Some kinds of 3D printed objects can now be “feeled”, using a new technology to build sensors directly into their materials. A new study found that this research may lead to new interactive devices, such as smart furniture.

This new technology uses metamaterials-substances made up of a grid of repeating units-to 3D print objects. When force is applied to a flexible metamaterial, some of their cells may stretch or compress. The electrodes incorporated into these structures can detect the magnitude and direction of these shape changes, as well as rotation and acceleration.

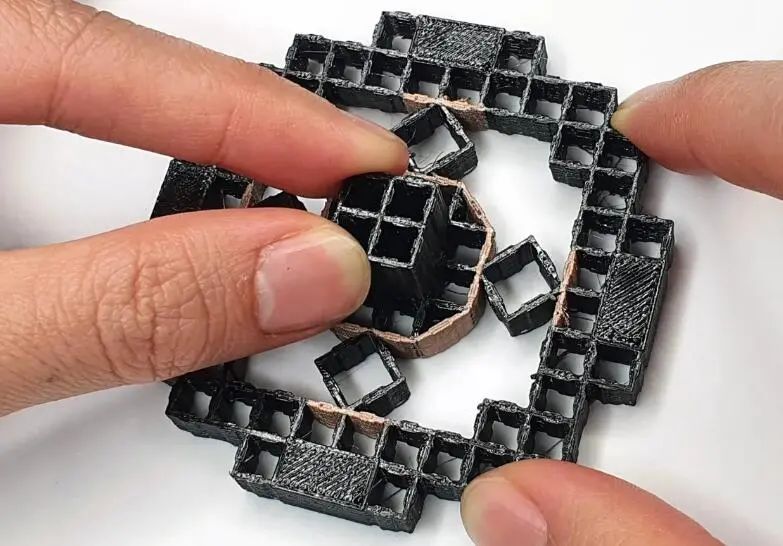

In this new study, the researchers fabricated objects made of flexible plastic and conductive filaments. These have cells as small as 5 mm wide.

Each cell has two opposing walls made of conductive filaments and non-conductive plastic, and the conductive walls serve as electrodes. The force applied to the object changes the distance and overlap area between the opposing electrodes, producing an electrical signal that shows details about the force applied. The co-author of the research report said that in this way, this new technology can “seamlessly and unobtrusively integrate sensing technology into printed objects.”

Researchers say that these metamaterials can help designers quickly create and adjust flexible computer input devices. For example, they used these metamaterials to create a music controller designed to fit the shape of a human hand. When the user squeezes one of the flexible buttons, the electrical signal generated helps to control a digital synthesizer.

The scientists also made a metamaterial joystick to play Pac-Man. By understanding how people apply force on this joystick, designers can design unique handle shapes and sizes for people with limited grip in certain directions.

The co-author of the research report said: “We can perceive motion in any 3D printed object. From music to game interfaces, the potential is really exciting.”

Researchers have also created 3D editing software, called MetaSense, to help users build interactive devices using these metamaterials. It simulates how a 3D printed object deforms when different forces are applied, and calculates which cells change the most and are most suitable for use as electrodes.

MetaSense enables designers to 3D print structures with built-in sensing capabilities in one go. This makes the prototyping of devices super fast, such as joysticks, which can be customized for individuals with different accessibility needs.

Embedding hundreds or thousands of sensor units in an object can help achieve high-resolution, real-time analysis of how users interact with it. For example, a smart chair made of this metamaterial can detect the user’s body, and then turn on a light or TV, or collect data for later analysis, such as detecting and correcting body posture. These metamaterials may also find use in wearable applications.

Post time: Sep-27-2021