E Glass Multi Ends Centrifugal Casting Roving for manufacturing Pipes with Various Specifications

Assembled Roving for Centrifugal Casting is coated with silane-based sizing, compatible with UP resin, delivering excellent choppability and dispersion, low static , fast wet out, and excellent mechanical properties of the composite products.

Features

- Excellent static control and choppability

- Fast wet-out

- Low resin demand, allowing high filler loading for low cost

- Excellent mechanical property of the finished composite parts with resins

Application

Mainly used to produce HOBAS pipes of various specifications and can greatly enhance the strength of FRP pipes.

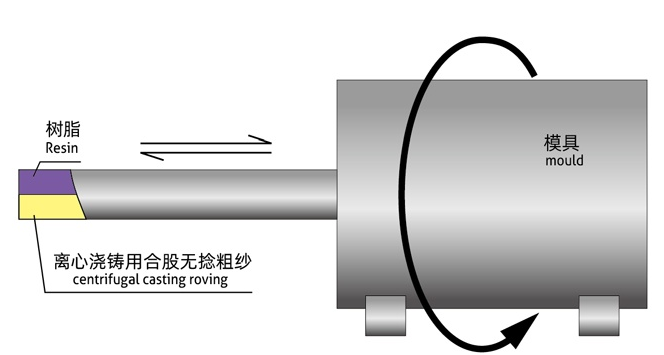

Centrifugal Casting Process

The raw materials , including resin , chopped reinforcement ( fiberglass ) , and filler , are fed into the interior of a rotating mould according to a specific proportion . Due to centrifugal force the materials are pressed against the wall of the mould under pressure , and the compound materials are compacted and deaired .After curing the composite part is removed from the mould

| Type of Glass |

E |

| Assembled Roving |

R |

| Filament Diameter, μm |

13 |

| Linear Density, tex |

2400 |

| Product Process |

Centrifugal Casting |

|

Technical Parameters |

|||

|

Linear Density (%) |

Moisture Content (%) |

Size Content (%) |

Stiffness (mm) |

|

ISO 1889 |

ISO 3344 |

ISO 1887 |

ISO 3375 |

|

±5 |

≤0.10 |

0.95±0.15 |

130±20 |