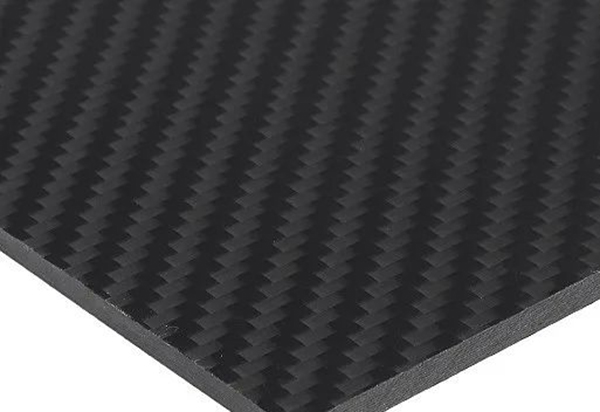

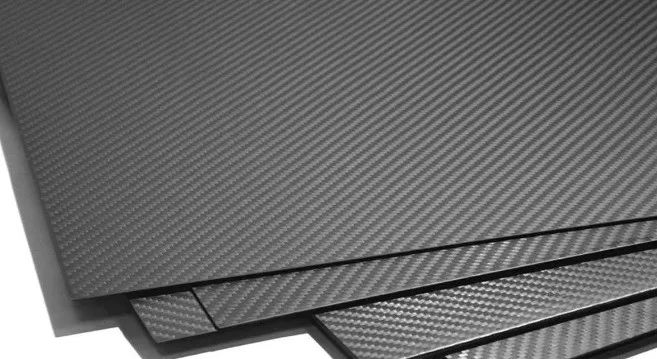

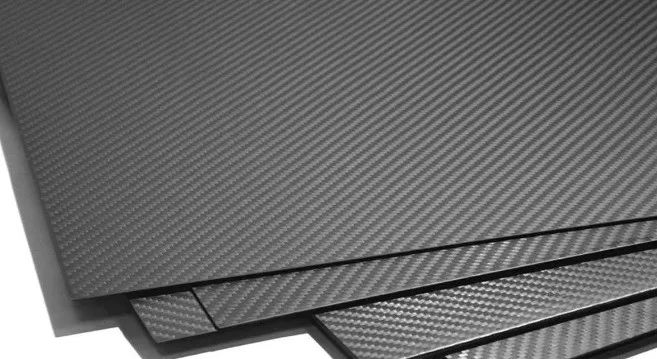

Carbon fiber board is a structural material prepared from a composite material composed of carbon fiber and resin. Due to the unique properties of the composite material, the resulting product is lightweight yet strong and durable.

In order to adapt to applications in different fields and industries including aerospace, automotive industry, etc., carbon fiber sheets will also have many different types. In this article, we’ll take a closer look at where carbon fiber sheets are applied and how strong they are compared to other materials.

In which areas will carbon fiber panels be used?

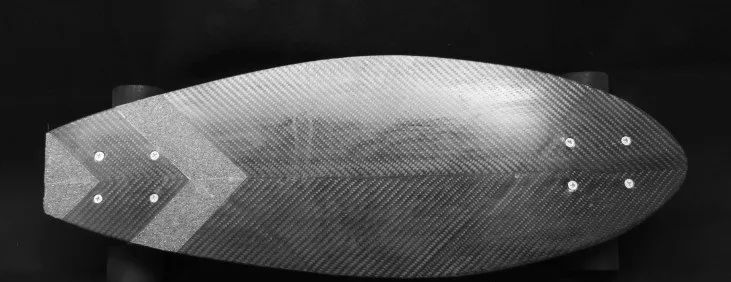

Carbon fiber sheets and sheets can be used in a wide variety of industries, including automotive, aerospace, musical instruments, sporting goods, and medical devices.

In the automotive industry, carbon fiber sheets are used to strengthen automotive components such as doors, hoods, bumpers, fenders and roof rails. Automakers often use steel to make these parts. Steel, while cheaper, is much heavier than carbon fiber. To make vehicles such as race cars lighter, carbon fiber sheets are often used to replace many steel parts.

In the aerospace industry, carbon fiber sheets are used to make aircraft components such as fuselage panels, control surfaces and wingtips. The resulting components are lightweight, yet robust. Carbon fiber is widely adopted by the aerospace industry due to its superior strength-to-weight ratio. Because carbon fiber has such a beautiful appearance, it is also ideal for aircraft interiors.

Similar to automotive structural materials, materials such as aluminum and steel are commonly used to make aircraft. However, commercial airlines are increasingly using carbon fiber composites to create lighter and stronger airframes. This is because carbon fiber is much lighter than steel, much lighter than aluminum, and much stronger, and can be formed into any shape.

How strong are carbon fiber panels?

When comparing carbon fiber to other materials such as steel and aluminum, a number of properties are taken into account. Here are some performance metrics commonly used for comparison:

- Modulus of elasticity = stiffness of the material. The ratio of stress to strain in a material. The slope of the stress-strain curve of the material in the elastic region.

- Ultimate Tensile Strength = The maximum stress a material can withstand before breaking.

- Density = mass of material per unit volume.

- Specific stiffness = elastic modulus divided by material density, used to compare materials with different densities.

- Specific tensile strength = tensile strength divided by material density.

Carbon fiber sheets have a very high strength-to-weight ratio, which means they are much stronger than other materials of the same weight, for example, carbon fiber has a specific strength that is almost 4 times that of aluminum, which makes carbon fiber sheets an ideal material for a variety of applications, especially is when weight is an important factor.

While both carbon fiber and steel are very resistant to deformation, steel is 5 times denser than carbon fiber. The weight-to-weight ratio of carbon fiber is almost twice that of steel.

To sum up, carbon fiber board is a kind of composite material with high strength, light weight and versatility. In many industries, the strength-to-weight ratio of carbon fiber provides significant performance advantages.

Post time:

May-13-2022