-

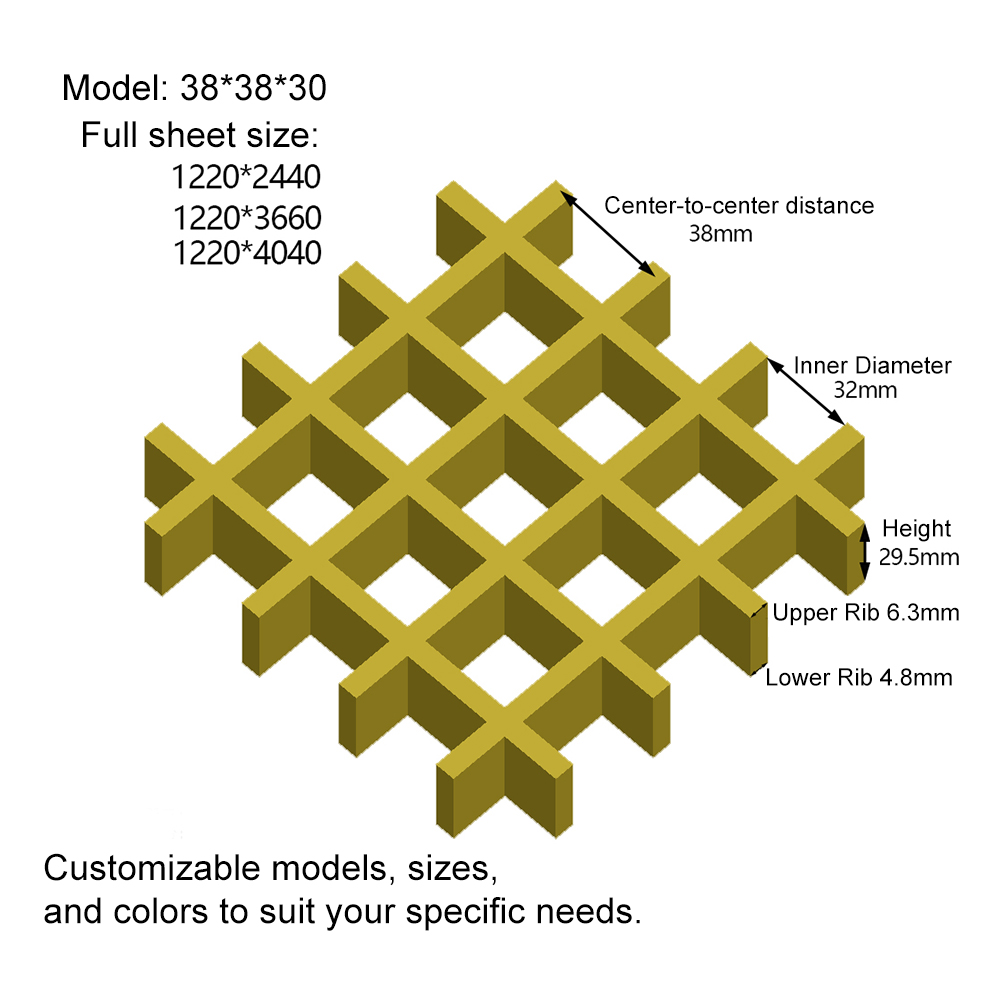

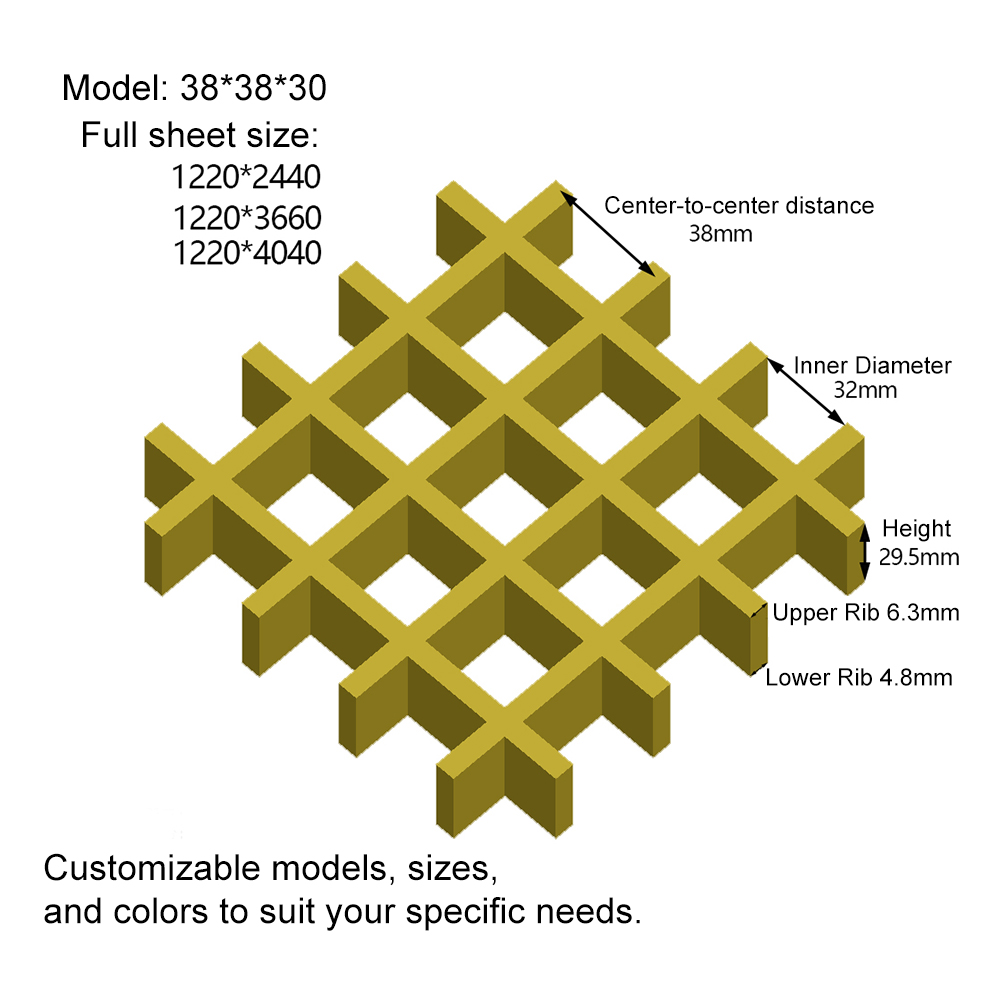

Pultruded FRP Grating

Pultruded fiberglass grating is manufactured using the pultrusion process. This technique involves continuously pulling a mixture of glass fibers and resin through a heated mold, forming profiles with high structural consistency and durability. This continuous production method ensures product uniformity and high quality. Compared to traditional manufacturing techniques, it allows for more precise control over fiber content and resin ratio, thereby optimizing the mechanical properties of the final product. -

