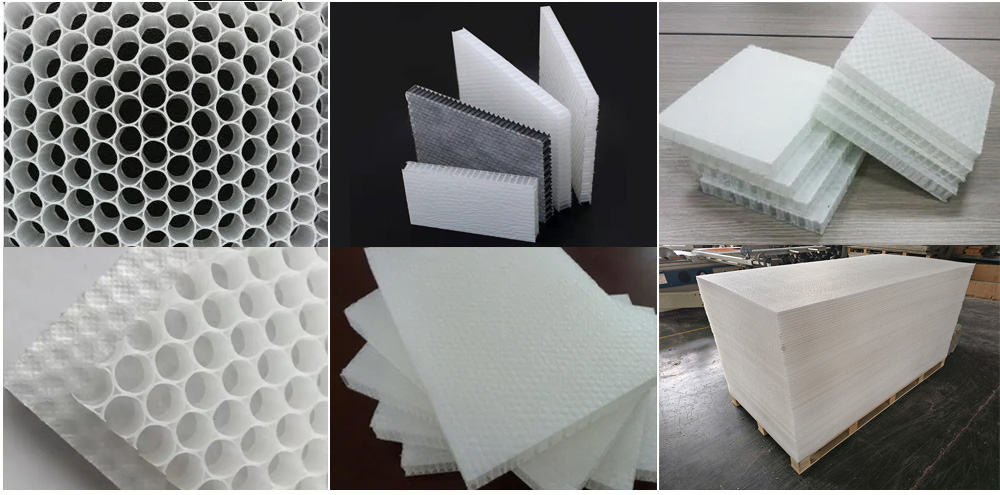

When it comes to lightweight yet durable materials, PP honeycomb core stands out as a versatile and efficient option suitable for a variety of applications. This innovative material is made from polypropylene, a thermoplastic polymer known for its strength and elasticity. The material’s unique honeycomb structure provides an excellent strength-to-weight ratio, making it ideal for industries such as aerospace, automotive, marine and construction.

One of the main advantages of PP honeycomb core is its lightweight nature. The honeycomb structure consists of interconnected hexagonal cells forming a strong and rigid core while keeping overall weight to a minimum. This makes it an excellent choice for applications where weight reduction is critical, such as aircraft components, automotive body panels and shipbuilding. The lightweight nature of PP honeycomb core also helps improve fuel efficiency and overall performance in various industries.

In addition to its lightweight properties, PP honeycomb core offers excellent strength and impact resistance. The honeycomb structure distributes the load evenly across the material, providing high strength and stiffness. This makes it ideal for structural components in the aerospace and automotive industries, where durability and reliability are critical. The impact resistance of PP honeycomb core also makes it suitable for applications that need to withstand external forces, such as protective packaging and construction materials.

In addition, PP honeycomb core material is known for its excellent thermal and sound insulation properties. The air-filled cells within the honeycomb structure act as a thermal barrier, providing insulation to regulate temperature and reduce energy consumption. This makes it ideal for applications where thermal management is critical, such as buildings and HVAC systems. Additionally, the sound-insulating properties of PP honeycomb core make it suitable for acoustic panels and noise control applications.

In addition, PP honeycomb core materials are highly customizable and can be tailored to meet specific design requirements. It can be easily formed, cut and shaped to suit a variety of applications, allowing for design and manufacturing flexibility. This versatility makes it a popular choice for industries that require complex and custom components, such as furniture manufacturing, signage, and interior design. The ability to customize PP honeycomb core also extends to its surface treatment, allowing for a variety of aesthetic options to suit different design preferences.

In summary, PP honeycomb core offers a winning combination of lightweight, strength, insulation and customization, making it the first choice for a variety of industries. Its unique performance and versatility make it an attractive choice for applications where performance, efficiency and design flexibility are critical. As technology and innovation continue to drive advancements in materials science, PP honeycomb cores will play a key role in shaping the future of lightweight, durable solutions across industries.

Post time: Mar-28-2024