Pultruded FRP Grating

Introduction to FRP Grating Products

Pultruded fiberglass grating is manufactured using the pultrusion process. This technique involves continuously pulling a mixture of glass fibers and resin through a heated mold, forming profiles with high structural consistency and durability. This continuous production method ensures product uniformity and high quality. Compared to traditional manufacturing techniques, it allows for more precise control over fiber content and resin ratio, thereby optimizing the mechanical properties of the final product.

The load-bearing components feature I-shaped or T-shaped profiles connected by specialized round rods as crossbars. This design achieves an optimal balance between strength and weight. In structural engineering, I-beams are widely recognized as highly efficient structural members. Their geometry concentrates most material in the flanges, delivering exceptional resistance to bending stresses while maintaining low self-weight.

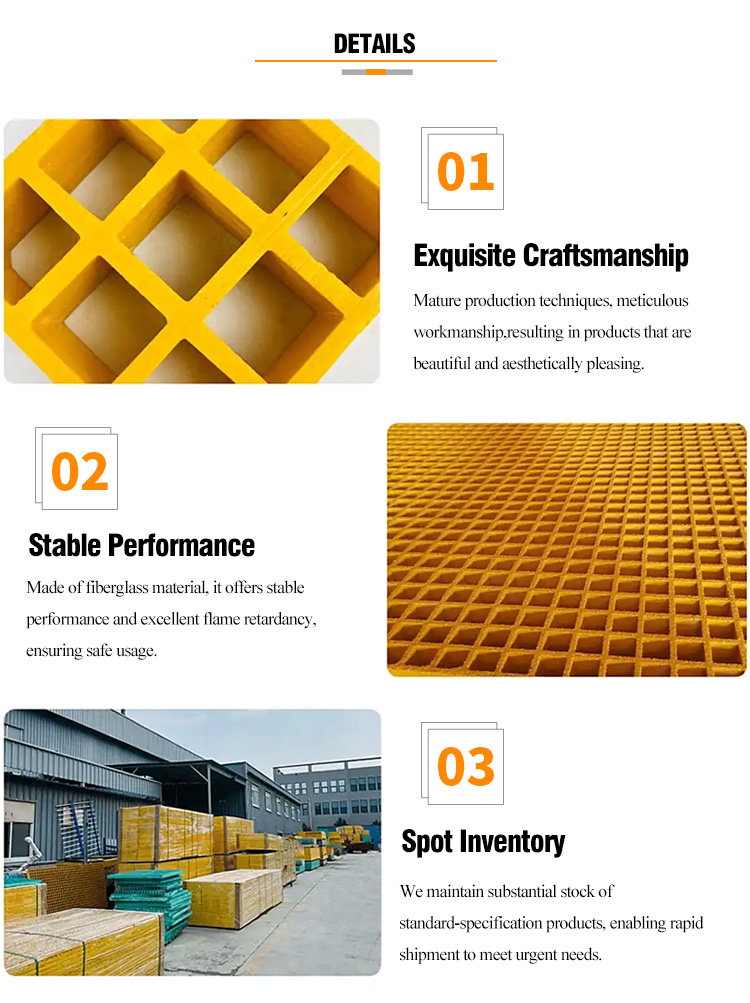

Core Advantages and Performance Characteristics

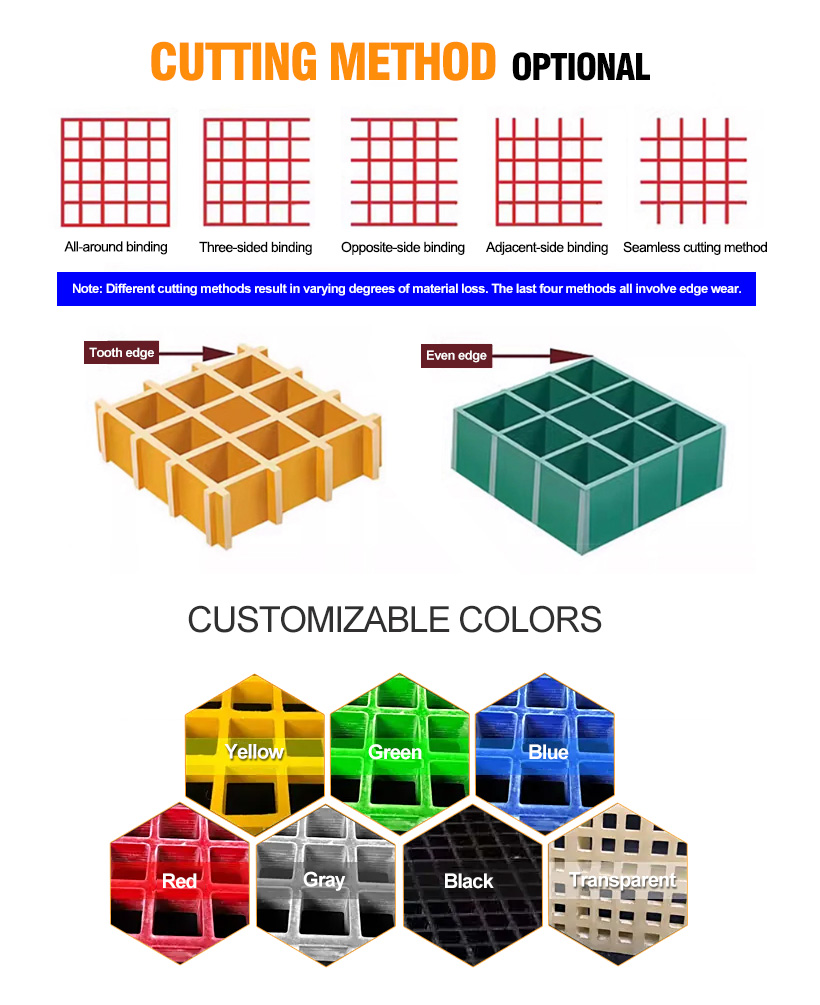

As a high-performance composite material, fiberglass (FRP) grating plays an increasingly vital role in modern industrial and infrastructure applications. Compared to traditional metal or concrete materials, FRP grating offers distinct advantages such as exceptional corrosion resistance, high strength-to-weight ratio, electrical insulation properties, and low maintenance requirements. Furthermore, FRP grating is manufactured using the pultrusion process to form “I” or “T” profiles as load-bearing members. Special rod seats connect the crossbars, and through specific assembly techniques, a perforated panel is created. The surface of pultruded grating features grooves for slip resistance or is coated with an anti-slip matte finish. Depending on practical application requirements, diamond-patterned plates or sand-coated plates can be bonded to the grating to create a closed-cell design. These characteristics and designs make it an ideal alternative for chemical plants, wastewater treatment facilities, power plants, offshore platforms, and other locations requiring resistance to corrosive environments or strict conductivity requirements.

