FRP lining is a common and most important corrosion control method in heavy-duty anti-corrosion construction. Among them, hand lay-up FRP is widely used because of its simple operation, convenience and flexibility. It can be said that hand lay-up method accounts for more than 80% of FRP anti-corrosion construction. proportion. The “three major materials” resin, fiber and powder fiber in hand-laid FRP are the skeleton of FRP, supporting the strength of the FRP system, and are an important part of realizing the long-term effect of anti-corrosion of FRP.

According to the difference of corrosive environment and medium, the constituent materials of FRP will also change. Conditional material selection during construction is a key factor to ensure that the finished FRP product can adapt to the corrosive environment and its durability. Therefore, the selection of FRP reinforcement materials must be determined before construction. For example, reinforcement materials represented by glass fiber are the most common fiber materials, which can resist most acid corrosion; however, they are not resistant to hydrofluoric acid and hot phosphoric acid corrosion. Use polyester, polypropylene and other organic fiber cloth and felt, you can also choose to use linen or degreased gauze, and some FRP products need corrosion resistance and conductivity, you can choose carbon fiber materials. In a word, the selection of hand lay-up FRP reinforced fiber is a skill and knowledge point that anti-corrosion technology and designers must master.

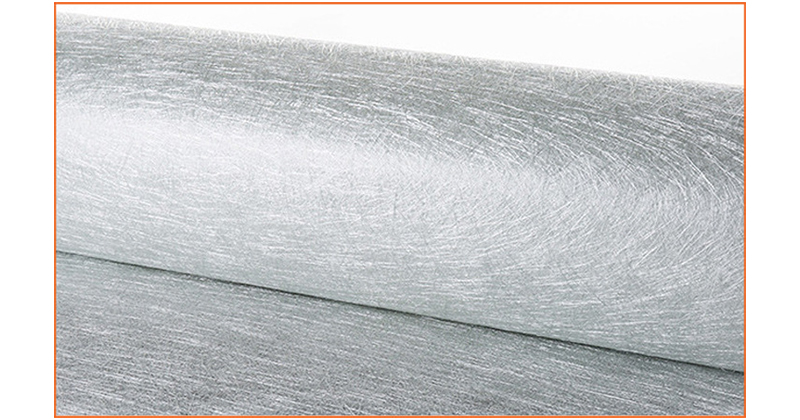

In the pasted FRP products, most of the reinforcing fibers are glass fibers, whether it is cloth, felt or yarn. The main reason is that in addition to the price factor, it also has the following excellent characteristics:

01 Chemical resistance

Inorganic fiberglass textile fibers will not rot, mold or deteriorate. They are resistant to most acids except hydrofluoric and hot phosphoric acid.

02 Dimensionally stable

Glass fiber yarns used to make glass fabrics do not stretch or shrink due to changes in atmospheric conditions. The nominal elongation at break is 3-4%. The average linear thermal expansion coefficient of bulk E-glass is 5.4 × 10-6 cm/cm/°C.

03 Good thermal performance

Fiberglass fabrics have a lower coefficient of thermal expansion and higher thermal conductivity. Fiberglass dissipates heat faster than asbestos or organic fibers.

04 High tensile strength

Fiberglass yarn has a high strength-to-weight ratio. A pound of fiberglass yarn is twice as strong as steel wire. The ability to engineer unidirectional or bidirectional strength into the fabric greatly increases the flexibility of end-use products.

05 High heat resistance

Inorganic glass fibers do not burn and are essentially immune to the high bake and cure temperatures often encountered in industrial processing. Fiberglass will retain about 50% of its strength at 700°F and 25% at 1000°F.

06 Low hygroscopicity

Fiberglass yarns are made of non-porous fibers and therefore have very low moisture absorption.

07 Good electrical insulation

High dielectric strength and relatively low dielectric constant, along with low water absorption and high temperature resistance, make fiberglass fabrics excellent for electrical insulation.

08 Product flexibility

The very fine filaments used in fiberglass yarns, a variety of yarn sizes and configurations, different weave types, and many special finishes make fiberglass fabrics useful for a wide range of industrial end uses.

09 low cost low price

Fiberglass fabrics can do the job and are comparable in cost to synthetic and natural fiber fabrics.

Therefore, glass fiber is an ideal hand lay-up FRP reinforcement material, which is economical, inexpensive, and easy to operate. It is one of the most widely used materials among many reinforcement materials at present.

Post time: Oct-21-2022