Good Quality Glass Fiber Roving Fibre Fiberglass For GRC In Building for SMC

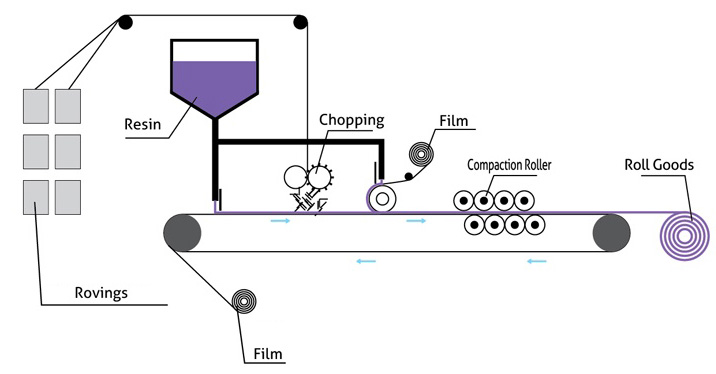

SMC Process

Mix the resins, fillers and other materials well to form a resin paste, apply the paste on a first film, disperse chopped glass fibers evenly or the resin paste film and cover this paste film with another layer of resil paste film, and then compact the two paste films with pressure rollers of a SMC machine unit to form sheet molding compound products.

Assembled Roving for SMC is compatible with unsaturated polyester, vinyl ester resin, delivering good dispersion after chopping, low fuzz, fast wet out and low static.

Product Features:

1) Good dispersion after chopping

2) Low fuzz

3) Fast wet out

4) Low static

2) Low fuzz

3) Fast wet out

4) Low static

|

Item

|

Linear Density

|

Features

|

End Use

|

|

BHSMC-01A

|

2400,4392

|

for general pigmentable

SMC product

|

truck parts, water tanks, door sheet and electrical parts

|

|

BHSMC-02A

|

2400,4392

|

high surface quality,

low combustible content

|

ceiling tiles, door sheet

|

|

BHSMC-03A

|

2400,4392

|

excellent hydrolysis resistance

|

bathtub

|

|

BHSMC-04A

|

2400,4392

|

high surface quality, high combustible content

|

bathroom equipment

|

|

BHSMC-05A

|

2400,4392

|

good choppability, excellent dispersion, low static

|

automotive bumper and headliner

|

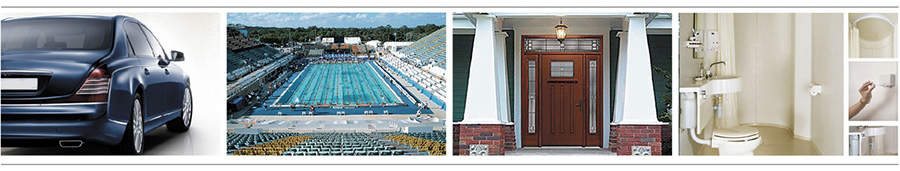

End-Use Markets

(Building and Construction/Chemical/Consumer Goods and Business Equipment /Automotive/Electrical and Electronics/Infrastructure/Sports and Leisure)

Write your message here and send it to us