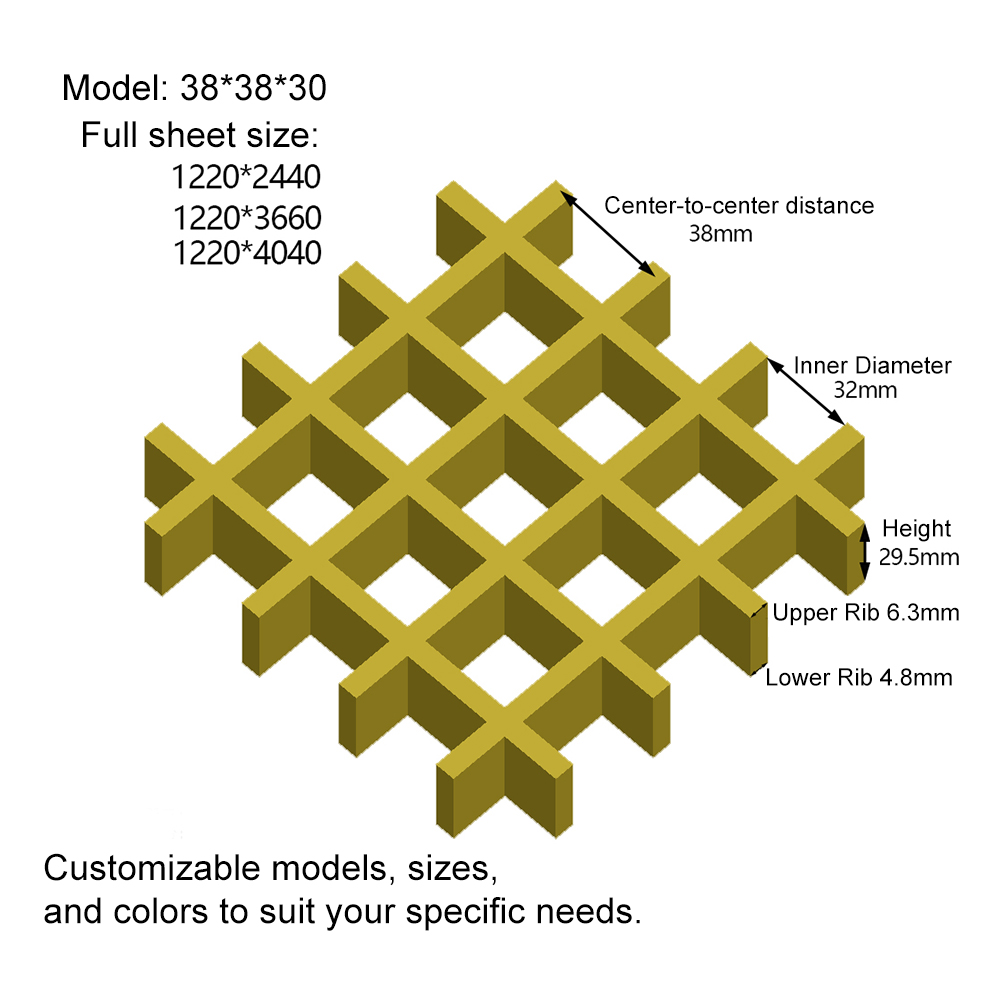

Grating Cell Shape and Technical Specifications

1. Pultruded Fiberglass Grating – T Series Model Specifications

2. Pultruded FRP Grating – I Series Model Specifications

|

Model |

Height A (mm) |

Top Edge Width B (mm) |

Opening Width C (mm) |

Open Area % |

Theoretical Weight (kg/m²) |

|

T1810 |

25 |

41 |

10 |

18 |

13.2 |

|

T3510 |

25 |

41 |

22 |

35 |

11.2 |

|

T3320 |

50 |

25 |

13 |

33 |

18.5 |

|

T5020 |

50 |

25 |

25 |

50 |

15.5 |

|

I4010 |

25 |

15 |

10 |

40 |

17.7 |

|

I4015 |

38 |

15 |

10 |

40 |

22 |

|

I5010 |

25 |

15 |

15 |

50 |

14.2 |

|

I5015 |

38 |

15 |

15 |

50 |

19 |

|

I6010 |

25 |

15 |

23 |

60 |

11.3 |

|

I6015 |

38 |

15 |

23 |

60 |

16 |

|

Span |

Model |

250 |

500 |

1000 |

2000 |

3000 |

4000 |

5000 |

10000 |

15000 |

|

610 |

T1810 |

0.14 |

0.79 |

1.57 |

3.15 |

4.72 |

6.28 |

7.85 |

- |

- |

|

I4010 |

0.20 |

0.43 |

0.84 |

1.68 |

2.50 |

3.40 |

4.22 |

7.90 |

12.60 |

|

|

I5015 |

0.08 |

0.18 |

0.40 |

0.75 |

1.20 |

1.50 |

1.85 |

3.71 |

5.56 |

|

|

I6015 |

0.13 |

0.23 |

0.48 |

0.71 |

1.40 |

1.90 |

2.31 |

4.65 |

6.96 |

|

|

T3320 |

0.05 |

0.10 |

0.20 |

0.41 |

0.61 |

0.81 |

1.05 |

2.03 |

3.05 |

|

|

T5020 |

0.08 |

0.15 |

0.28 |

0.53 |

0.82 |

1.10 |

1.38 |

2.72 |

4.10 |

|

|

910 |

T1810 |

1.83 |

3.68 |

7.32 |

14.63 |

- |

- |

- |

- |

- |

|

I4010 |

0.96 |

1.93 |

3.90 |

7.78 |

11.70 |

- |

- |

- |

- |

|

|

I5015 |

0.43 |

0.90 |

1.78 |

3.56 |

5.30 |

7.10 |

8.86 |

- |

- |

|

|

I6015 |

0.56 |

1.12 |

2.25 |

4.42 |

6.60 |

8.89 |

