In the process of human industrial civilization, thermal protection and fire suppression have always been core issues in ensuring the safety of life and property. With the evolution of materials science, the base materials of fire-resistant fabrics have gradually shifted from early natural minerals such as asbestos to high-performance synthetic fibers. Among the many material choices, fiberglass, with its excellent thermal stability, mechanical strength, electrical insulation, and extremely high cost-effectiveness, has established its dominant position as the mainstream base material in the global fire-resistant fabric field.

Physical and Chemical Properties and Thermal Protection Mechanism of Fiberglass

Silica Network and Atomic-Level Thermal Stability

The excellent fire-resistant performance of fiberglass stems from its unique microscopic atomic structure. Fiberglass is mainly composed of a disordered continuous network of silicon-oxygen tetrahedra (SiO2). The covalent bonds in this inorganic network structure have extremely high bond energy, allowing the material to exhibit excellent thermal stability in high-temperature environments. Unlike organic fibers such as cotton and polyester, fiberglass does not contain flammable long-chain hydrocarbons, so it does not undergo oxidative combustion when exposed to flames, nor does it release combustion-supporting gases.

According to thermodynamic analysis, the softening point of standard E-glass fiber is between 550°C and 580°C, while its mechanical properties remain extremely stable in the temperature range of 200°C to 250°C, with almost no reduction in tensile strength. This characteristic ensures the extremely high structural integrity of fiberglass fire-resistant fabrics in the early stages of a fire, effectively acting as a physical barrier to prevent the spread of fire.

Heat Conduction Inhibition and Air Trapping Effect

The core function of fire-resistant materials, in addition to non-flammability, lies in their control of heat transfer. Fiberglass fire-resistant fabrics exhibit a very low effective thermal conductivity, a phenomenon that can be explained from both macroscopic materials science and microscopic geometry perspectives.

1. Thermal Resistance of Static Air Layer: The thermal conductivity of glass blocks is usually between 0.7 and 1.3 W/(m*K), however, when made into fiberglass fabric, its thermal conductivity can be significantly reduced to about 0.034 W/(m*K). This significant reduction is mainly due to the large number of micron-sized voids between the fibers. In the interwoven structure of fire-resistant fabric, air is “trapped” within the fiber gaps. Due to the extremely low thermal conductivity of air molecules and the inability to form effective convective heat transfer in these tiny spaces, these air layers constitute an excellent thermal insulation barrier.

2. Multi-level thermal barrier construction: Through layered structure design, heat transfer from the high-temperature side to the low-temperature side requires crossing tens of thousands of fiber interfaces. Each interface contact generates significant thermal resistance and triggers phonon scattering effects, thus greatly dissipating the conducted thermal energy. For aerospace-grade ultra-fine glass fiber felt, this layered structure can also effectively reduce the “thermal bridge” effect in the thickness direction, further improving thermal insulation performance.

Manufacturing Process and Structural Stability Analysis

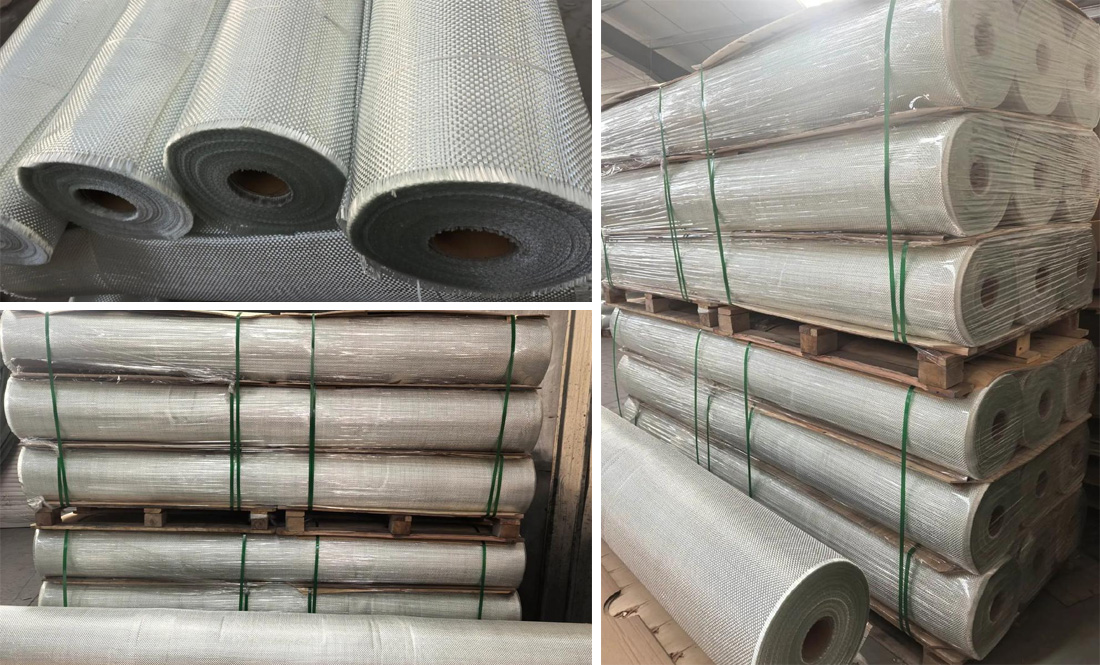

The performance of glass fiber fire-resistant fabric depends not only on its chemical composition but also on its weaving structure (Weave Style). Different weaving methods determine the fabric’s stability, flexibility, breathability, and bonding strength with coatings.