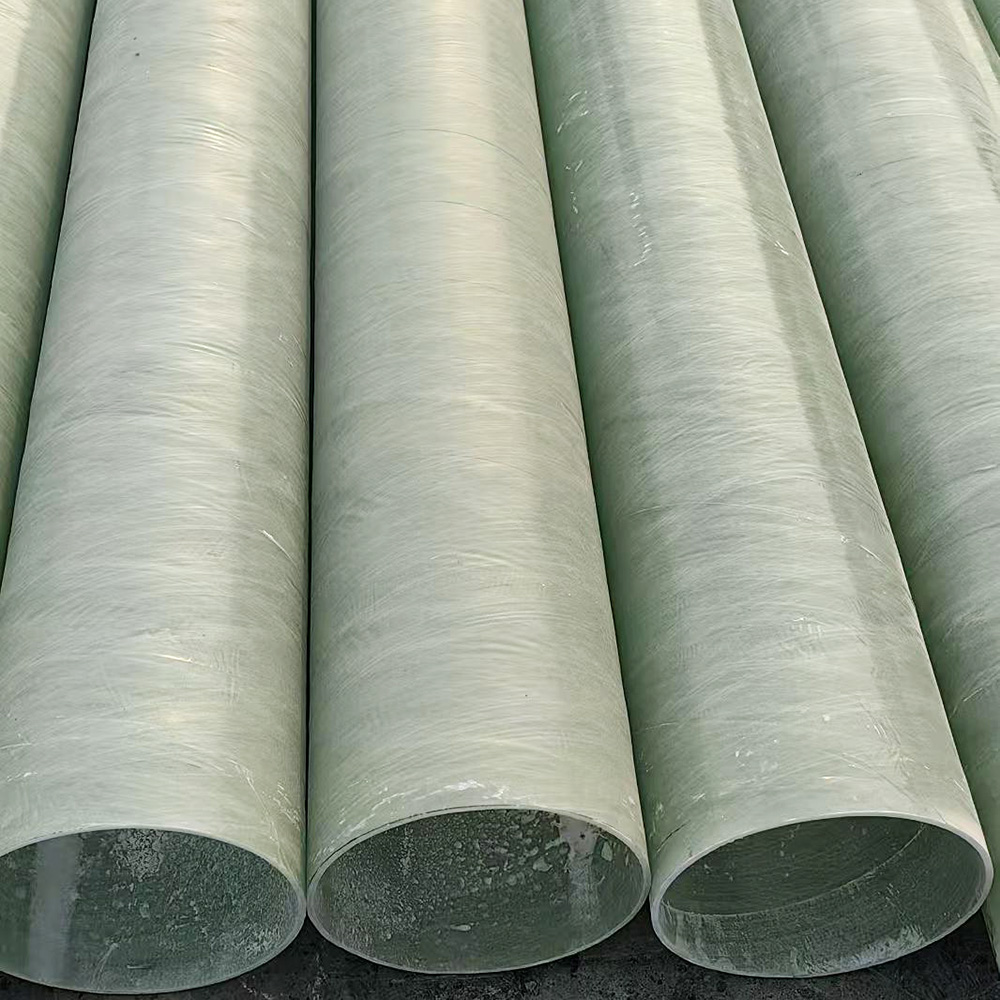

FRP Epoxy Pipe

FRP epoxy pipe is formally known as Glass Fiber Reinforced Epoxy (GRE) pipe. It is a high-performance composite material piping, manufactured using a filament winding or similar process, with high-strength glass fibers as the reinforcing material and epoxy resin as the matrix. Its core advantages include outstanding corrosion resistance (eliminating the need for protective coatings), light weight combined with high strength (simplifying installation and transport), extremely low thermal conductivity (providing thermal insulation and energy savings), and a smooth, non-scaling inner wall. These qualities make it an ideal replacement for traditional piping in sectors such as petroleum, chemical, marine engineering, electrical insulation, and water treatment. -

FRP Dampers

An FRP damper is a ventilation control product designed specifically for corrosive environments. Unlike traditional metal dampers, it is made from Fiberglass Reinforced Plastic (FRP), a material that perfectly combines the strength of fiberglass with the corrosion resistance of resin. This makes it an outstanding choice for handling air or flue gas containing corrosive chemical agents like acids, alkalis, and salts. -

FRP Flange

FRP (Fiberglass Reinforced Plastic) flanges are ring-shaped connectors used to join pipes, valves, pumps, or other equipment to create a complete piping system. They are made from a composite material consisting of glass fibers as the reinforcing material and synthetic resin as the matrix. -

