Excellent quality Continuous Roving Fiberglass - E-glass Assembled Roving For Filament Winding – Beihai Fiberglass

Excellent quality Continuous Roving Fiberglass - E-glass Assembled Roving For Filament Winding – Beihai Fiberglass Detail:

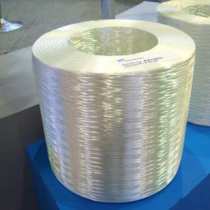

E-glass Assembled Roving For Filament Winding

Assembled Roving for Filament Winding is specially designed for FRP filament winding process, compatible with unsaturated polyester.

Its final composite product delivers excellent mechanical property.

Features

●Excellent mechanical property

●Fast wet out in resins

●Low fuzz

Application

It is mainly used to manufacture storage vessels and pipes in petroleum, chemical and mining industries.

Product List

|

Item |

Linear Density |

Resin Compatibility |

Features |

End Use |

|

BHFW-01A |

2400, 4800 |

UP |

fast wet out, low fuzz, high strength |

pipeline |

| Identification | |

| Type of Glass |

E |

| Assembled Roving |

R |

| Filament Diameter, μm |

13 |

| Linear Density, tex |

2400, 4800 |

| Technical Parameters | |||

|

Linear Density (%) |

Moisture Content (%) |

Size Content (%) |

Breakage Strength (N/tex) |

|

ISO 1889 |

ISO 3344 |

ISO 1887 |

ISO 3341 |

|

±6 |

≤0.10 |

0.55±0.15 |

≥0.40 |

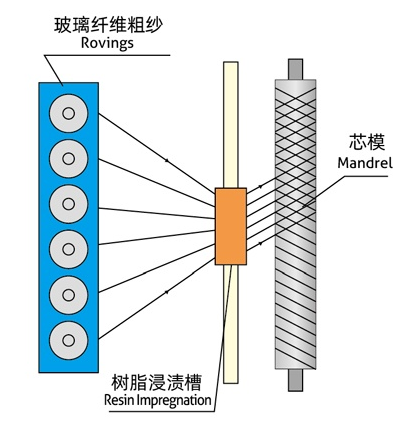

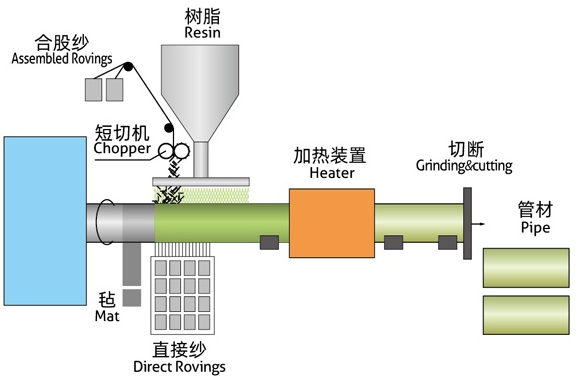

Filament Winding Process

Traditional Filament Winding

In the filament winding process , continuous strands of resin-impregnated glassfiber are wound under tension onto a mandrel in precise geometric patterns tobuild up the part which is then cured to form the finished parts.

Continuous Filament Winding

Multiple laminate layers , composed of resin , reinforcement glass and other materials are applied to a rotating mandrel , which is formed from a continuous steel band continuously traveling in a cork-screw motion . The composite part is heated and cured in place as the mandrel travels through the line and then cut into a specific length with a traveling cut-off saw .

