Manufacturer for Pultrusion Roving - E-glass Assembled Roving For Spray up – Beihai Fiberglass

Manufacturer for Pultrusion Roving - E-glass Assembled Roving For Spray up – Beihai Fiberglass Detail:

E-glass Assembled Roving For Spray up

Assembled Roving for spray-up is compatible with UP and VE resins. It delivers properties of low static, excellent dispersion, and good wet out in resins.

Features

●Low static

●Excellent dispersion

●Good wet-out in resins

Application

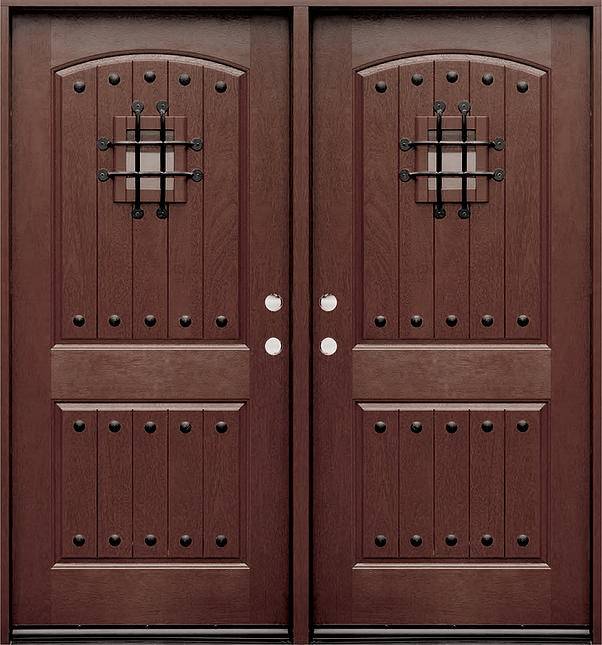

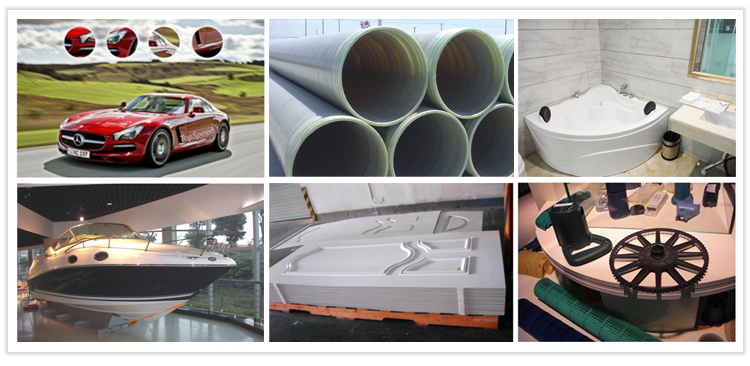

It covers a wide range of applications: bathtub, FRP boat hulls, various pipes, storage vessels and cooling towers.

