Low price for End To End Fiberglass Smc Roving - E-glass Assembled Roving For SMC – Beihai Fiberglass

Low price for End To End Fiberglass Smc Roving - E-glass Assembled Roving For SMC – Beihai Fiberglass Detail:

E-glass Assembled Roving For SMC

Assembled Roving for SMC is compatible with unsaturated polyester, vinyl ester resin, delivering good dispersion after chopping, low fuzz, fast wet out and low static.

Features

●Good dispersion after chopping

●Low fuzz

●Fast wet out

●Low static

Application

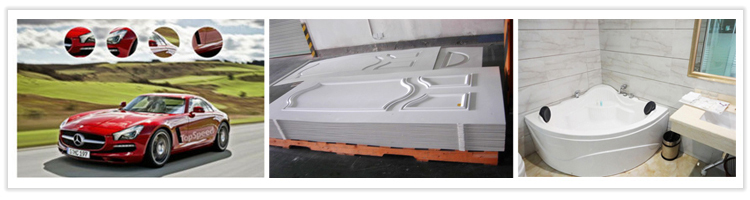

●Automotive parts: bumper, rear cover box, car door, headliner;

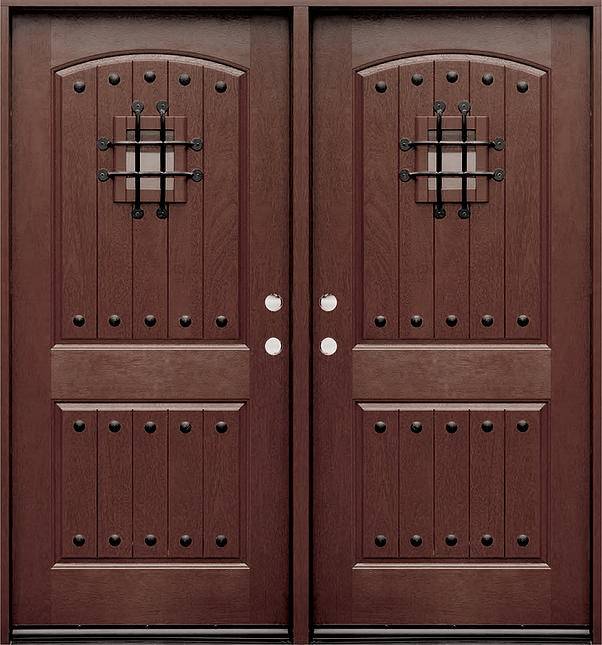

●Building & construction industry: SMC door, chair, sanitary ware, water tank, ceiling;

●Electronic & electrical industry: a variety of parts.

●In recreation industry: a variety of apparatus.

