1. Glass Fiber Reinforced Plastic Doors and Windows

The lightweight and high tensile strength characteristics of Glass Fiber Reinforced Plastic (GFRP) materials largely compensate for the deformation drawbacks of traditional plastic steel doors and windows. Doors and windows made from GFRP can accommodate a wide range of door and window design requirements and offer good sound insulation. With a heat distortion temperature of up to 200 ℃, GFRP maintains excellent airtightness and good thermal insulation in buildings, even in northern regions with large temperature differences. According to building energy conservation standards, the thermal conductivity index is a key consideration for selecting doors and windows in the construction sector. Compared to existing aluminum alloy and plastic steel doors and windows on the market, high-quality GFRP doors and windows demonstrate superior energy-saving effects. In the design of these doors and windows, the interior of the frame often employs a hollow design, further enhancing the material’s thermal insulation performance and significantly absorbing sound waves, thereby improving the building’s sound insulation.

2. Glass Fiber Reinforced Plastic Formwork

Concrete is a widely used material in the construction industry, and formwork is a crucial tool for ensuring concrete is poured as intended. According to incomplete statistics, current construction projects require 4-5 m³ of formwork for every 1 m³ of concrete. Traditional concrete formwork is made from steel and wood. Steel formwork is hard and dense, making it difficult to cut during construction, which significantly increases the workload. While wooden formwork is easy to cut, its reusability is low, and the surface of the concrete produced using it is often uneven. GFRP material, on the other hand, has a smooth surface, is lightweight, and can be reused through splicing, offering a high turnover rate. Moreover, GFRP formwork boasts a simpler and more stable support system, eliminating the need for column clamps and support frames typically required by steel or wooden formwork. Bolts, angle iron, and guy ropes are sufficient to provide stable fixation for GFRP formwork, greatly improving construction efficiency. In addition, GFRP formwork is easy to clean; any dirt on its surface can be directly removed and cleaned, extending the formwork’s service life.

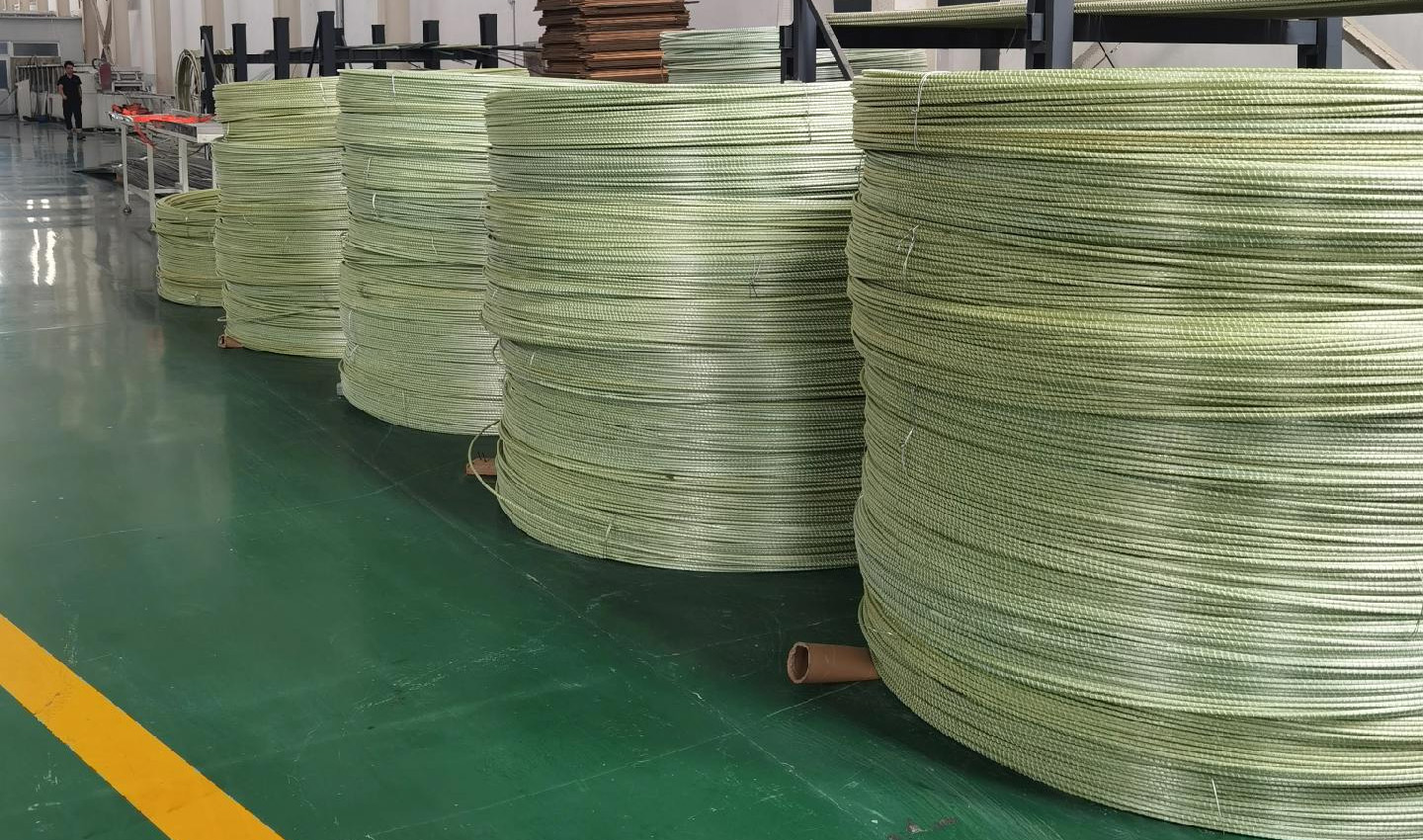

3. Glass Fiber Reinforced Plastic Rebar

Steel rebar is a commonly used material to enhance concrete strength. However, conventional steel rebar suffers from severe corrosion issues; when exposed to corrosive environments, corrosive gases, additives, and humidity, it can rust significantly, leading to concrete cracking over time and increasing building hazards. GFRP rebar, conversely, is a composite material with polyester resin as the base and glass fibers as the reinforcing material, formed through an extrusion process. In terms of performance, GFRP rebar exhibits excellent corrosion resistance, insulation, and tensile strength, greatly enhancing the flexural and impact resistance of the concrete matrix. It does not corrode in salt and alkali environments. Its application in special building designs holds broad prospects.

4. Water Supply, Drainage, and HVAC Pipes

The design of water supply, drainage, and ventilation pipes in building design contributes to the overall functionality of the building. Conventional steel pipes tend to rust easily over time and are difficult to maintain. As a rapidly developing pipe material, GFRP boasts high strength and a smooth surface. Choosing GFRP for ventilation ducts, exhaust pipes, and wastewater treatment equipment pipes in building water supply, drainage, and ventilation designs can significantly extend the pipes’ service life. Additionally, its excellent design flexibility allows designers to easily adjust the internal and external pressure of the pipes according to construction project requirements, enhancing the pipes’ bearing capacity.

Post time: Jul-23-2025