Product List

|

Item |

Linear Density |

Resin Compatibility |

Features |

End Use |

|

BHSU-01A |

2400, 4800 |

UP, VE |

fast wet out, easy roll-out, optimum dispersion |

bathtub, supporting components |

|

BHSU-02A |

2400, 4800 |

UP, VE |

easy roll-out, no spring-back |

bathroom equipment, yacht components |

|

BHSU-03A |

2400, 4800 |

UP, VE, PU |

fast wet out, excellent mechanical and water resistance property |

bathtub, FRP boat hull |

|

BHSU-04A |

2400, 4800 |

UP, VE |

moderate wet out speed |

swimming pool, bathtub |

| Identification | |

| Type of Glass |

E |

| Assembled Roving |

R |

| Filament Diameter, μm |

11, 12, 13 |

| Linear Density, tex |

2400, 3000 |

| Technical Parameters | |||

|

Linear Density (%) |

Moisture Content (%) |

Size Content (%) |

Stiffness (mm) |

|

ISO 1889 |

ISO 3344 |

ISO 1887 |

ISO 3375 |

|

±5 |

≤0.10 |

1.05±0.15 |

135±20 |

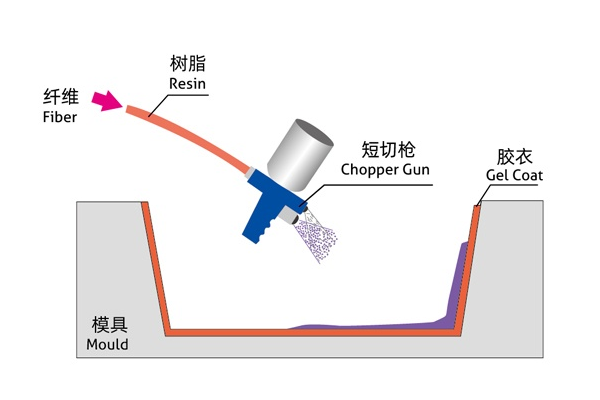

Spray-up Process

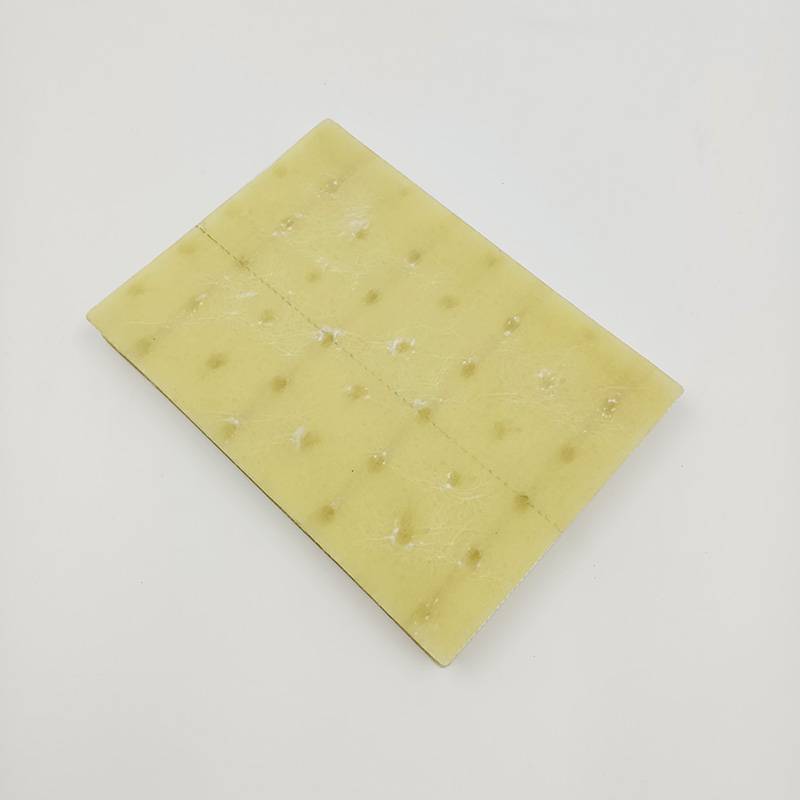

A mould is sprayed with a mixture of catalyzed resin and chopped fiberglass roving ( fiberglass cut to specific length using a chopper gun ) . Then the glass-resin mixture is well compacted , usually manually , for complete impregnation and deairing . After curing the finished composite part is de-molded

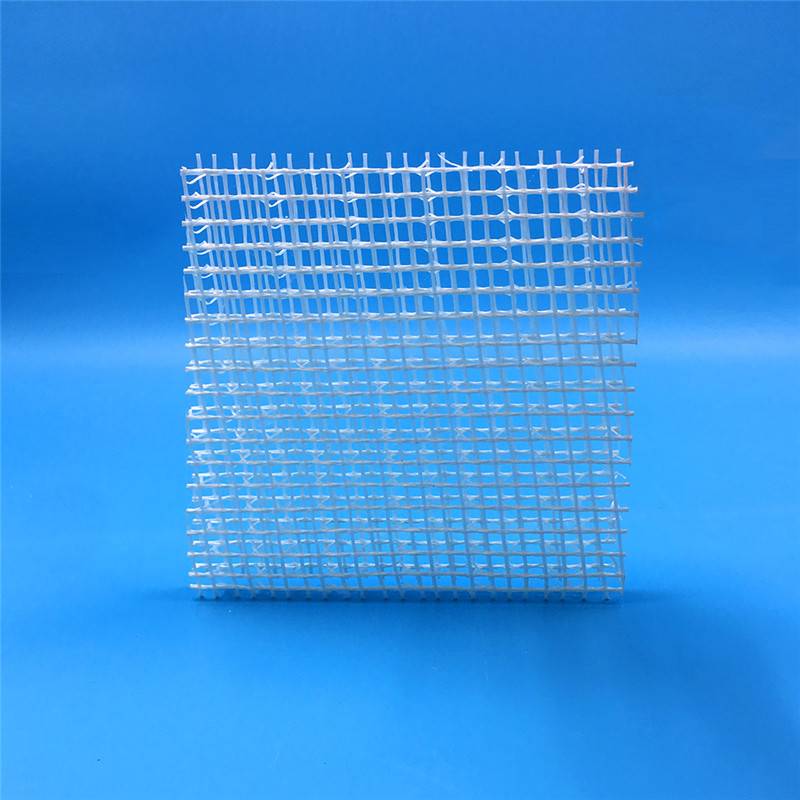

Product detail pictures:

Related Product Guide:

With our leading technology also as our spirit of innovation,mutual cooperation, benefits and advancement, we'll build a prosperous future together with your esteemed organization for Manufacturer for Pultrusion Roving - E-glass Assembled Roving For Spray up – Beihai Fiberglass , The product will supply to all over the world, such as: Australia, America, Curacao, Our factory covers an area of 12,000 square meters, and has a staff of 200 people, among which there are 5 technical executives. We are specialized in producing.We have rich experience in export. Welcome to contact us and your enquiry will be replied as soon as possible.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!