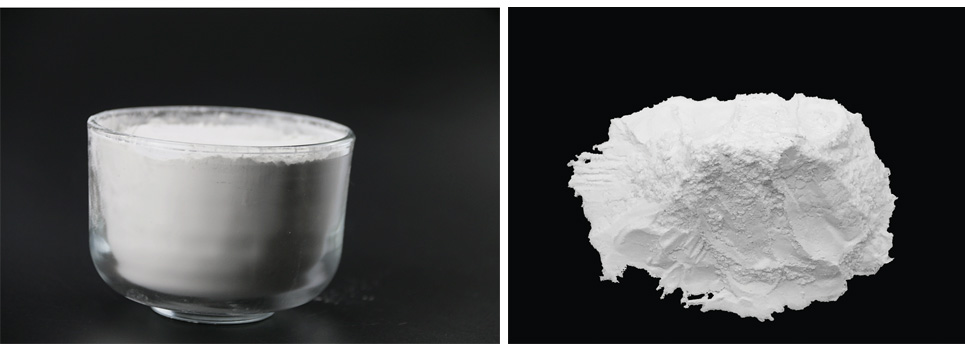

What are the technical requirements of fiberglass powder for the use of fiberglass powder

1. What is fiberglass powder Fiberglass powder, also known as fiberglass powder, is a powder obtained by cutting, grinding and sieving specially drawn continuous fiberglass strands. White or off-white. 2. What are the uses of fiberglass powder The main uses of fiberglass powder are: As a fillin...Read more