Product List

|

Item |

Linear Density |

Resin Compatibility |

Features |

End Use |

|

BHSMC-01A |

2400, 4392 |

UP, VE |

for general pigmentable SMC product |

truck parts, water tanks, door sheet and electrical parts |

|

BHSMC-02A |

2400, 4392 |

UP, VE |

high surface quality, low combustible content |

ceiling tiles, door sheet |

|

BHSMC-03A |

2400, 4392 |

UP, VE |

excellent hydrolysis resistance |

bathtub |

|

BHSMC-04A |

2400, 4392 |

UP, VE |

high surface quality, high combustible content |

bathroom equipment |

|

BHSMC-05A |

2400, 4392 |

UP, VE |

good choppability, excellent dispersion, low static |

automotive bumper and headliner |

| Identification | |

| Type of Glass |

E |

| Assembled Roving |

R |

| Filament Diameter, μm |

13, 14 |

| Linear Density, tex |

2400, 4392 |

| Technical Parameters | |||

|

Linear Density (%) |

Moisture Content (%) |

Size Content (%) |

Stiffness (mm) |

|

ISO 1889 |

ISO 3344 |

ISO 1887 |

ISO 3375 |

|

±5 |

≤0.10 |

1.25±0.15 |

160±20 |

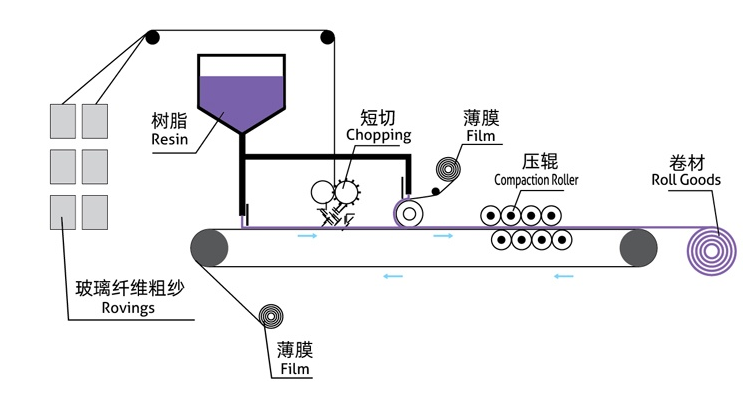

SMC Process

Mix the resins , fillers and other materials well to form a resin paste ,apply the paste on a first film , disperse chopped glass fibers evenly or the resin paste film and cover this paste film with another layer of resipaste film , and then compact the two paste films with pressure rollers of a SMC machine unit to form sheet molding compound products.

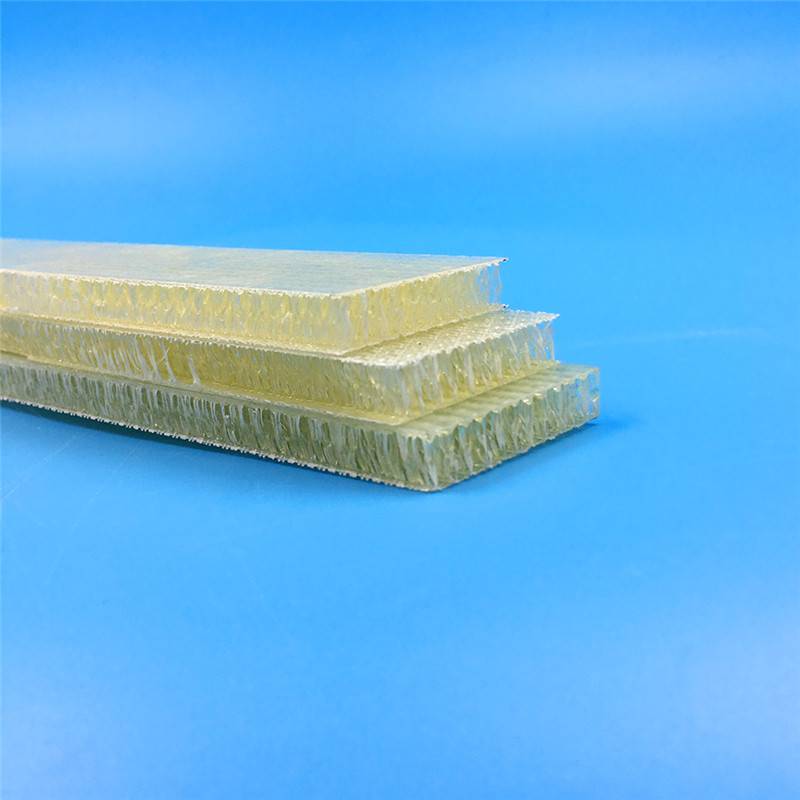

Product detail pictures:

Related Product Guide:

Our products are broadly regarded and reliable by end users and can meet up with constantly transforming financial and social requires of Low price for End To End Fiberglass Smc Roving - E-glass Assembled Roving For SMC – Beihai Fiberglass , The product will supply to all over the world, such as: Lahore, Macedonia, New Zealand, As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers,and establish a long term win-win business relationship. For more information,please contact us. And it's our great pleasure if you like to have a personally meeting in our office.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.