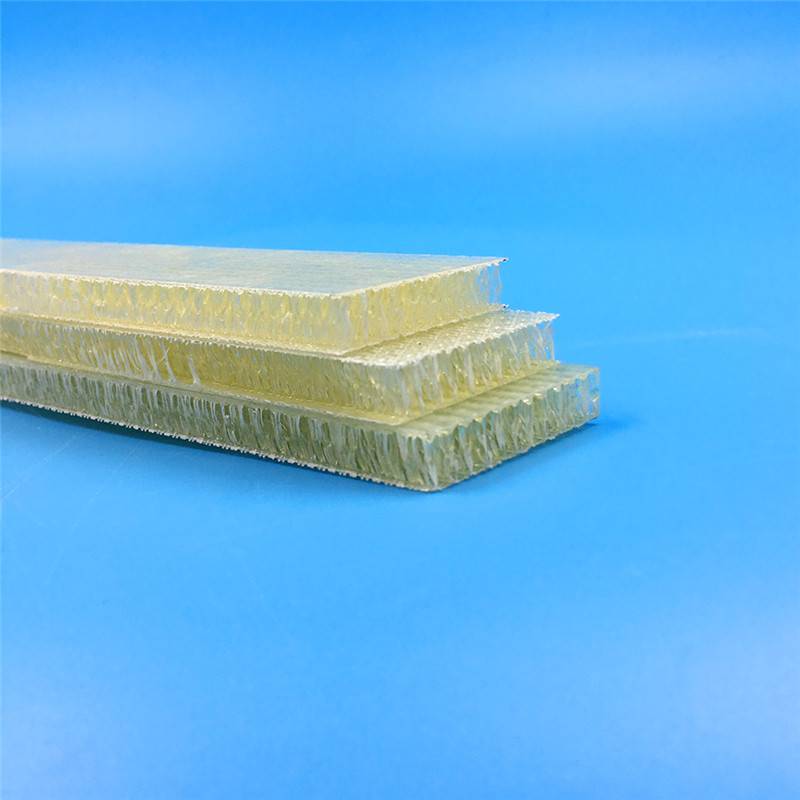

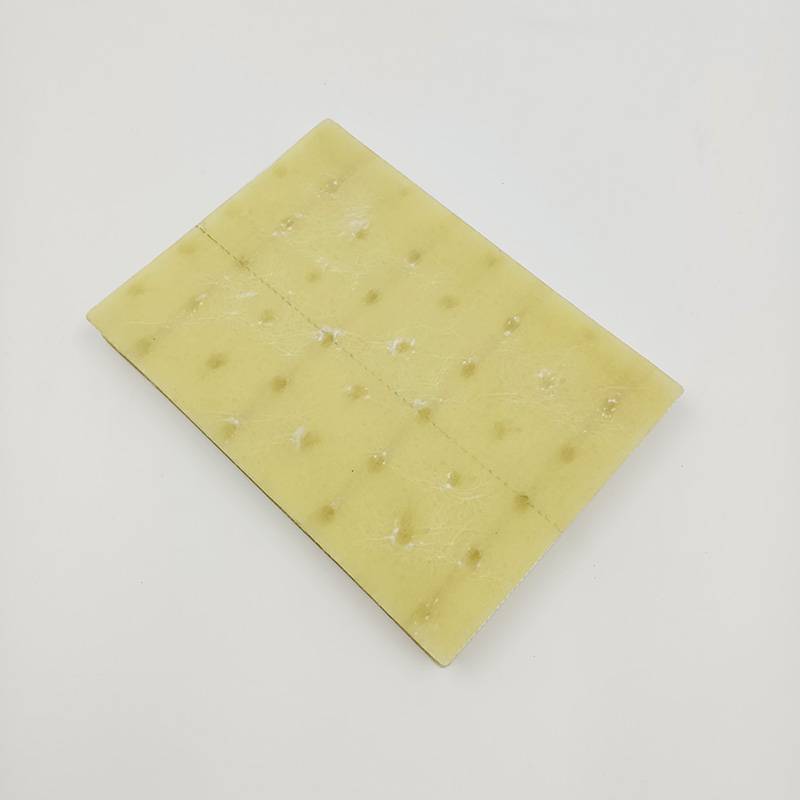

Product detail pictures:

Related Product Guide:

We've numerous great employees customers excellent at promoting, QC, and working with kinds of troublesome difficulty inside the generation method for Excellent quality Continuous Roving Fiberglass - E-glass Assembled Roving For Filament Winding – Beihai Fiberglass , The product will supply to all over the world, such as: Bahrain, Malta, Cannes, Due to our strict pursues in quality, and after-sale service, our product gets more and more popular around the world. Many clients came to visit our factory and place orders. And there are also many foreign friends who came for sight seeing, or entrust us to buy other stuff for them. You are most welcome to come to China, to our city and to our factory!

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.