11.20 |

- |

- |

|

|

T3320 |

0.25 |

0.51 |

1.02 |

2.03 |

3.05 |

4.10 |

4.95 |

9.92 |

- |

|

|

T5020 |

0.33 |

0.66 |

1.32 |

2.65 |

3.96 |

5.28 |

6.60 |

- |

- |

|

|

1220 |

T1810 |

5.46 |

10.92 |

- |

- |

- |

- |

- |

- |

- |

|

I4010 |

2.97 |

5.97 |

11.94 |

- |

- |

- |

- |

- |

- |

|

|

I5015 |

1.35 |

2.72 |

5.41 |

11.10 |

- |

- |

- |

- |

- |

|

|

I6015 |

1.68 |

3.50 |

6.76 |

13.52 |

- |

- |

- |

- |

- |

|

|

T3320 |

0.76 |

1.52 |

3.05 |

6.10 |

9.05 |

- |

- |

- |

- |

|

|

T5020 |

1.02 |

2.01 |

4.03 |

8.06 |

- |

- |

- |

- |

- |

|

|

1520 |

T3320 |

1.78 |

3.56 |

7.12 |

- |

- |

- |

- |

- |

- |

|

T5020 |

2.40 |

4.78 |

9.55 |

- |

- |

- |

- |

- |

- |

Application Fields

Petrochemical Industry: In this sector, gratings must withstand corrosion from various chemicals (acids, alkalis, solvents) while meeting stringent fire safety standards. Vinyl Chloride Fiber (VCF) and Phenolic (PIN) gratings are ideal choices due to their exceptional corrosion resistance and high flame retardancy.

Offshore Wind Power: The salt spray and high humidity of marine environments are highly corrosive. Vinyl-chloride-based (VCF) grating’s exceptional corrosion resistance enables it to withstand seawater erosion, ensuring the structural safety and service life of offshore platforms.

Rail Transit: Rail transit facilities demand materials with durability, load-bearing capacity, and fire resistance. Grating is suitable for maintenance platforms and drainage channel covers, where its high strength and corrosion resistance withstand frequent use and complex environments.