1.Stability Advantages of Plain Weave

Plain weave is the most basic and widely used weaving form, where warp and weft yarns interlace in an over-and-under pattern. This structure has the densest interlacing points, giving the fire-resistant fabric excellent dimensional stability and low yarn slippage. In building fire-resistant mesh fabrics and simple fire blankets, the plain weave structure ensures that the material maintains a tight physical barrier when deformed by heat, preventing flame penetration.

2.Flexibility Compensation of Twill and Satin Weaves

For fire protection applications requiring covering complex geometric shapes (such as pipe elbows, valves, and turbines), the rigidity of the plain weave structure becomes a limitation. In this case, twill or satin weaves exhibit superior conformability.

Twill weave: By forming diagonal lines, the frequency of warp and weft interlacing is reduced, making the fabric surface tighter and providing better drape.

Satin Weave: Such as four-harness (4-H) or eight-harness (8-H) satin weave, which features longer “floats.” This structure allows for greater freedom of movement of the fibers when subjected to stretching or bending, making satin weave fiberglass fabric an ideal choice for manufacturing high-temperature removable insulation covers, where its tight fit minimizes energy loss.

Surface Engineering: Extending the performance of fire-resistant fabrics through coating technology

Due to the inherent drawbacks of raw fiberglass, such as brittleness, poor abrasion resistance, and the tendency to produce irritating dust, modern high-performance fire-resistant fabrics typically apply various coatings to the surface of the base fabric to achieve comprehensive performance improvements.

Economical Protection with Polyurethane (PU) Coating

Polyurethane coatings are commonly used in smoke curtains and lightweight fire barriers. Their core value lies in stabilizing the fiber structure, improving the fabric’s puncture resistance and ease of processing. Although PU resin undergoes thermal degradation at around 180°C, by introducing micronized aluminum into the formulation, even if the organic components decompose, the remaining metal particles can still provide significant radiant heat reflection, thus maintaining the fabric’s structural protection at high temperatures of 550°C to 600°C. In addition, PU-coated fire-resistant fabrics have good sound insulation properties and are often used as thermal protection and sound-absorbing linings for ventilation ducts.

The Evolution of Weather Resistance with Silicone Coating

Silicone-coated fiberglass fabric represents a high-end application direction in the field of thermal protection. Silicone resin possesses excellent flexibility, hydrophobicity, and chemical stability.

Extreme Temperature Range Adaptability: Its operating temperature covers -70°C to 250°C, and it produces extremely low concentrations of smoke when heated, complying with strict fire safety regulations.

Chemical Corrosion Resistance: In the petrochemical and marine industries, fire-resistant fabrics are often exposed to lubricating oils, hydraulic fluids, and seawater salt spray. Silicone coatings can effectively prevent these chemical media from penetrating into the fibers, avoiding sudden strength loss due to stress corrosion.

Electrical Insulation: Combined with a fiberglass substrate, silicone-coated fabric is the preferred material for fire-resistant cladding of power cables.

Vermiculite Coating: Ultra-High Temperature Breakthrough

When the application environment involves molten metal splashes or direct welding sparks, mineral coatings demonstrate overwhelming advantages. Vermiculite coating significantly enhances the material’s instantaneous thermal shock resistance by forming a protective film composed of natural silicate minerals on the fiber surface. This composite fabric can operate continuously for extended periods at 1100°C, withstand temperatures up to 1400°C for short periods, and even resist instantaneous high temperatures of 1650°C. Vermiculite coating not only improves wear resistance but also has good dust suppression effects, providing a safer working environment for high-temperature operations.

Aluminum Foil Lamination and Radiant Heat Management

By laminating aluminum foil onto the surface of fiberglass fabric using adhesive or extrusion processes, an excellent radiant heat barrier can be created. The high reflectivity of aluminum foil (typically > 95%) effectively reflects infrared radiation emitted by industrial furnaces or high-temperature pipes. This type of material is widely used in fire blankets, fire curtains, and building wall coverings, not only providing fire protection but also achieving significant energy savings through heat reflection.

Global Market Dynamics and Cost Efficiency

The cost-effectiveness of fiberglass fire-resistant fabric is the ultimate embodiment of its core competitiveness. Economic forecasts for 2025 indicate that due to the high degree of automation in pultrusion and weaving processes, the unit price of fiberglass will remain stable at a low level in the long term. This low cost makes fire safety no longer the exclusive domain of high-end equipment, but accessible to ordinary homes and small workshops.

Sustainability and Circular Economy

With the popularization of ESG (Environmental, Social, and Governance) principles, the recycling of fiberglass is making breakthroughs.

Material Recycling: Old fiberglass fire-resistant fabric can be crushed and reused as a reinforcing material for concrete or as a raw material for manufacturing refractory bricks. Energy-saving effect: Fiberglass insulation sleeves directly reduce carbon emissions by minimizing industrial heat loss, giving them profound strategic value in the industrial context of pursuing “dual carbon” goals.

The reason fiberglass has become the preferred material for fire-resistant fabrics is a natural consequence of its chemical nature and engineering innovation. At the atomic level, it achieves thermal stability through the bond energy of the silicon-oxygen network; at the structural level, it creates an efficient thermal barrier by trapping static air within the fibers; at the process level, it compensates for physical defects through multi-layer coating technology; and at the economic level, it establishes unparalleled competitive advantages through economies of scale.

Post time: Jan-19-2026