Over the past two years, driven by the technological evolution of thermal runaway protection materials for new energy batteries, customers increasingly demand enhanced thermal insulation performance alongside ceramic-like ablation resistance—a key property for withstanding flame impact.

For instance, some applications require front-side flame ablation temperatures of 1200°C while maintaining back-side temperatures below 300°C. In aerospace materials, front-side acetylene flame ablation at 3000°C demands back-side temperatures under 150°C. Particularly challenging is the heightened demand for compression performance in ceramicized silicone foam, which requires both low compression set and excellent thermal insulation retention at high temperatures. These materials collectively present new thermal insulation demands for ceramicization technology.

Specific performance requirements (for reference only):

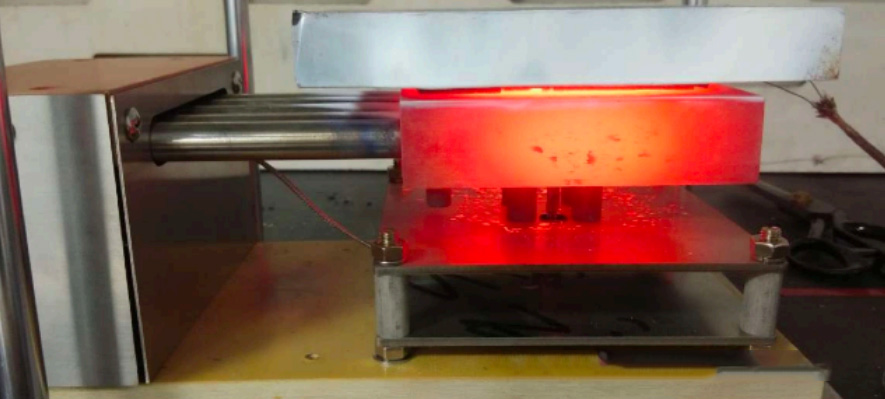

Heat the sample on a heating platform as shown below. Maintain the hot surface at 600 ± 25 °C for 10 minutes. Apply a stress of 0.8±0.05 MPa at the test temperature, ensuring the back surface temperature remains below 200°C.

Today, we summarize these points for your reference.

1. Synthetic Calcium Silicate – Thermal Insulation White Filler

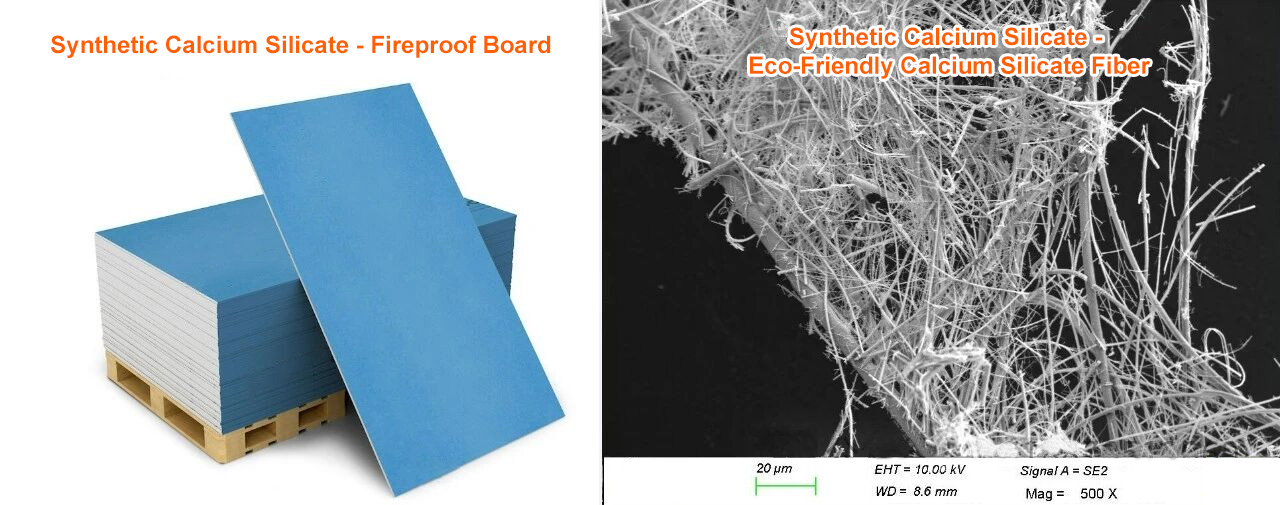

Synthetic calcium silicate exists in two forms: porous/spherical structures and ceramic-fiber-like fibrous structures. Despite compositional and morphological differences, both serve as excellent high-temperature resistant thermal insulation white fillers.

