China Fiberglass Roving for Spray up/ Injection / Pipe / Panel /BMC/ SMC/ Pultrusion

Assembled Roving is designed for class A surface and structural SMC process. It is coated with a high performance compound sizing compatible with unsaturated polyester resin and vinyl ester resin.Except for normal specifications,Special specification can be customized.

Mainly used in the manufacture of auto parts and body parts, electric appliances and meter shells, the materials of building materials, water tank boards, sports equipment etc.

Product Features

◎ Fast and complete wet-out.

◎ Low static,no fuzz

◎ Excellent mechanical property

◎ Even tension,excellent chopped performance and dispersion,good flow ability under mold press.

◎Good wet-out

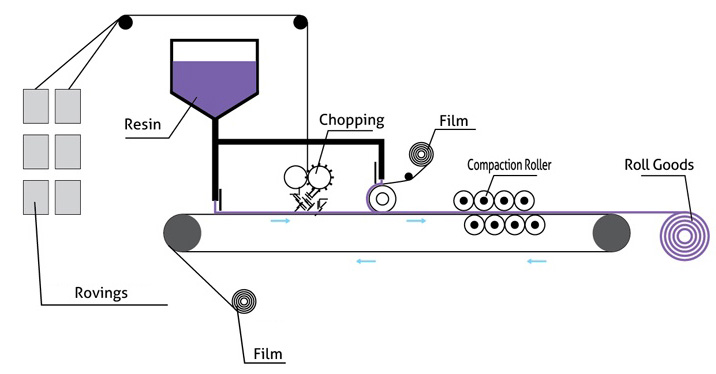

SMC Process

Mix the resins , fillers and other materials well to form a resin paste ,apply the paste on a first film , disperse chopped glass fibers evenly or the resin paste film and cover this paste film with another layer of resipaste film , and then compact the two paste films with pressure rollers of a SMC machine unit to form sheet molding compound products.

| Identification | |

| Type of Glass |

E |

| Assembled Roving |

R |

| Filament Diameter, μm |

13, 14 |

| Linear Density, tex |

2400, 4392 |

Technical Parameters

|

Linear Density (%) |

Moisture Content (%) |

Size Content (%) |

Breakage Strength (N/Tex) |

|

ISO1889 |

ISO3344 |

ISO1887 |

IS03375 |

|

±5 |

≤0.10 |

1.25±0.15 |

160±20 |

Storage

Unless otherwise specified, the fiberglass products should be in dry, cool and moisture-proof area. The room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65%. It is best if the price is used within 12 months after production date. The fiberglass products should remain in their original packaging until just prior to user.

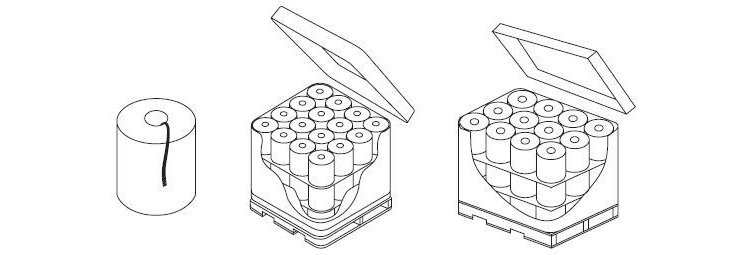

To ensure safety and avoid damage to the product, the pallets not be stacked more than three layers high. When the pallets are stacked in 2 or 3 layers, special care should be taken to correctly and smoothly move the top pallet.

Product Packing

E Glass Glass Fiber / Fiberglass SMC Roving For Water Tank TEX 4800 Each rolls is approximately 18KG, 48/64 rolls a tray, 48 rolls are 3 floors and 64 rolls are 4 floors. The 20-foot container holds about 22 tons.