High Quality for Fiberglass Smc Roving For Car Body Using - E-glass Assembled Roving For Filament Winding – Beihai Fiberglass

High Quality for Fiberglass Smc Roving For Car Body Using - E-glass Assembled Roving For Filament Winding – Beihai Fiberglass Detail:

E-glass Assembled Roving For Filament Winding

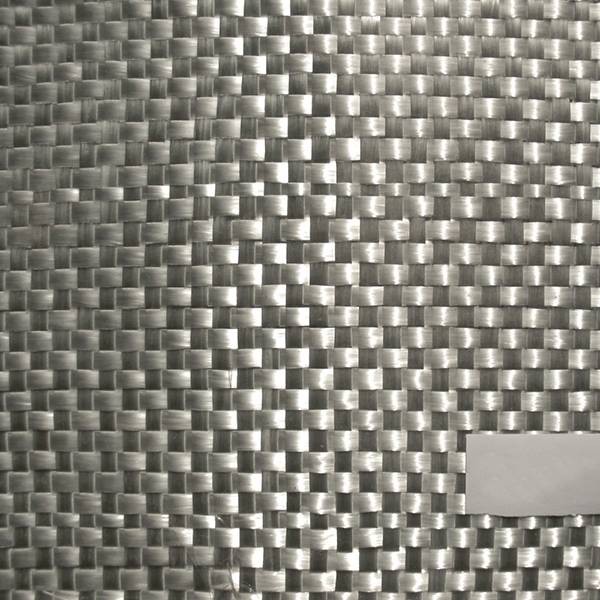

Assembled Roving for Filament Winding is specially designed for FRP filament winding process, compatible with unsaturated polyester.

Its final composite product delivers excellent mechanical property.

Features

●Excellent mechanical property

●Fast wet out in resins

●Low fuzz

Application

It is mainly used to manufacture storage vessels and pipes in petroleum, chemical and mining industries.

Product List

|

Item |

Linear Density |

Resin Compatibility |

Features |

End Use |

|

BHFW-01A |

2400, 4800 |

UP |

fast wet out, low fuzz, high strength |

pipeline |

| Identification | |

| Type of Glass |

E |

| Assembled Roving |

R |

| Filament Diameter, μm |

13 |

| Linear Density, tex |

2400, 4800 |

| Technical Parameters | |||

|

Linear Density (%) |

Moisture Content (%) |

Size Content (%) |

Breakage Strength (N/tex) |

|

ISO 1889 |

ISO 3344 |

ISO 1887 |

ISO 3341 |

|

±6 |

≤0.10 |

0.55±0.15 |

≥0.40 |

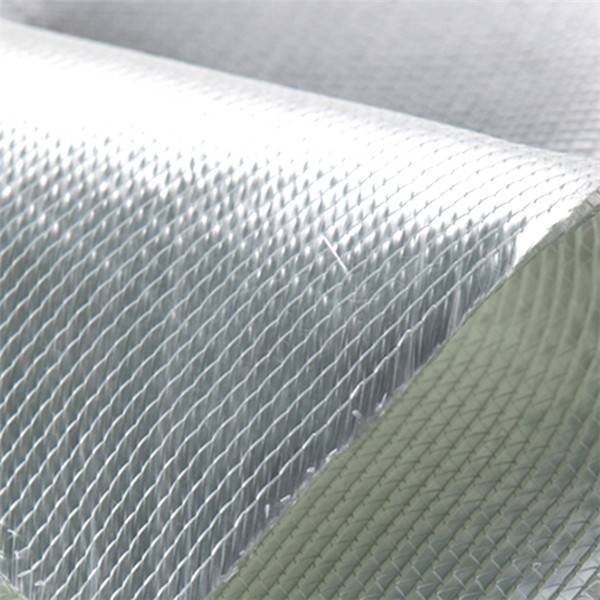

Filament Winding Process

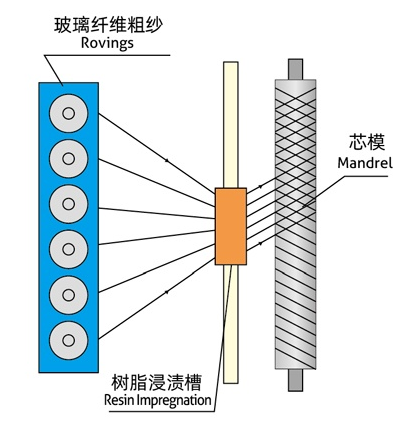

Traditional Filament Winding

In the filament winding process , continuous strands of resin-impregnated glassfiber are wound under tension onto a mandrel in precise geometric patterns tobuild up the part which is then cured to form the finished parts.

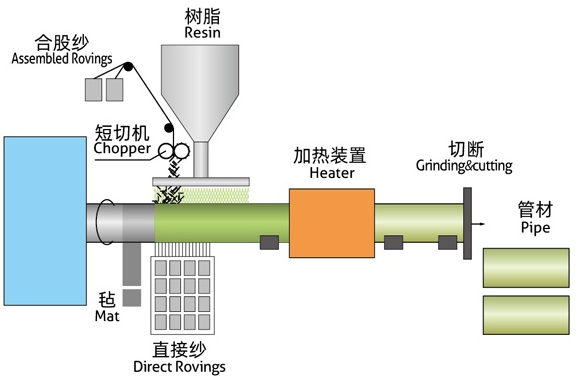

Continuous Filament Winding

Multiple laminate layers , composed of resin , reinforcement glass and other materials are applied to a rotating mandrel , which is formed from a continuous steel band continuously traveling in a cork-screw motion . The composite part is heated and cured in place as the mandrel travels through the line and then cut into a specific length with a traveling cut-off saw .

