Experimental proof

For every 10% reduction in vehicle weight, fuel efficiency can be increased by 6% to 8%. For every 100 kilograms of vehicle weight reduction, fuel consumption per 100 kilometers can be reduced by 0.3-0.6 liters, and carbon dioxide emissions can be reduced by 1 kilogram. The use of lightweight materials makes vehicles lighter. One of the main ways

Basalt fiber is a green and environmentally friendly high-performance fiber material. The production process is often used in the industry to describe its production process, which means that natural basalt ore is crushed and melted in the temperature range of 1450~1500℃, and then drawn into basalt fiber .

Basalt fiber has a series of advantages such as good mechanical properties, good high temperature resistance, stable chemical properties, environmental protection in the production process, and excellent comprehensive performance. The fiber-reinforced composite material prepared by compounding it with resin is a lightweight material with excellent performance

Basalt fiber helps lightweight cars

In recent years, lightweight cars made of basalt fiber composite materials have frequently appeared in major international auto shows.

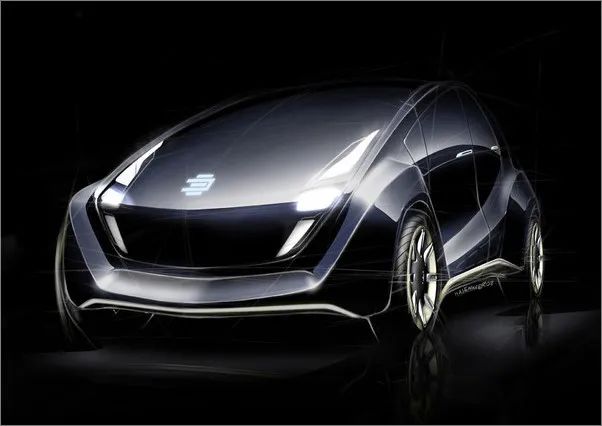

German Edag company Light Car concept car

Use basalt fiber composite materials to build the car body

It has the advantages of light weight and stability, 100% recyclable

Triaca230, an environmentally friendly concept car from Roller Team, Italy

The basalt fiber composite wallboard is adopted, which reduces the weight by 30% compared with traditional materials.

Urban electric vehicles launched by Russia’s Yo-motor company

Using basalt fiber composite material body, the total weight of the car is only 700kg.

Post time: Nov-12-2021