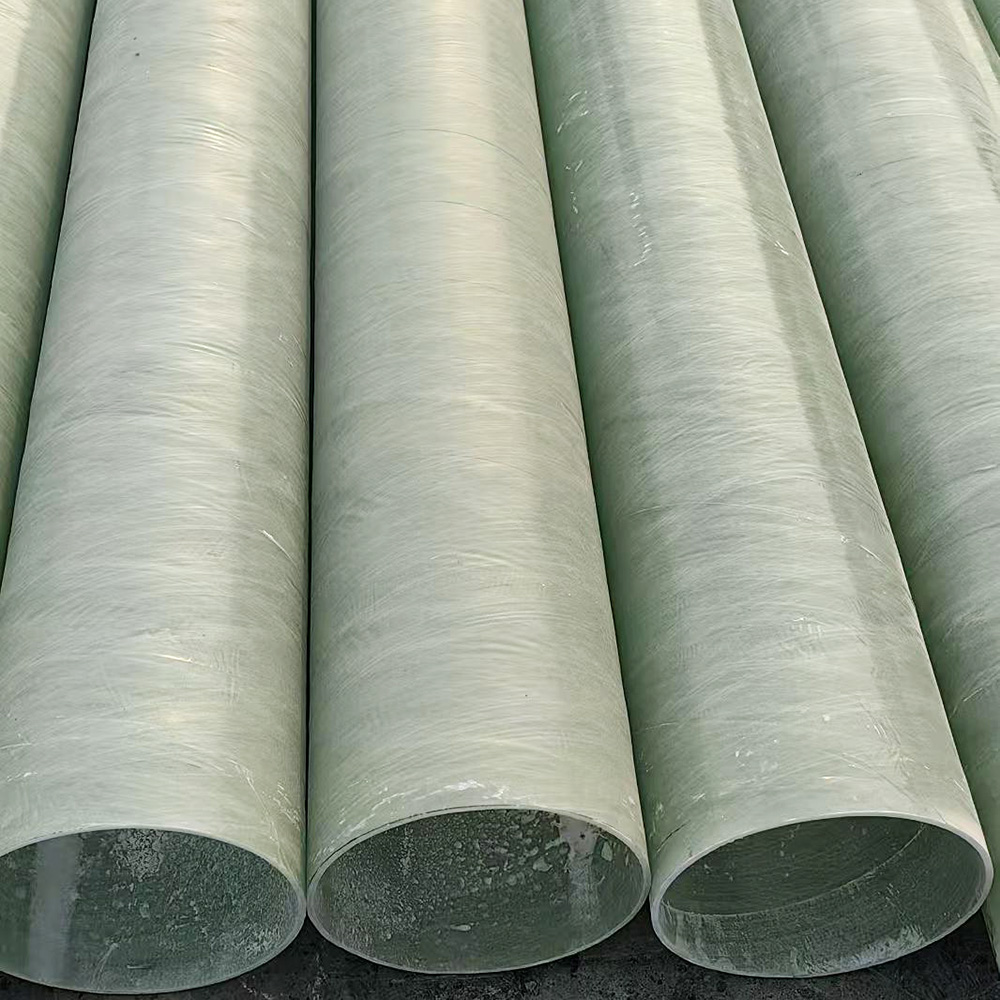

Fiberglass Reinforced Plastic (FRP) Winding Process Pipe

FRP pipe is a lightweight, high-strength, corrosion-resistant non-metallic pipe. It is the glass fiber with resin matrix wound layer by layer onto the rotating core mold according to the process requirements. The wall structure is reasonable and advanced, which can give full play to the role of the material and improve the rigidity under the premise of meeting the use of strength to ensure the stability and reliability of the product. -

Fiberglass Reinforced Polymer Bars

Fiberglass reinforcing bars for civil engineering are made of alkali-free glass fiber (E-Glass) untwisted roving with less than 1% alkali content or high-tensile glass fiber (S) untwisted roving and resin matrix (epoxy resin, vinyl resin), curing agent and other materials, composite by molding and curing process, referred to as GFRP bars. -

Glass Fiber Reinforced Composite Rebar

Glass fiber composite rebar is a kind of high performance material.which is formed by mixing fiber material and matrix material in acertain proportion. Because of the different kinds of resins used, theyare called polyester glass fiber reinforced plastics, epoxy glass fiberreinforced plastics and phenolic resin glass fiber reinforced plastics. -