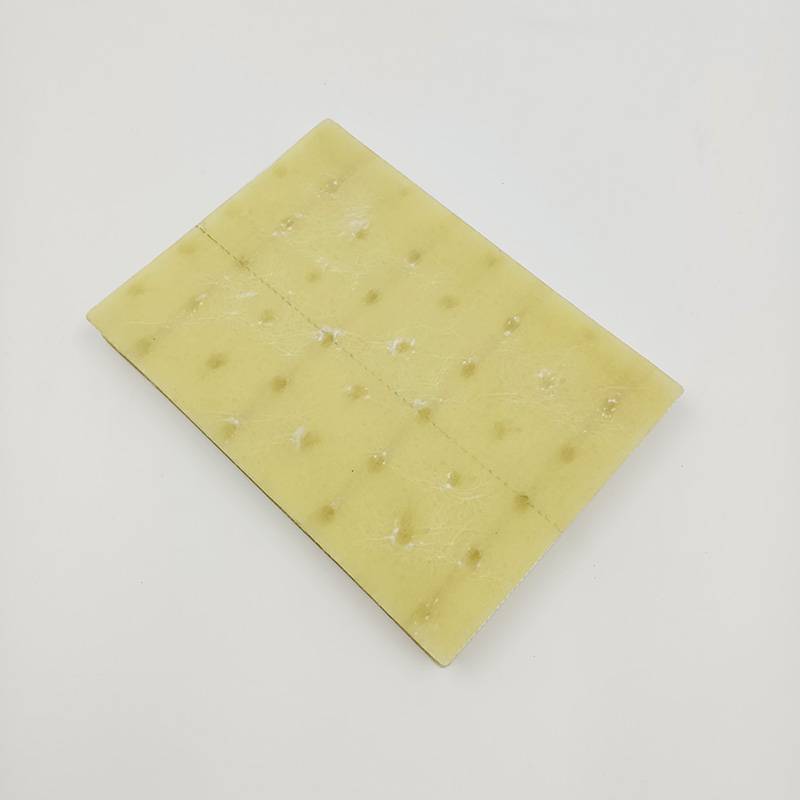

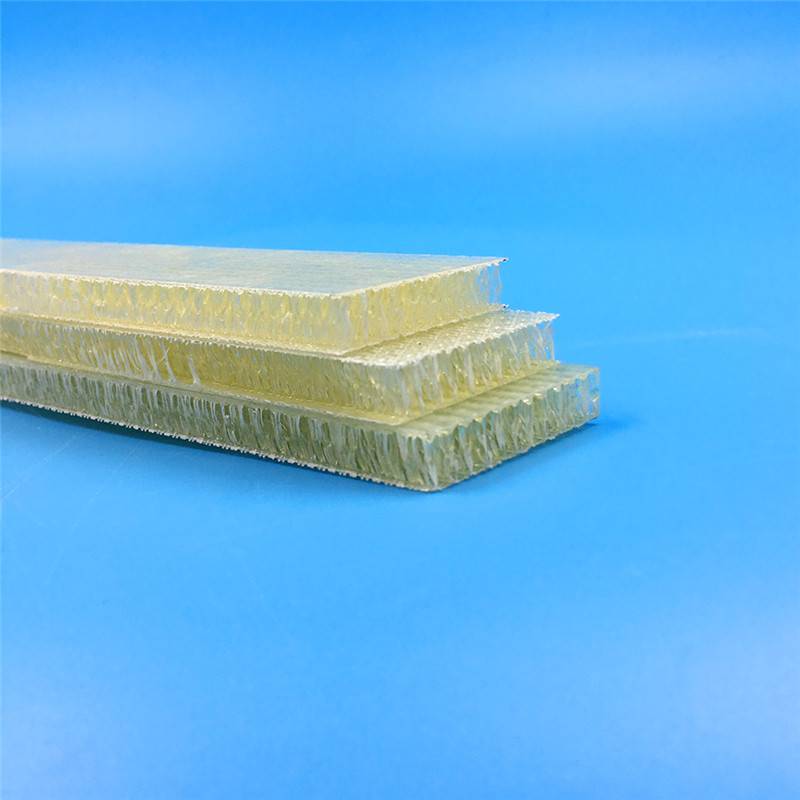

Product detail pictures:

Related Product Guide:

We keep on with the theory of "quality first, provider initially, constant improvement and innovation to meet the customers" with the management and "zero defect, zero complaints" as the standard objective. To great our company, we deliver the merchandise using the fantastic excellent at the reasonable price for High Quality for Fiberglass Smc Roving For Car Body Using - E-glass Assembled Roving For Filament Winding – Beihai Fiberglass , The product will supply to all over the world, such as: Jamaica, Lisbon, Nepal, We have gained a lot of recognition among customers spread all across the world. They trust us and always give repetitive orders. Furthermore, mentioned below are some of the major factors that have played significant role in our tremendous growth in this domain.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!