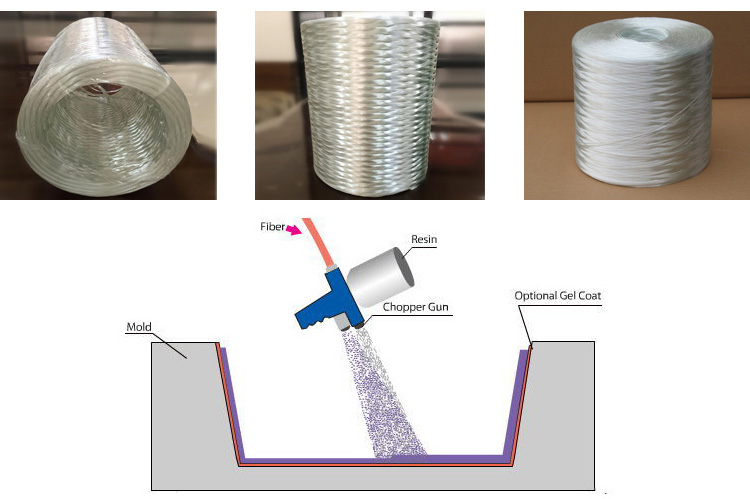

Method Description:

Spray molding composite material is a molding process in which short-cut fiber reinforcement and resin system are simultaneously sprayed inside a mold and then cured under atmospheric pressure to form a thermoset composite product.

Material Selection:

- Resin: mainly polyester

- Fiber: E-Glass Assembled Roving For Spray Up

- Core material: none, need to be combined with laminate alone

Main Advantages:

- Long history of craftsmanship

- Low cost, fast lay-up of fibers and resins

- Low mold cost

Epoxy curing agent R-3702-2

- R-3702-2 is an alicyclic amine modified curing agent, which has the advantages of low viscosity, low odor, and long operating time. Good toughness and high mechanical strength of the cured product, but also has good temperature and chemical resistance, Tg value up to 100 ℃.

- Application: glass fiber reinforced plastic products, epoxy pipe winding, various pultrusion molding products

Epoxy curing agent R-2283

- R-2283 is an alicyclic amine modified curing agent. It has the advantages of light color, fast curing, low viscosity, etc.. The hardness of the cured product is high, and the weather resistance and mechanical properties are excellent.

- Use: sanding adhesive, electronic potting adhesive, hand paste molding process products

Epoxy curing agent R-0221A/B

- R-0221A/B is a laminated resin with low odor, high temperature resistance, high mechanical strength, and excellent chemical resistance.

- Uses: structural parts production, resin infiltration process, hand paste FRP lamination, compound molding mold production (such as RTM and RIM)

Post time: Jun-27-2023