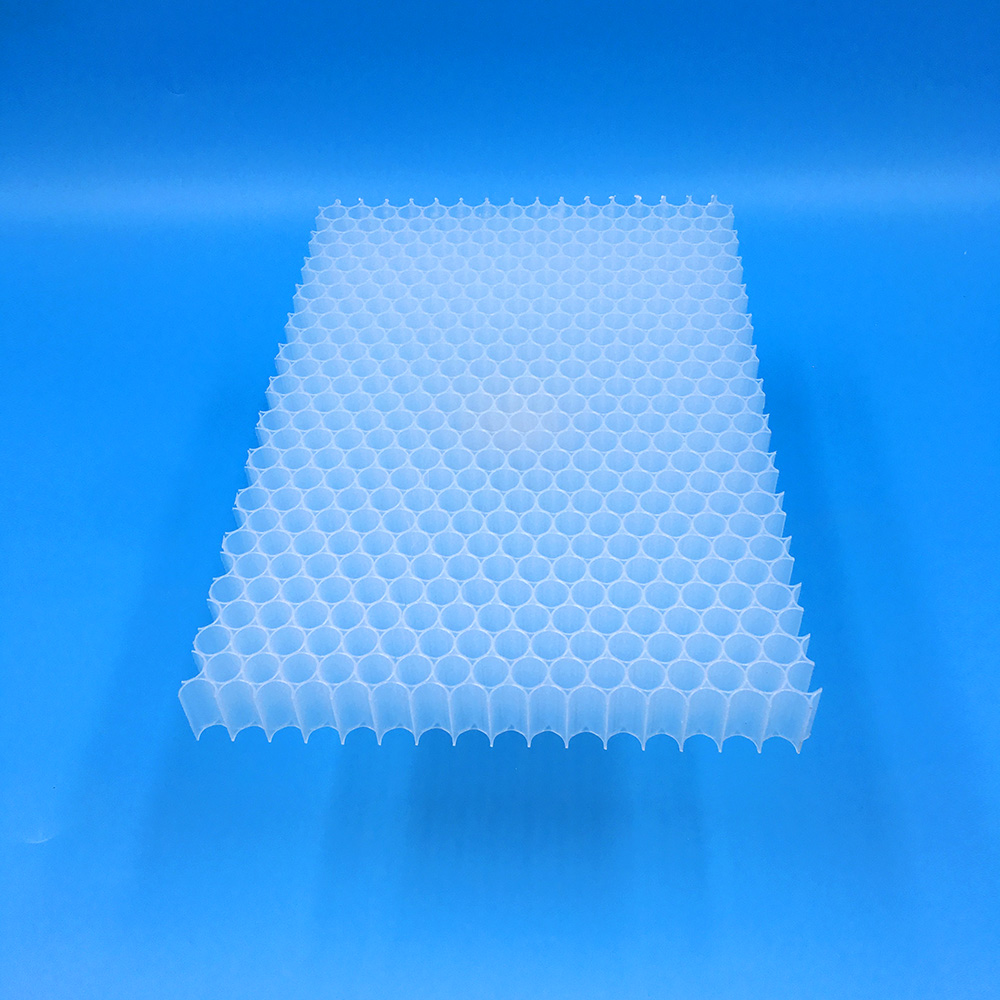

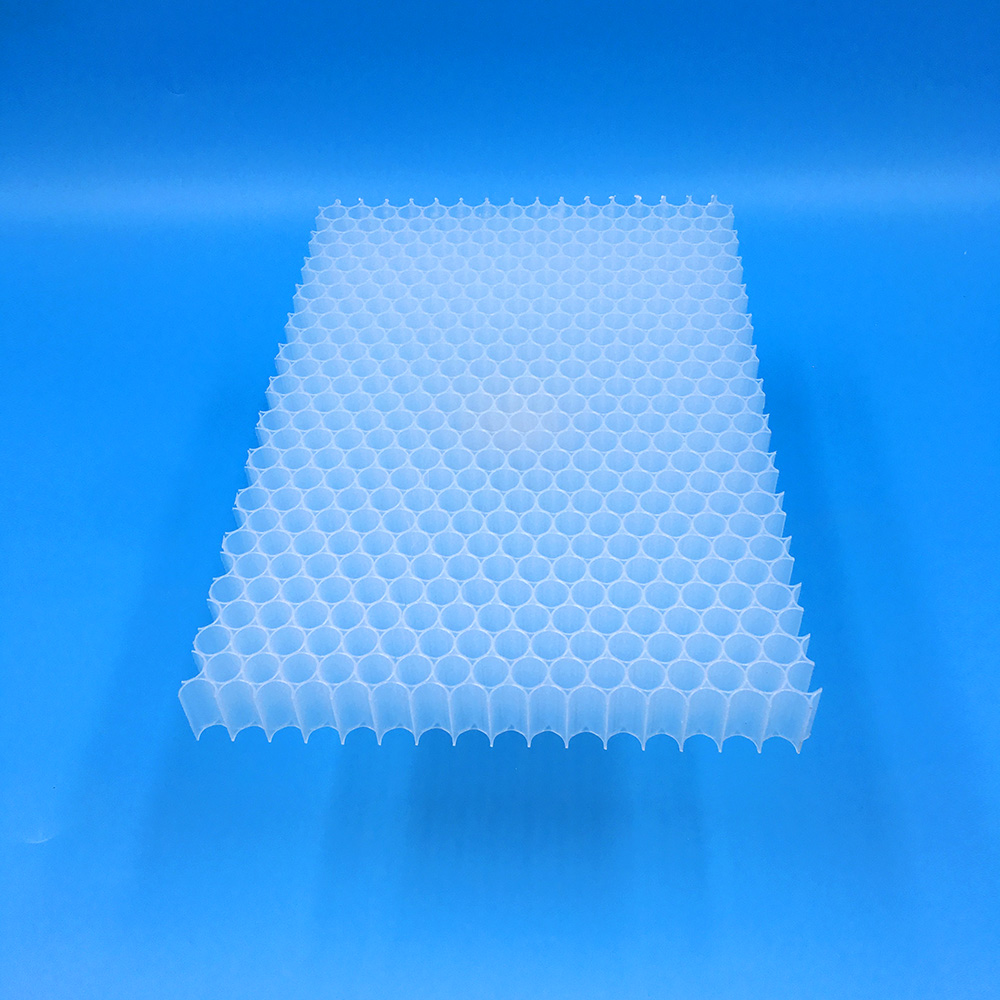

PP Honeycomb Core Material

Thermoplastic honeycomb core is a new type of structural material processed from PP/PC/PET and other materials according to the bionic principle of honeycomb. It has the characteristics of light weight and high strength, green environmental protection, waterproof and moisture-proof and corrosion-resistant, etc. -

Fiberglass Rock Bolt

GFRP(Glass Fiber Reinforced Polymer) rock bolts are specialized structural elements used in geotechnical and mining applications to reinforce and stabilize rock masses. They are made of high-strength glass fibers embedded in a polymer resin matrix, typically epoxy or vinyl ester. -

FRP foam sandwich panel

FRP foam sandwich panels are mainly used as building materials widely used in construction projects, common FRP foam panels are magnesium cement FRP bonded foam panels, epoxy resin FRP bonded foam panels, unsaturated polyester resin FRP bonded foam panels, etc. These FRP foam panels have the characteristics of good stiffness, light weight and good thermal insulation performance, etc. -

FRP Panel

FRP (also known as glass fiber reinforced plastic, abbreviated as GFRP or FRP) is a new functional material made of synthetic resin and glass fiber through a composite process. -

FRP sheet

It is made of thermosetting plastics and reinforced glass fiber, and its strength is greater than that of steel and aluminum.

The product will not produce deformation and fission at ultra-high temperature and low temperature, and its thermal conductivity is low. It is also resistant to aging, yellowing, corrosion, friction and easy to clean.