Synthetic calcium silicate fiber is an environmentally friendly and safe thermal insulation material with high-temperature resistance up to 1200-1260°C. Specially processed synthetic calcium silicate fiber powder can serve as a fiber-reinforced material for high-temperature insulation.

Synthetic porous or spherical calcium silicate, meanwhile, features high whiteness, ease of incorporation, a rich nanoporous structure, ultra-high oil absorption values (up to 400 or higher), and freedom from slag balls or large particles. It has proven applications in high-temperature resistant insulation and fireproof panels, demonstrating feasibility for incorporation into ceramicized ablation-resistant materials to provide high-temperature insulation.

Other applications include: powdered liquid additives, high-temperature insulating powder coatings, perfume adsorbent carriers, anti-drip agents, brake pad friction materials, low-pressure silicone rubber and self-decomposing silicone oil, paper fillers, etc.

2. Layered Porous Magnesium Aluminum Silicate – Thermal Insulation & High-Temperature Resistance

This silicate mineral requires high-temperature calcination with a refractoriness up to 1200°C. Primarily composed of magnesium aluminum silicate, it features a rich layered porous structure offering high bonding strength, excellent water resistance, prolonged refractory duration, and high cost-effectiveness.

Its primary functions include high-temperature insulation, density reduction, enhanced refractoriness, and improved ablation resistance and thermal insulation for carbon layers and casings. Applications include ceramicized insulation materials, premium fireproof coatings, refractory insulation materials, and ablation-resistant thermal insulation materials.

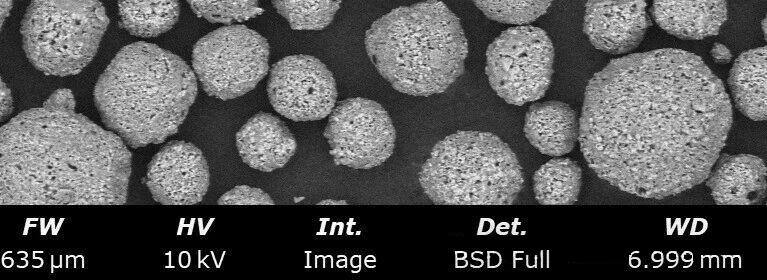

3. Ceramic Microspheres – High-Temperature Resistance, Thermal Insulation, Compressive Strength

Hollow glass microspheres are undoubtedly excellent thermal insulation materials, but their temperature resistance is insufficient. Their softening points generally range from 650-800°C, with melting temperatures at 1200-1300°C. This limits their application to low-temperature thermal insulation scenarios. Under higher-temperature conditions like ceramicization and ablation resistance, they become ineffective.

Our hollow ceramic microspheres resolve this issue. Primarily composed of aluminosilicate, they offer high-temperature resistance, outstanding thermal insulation, high refractoriness, and superior fracture resistance. Applications include silicone ceramic additives, refractory insulation materials, high-temperature additives for organic resins, and high-temperature resistant rubber additives. Key sectors encompass aerospace, deep-sea exploration, composite materials, coatings, refractory insulation, petroleum industry, and insulation materials.

This is a more heat-resistant hollow spherical micropowder that is extremely easy to incorporate (unlike hollow glass microspheres, which require pre-dispersion or modification for proper addition) and exhibits excellent crack resistance. Its distinguishing feature is that it is a surface-open material that does not float on water, making it relatively easy to thicken and settle.

Additionally, a brief mention of aerogel powder—a synthetic porous silica insulation material. Aerogel is widely recognized as an excellent thermal insulator, available in hydrophobic/hydrophilic variants. This allows selection of appropriate treatment methods based on resin substrates, addressing aerogel powder’s challenges of ultra-lightweight dispersion and improving its dispersibility. Water-based aerogel pastes are also available for convenient incorporation into aqueous systems.

The unique porous thermal insulation properties of aerogel powder enable its application in: – Rubber and plastic additive carriers – Thermal insulation materials for new energy batteries – Building insulation coatings – Thermal insulation textile fibers – Building insulation panels – Fireproof thermal insulation coatings – Thermal insulation adhesives.

Post time: Sep-22-2025