According to experts, steel has been a staple material in construction projects for decades, providing essential strength and durability. However, as steel costs continue to rise and concerns about carbon emissions increase, there is a growing need for alternative solutions.

Basalt rebar is a promising alternative that can solve both problems. Thanks to its excellent characteristics and environmental friendliness, it can truly be called a worthy alternative to conventional steel. Derived from volcanic rock, basalt steel bars have impressive tensile strength, making them suitable for use in a variety of construction applications.

Basalt rebar is a proven alternative to traditional steel or fiberglass reinforcement for concrete and is gaining momentum as an emerging technology in the UK. The use of this innovative solution on high-profile projects such as High Speed 2 (HS2) and the M42 motorway is becoming increasingly prominent in construction projects as decarbonisation efforts progress.

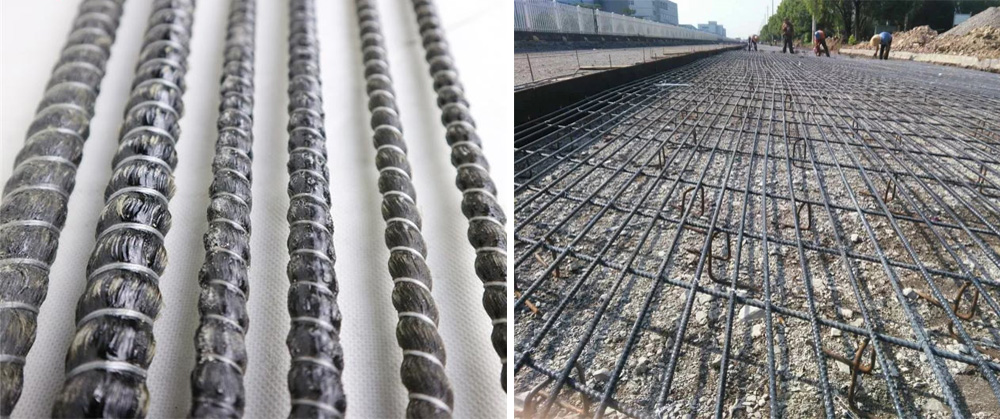

– The production process involves collecting volcanic basalt, crushing it into small pieces and holding it at temperatures up to 1400°C. The silicates in basalt turn it into a liquid that can be stretched by gravity through special plates, creating long lines that can reach thousands of meters in length. These threads are then wound onto spools and prepared to form reinforcement.

Pultrusion is used to transform basalt wire into steel rods. The process involves drawing out threads and dipping them into liquid epoxy resin. The resin, which is a polymer, is heated to a liquid state and then the threads are immersed in it. The entire structure hardens quickly, turning into a finished rod in a matter of minutes.

Post time: Oct-20-2023