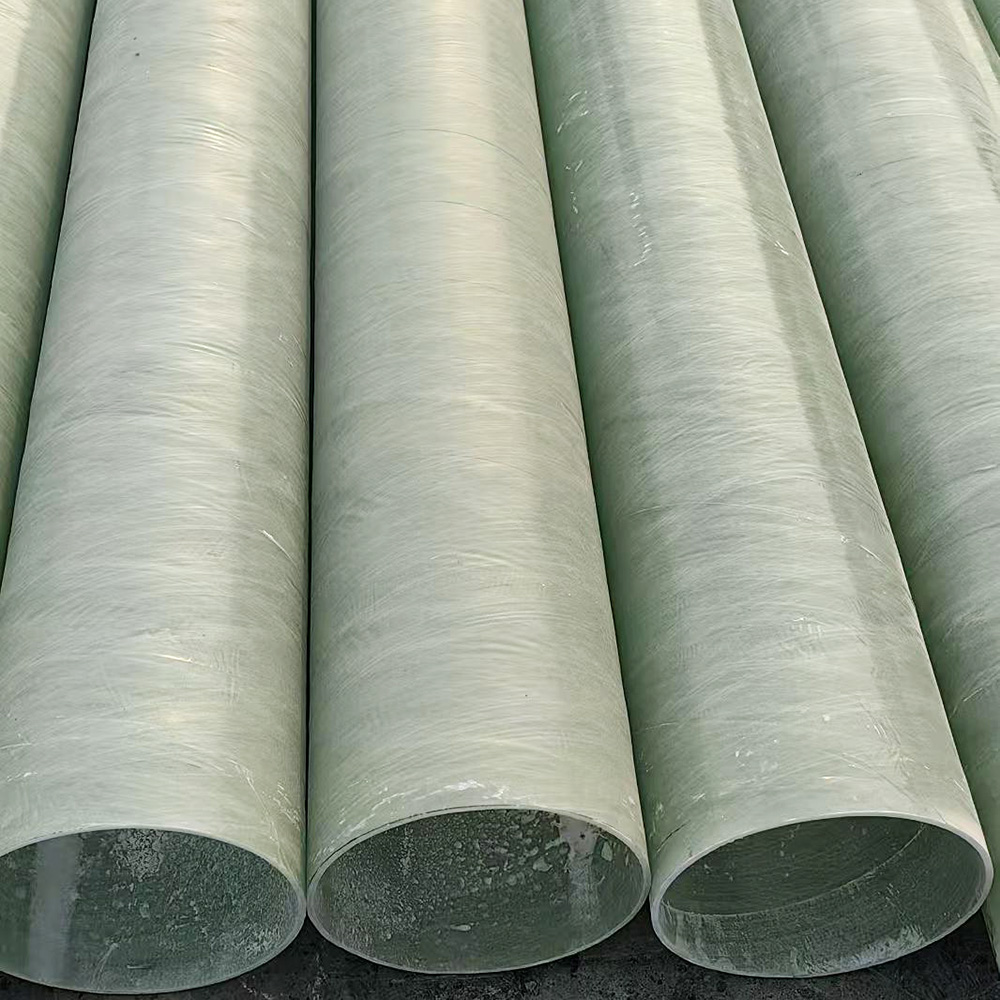

Fiberglass Reinforced Plastic (FRP) Winding Process Pipe

Product Introduction

FRP pipe is a lightweight, high-strength, corrosion-resistant non-metallic pipe. It is the fiberglass with resin matrix wound layer by layer onto the rotating core mold according to the process requirements. The wall structure is reasonable and advanced, which can give full play to the role of the material and improve the rigidity under the premise of meeting the use of strength to ensure the stability and reliability of the product. FRP with its excellent chemical corrosion resistance, lightweight and high strength, non-scaling, seismic, and ordinary pipe and cast iron pipe compared with the use of long life, low overall cost, fast installation, safety and reliability, etc., accepted by the user. FRP pipe applications involve petroleum, chemical, water supply and drainage industries.

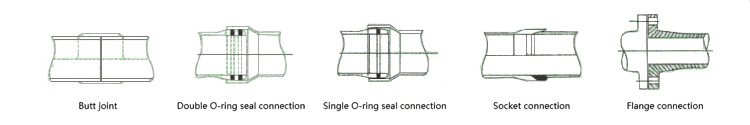

Connection of FRP Pipe

1. FRP pipe commonly used connection method has five kinds.

Wrapped butt, take on the rubber connection, flange connection and socket coupling (with rubber ring sealing socket connection) the first three methods are mostly used for fixed connection between the pipe and the pipe, flange connection is used for frequently disassembled parts, and socket coupling is mostly used for the connection between the underground pipeline. (See figure below).

Wrap butt method is suitable for large-diameter pipe bending parts of the connection and on-site repair, to undertake the rubber connection method is suitable for fixed-length pipe connection (but there is a corrosion-resistant layer of pipe can not be used) pipes and pumps to connect, due to vibration, the application of flexible joints in order to reduce the deformation of the pipeline and fittings parts.

2. Pipe accessories

Fiberglass reinforced plastic pipe accessories are elbow, tee, flange-type joints, T-type joints, reducers, etc., all kinds of fiberglass reinforced plastic pipes have corresponding accessories to match see the following chart.

Fiberglass Reinforced Plastic (FRP) Winding Process Pipe

Main Molding Process:

Controlled by computer, the inner lining layer is made and defoamed according to the requirements; after the inner lining layer is gelatinized, the structural layer is wound according to the designed line shape and thickness; finally, the outer protective layer is laid; if requested by the users, flame retardant, ultraviolet ray protection agent and other special functional additives or fillers can be added.

Main raw and auxiliary materials:

Resin, glass fiber mat, continuous glass fiber, etc.

Product Specification:

We can provide users with winding pipes with diameters from 10mm to 4000mm and lengths of 6m, 10m and 12m with elbows, tees, flanges, Y-type and T-type joints and pipe fittings for reducers.

Execution standard and inspection:

Execution of “JC/T552-2011 fiber winding reinforced thermosetting resin pressure pipe” standard.

Inspection of lining layer: degree of curing, dry spots or bubbles, uniform state of anti-corrosion layer.

Inspection of structural layer: degree of curing, any damaging or structural fracture.

Full inspection: Bartholomew’s hardness, wall thickness, diameter, length, hydraulic pressure test.

Product Applications