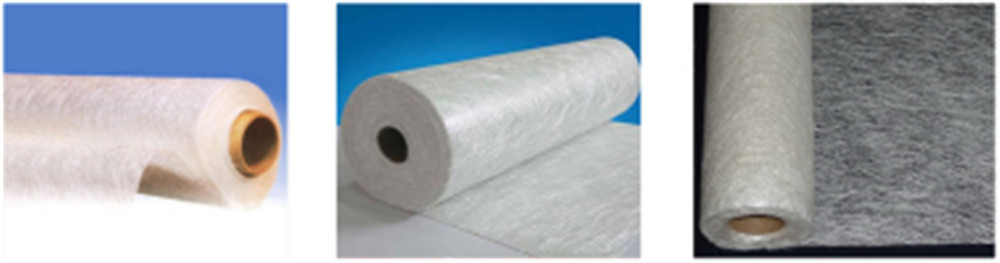

CSM

E-Glass Chopped Strand Mat are unwoven fabrics consisting of randomly distributed chopped stands held together with a powder/emulsion binder.

It is compatible with UP, VE, EP, PF resins. The roll width ranges from 50mm to 3300mm, areal weight ranges from 100gsm to 900gsm. Standard width1040/1250mm, roll weight 30kg. It is designed for use in hand lay-up, filament winding, compression molding and continuous laminating processes.

Product Features:

1) Fast breakdown in styrene

2) High tensile strength, allowing for use in hand lay-up process to produce large-area parts

3) Good wet-through and fast wet-out in resins, rapid air lease

4) Superior acid corrosion resistance

The end-use include boats, bath equipment, automotive parts, chemical corrosion resistant pipes, tanks, cooling towers and building components.

There is a difference in the hardness and softness of glass fiber chopped strand mat, which is due to the different surface treatment agents of glass fiber. As for the old FRP, they generally like the softer chopped felt, which makes it easier to stick the mold and corner position. This is a contradictory point. If it is softer, it means that the chopped strand mat is slightly fluffy or has no fiber residue, and has no texture. The representative product is powder chopped strand mat.

The emulsion felt is relatively hard, but it is quite flat. Most fiberglass workers like emulsion felt because it is easier to cut and the fiberglass will not fly everywhere.

Especially in the case of low temperature, the glass fiber will be harder than usual. It is generally recommended that you choose this way: in the case of complex mold and product structure, you choose powder felt to soak better, and it is also convenient for thick laying. Some large, smooth structure of the product manufacturing, you use emulsion felt will be faster and more comfortable.

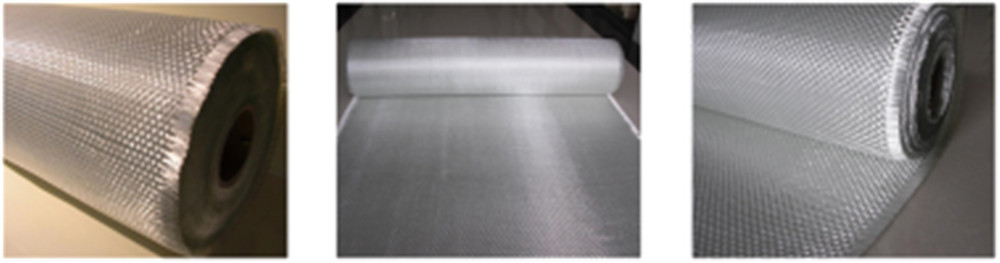

WRE

E-Glass Woven Rovings are bidirectional fabric made by interweaving direct rovings. WRE is compatible with unsaturated polyester, vinyl ester, epoxy and phenolic resins.

Product Features:

1) Warp and weft rovings aligned in a parallel and flat manner, resulting in uniform tension

2) Densely aligned fibers, resulting in high dimensional stability and making handling easy

3) Good moldability, fast and complete wet out in resins, resulting in high productivity

4) Good mechanical properties and high strength of parts

WRE are a high-performance reinforcement widely used in hand lay up and robot processes to manufacture boats, vessels, plane and automotive parts, furniture and sports facilities.

Free sample is available for CSM and WRE. The width and areal weight can be customized. For more information, please feel free to contact us.

Post time: Dec-22-2020