FRP Flange

Product Description

FRP (Fiberglass Reinforced Plastic) flanges are ring-shaped connectors used to join pipes, valves, pumps, or other equipment to create a complete piping system. They are made from a composite material consisting of glass fibers as the reinforcing material and synthetic resin as the matrix. They are manufactured using processes such as molding, hand lay-up, or filament winding.

Product Features

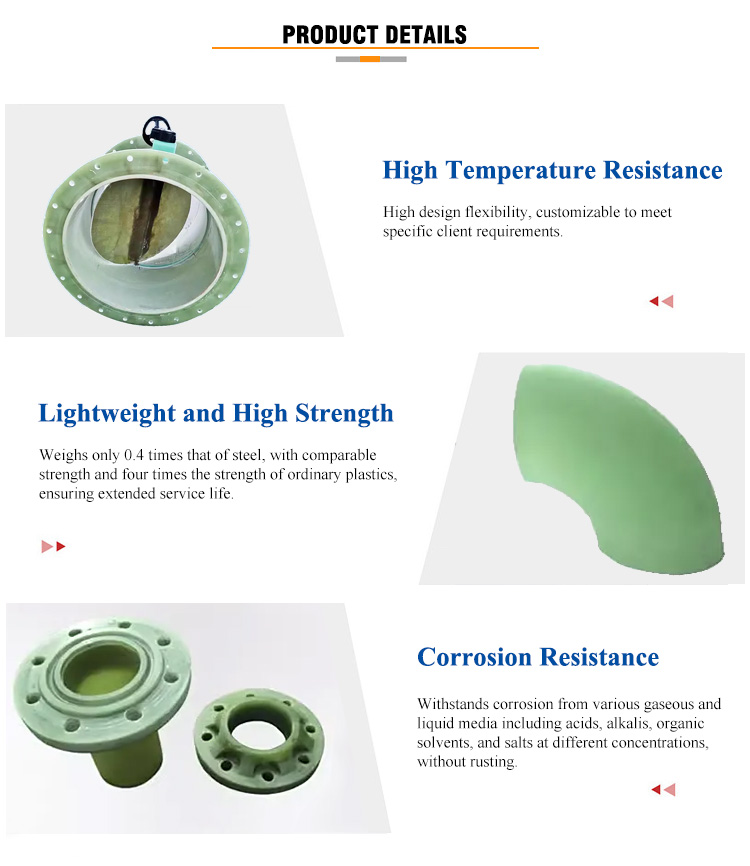

Thanks to their unique composition, FRP flanges offer significant advantages over traditional metal flanges:

- Excellent Corrosion Resistance: The most notable feature of FRP flanges is their ability to resist corrosion from various chemical media, including acids, alkalis, salts, and organic solvents. This makes them widely used in environments where corrosive fluids are transported, such as in the chemical, petroleum, metallurgy, power, pharmaceutical, and food industries.

- Lightweight and High Strength: The density of FRP is typically only 1/4 to 1/5 that of steel, yet its strength can be comparable. This makes them easier to transport and install, and it reduces the overall load on the piping system.

- Good Electrical Insulation: FRP is a non-conductive material, giving FRP flanges excellent electrical insulation properties. This is crucial in specific environments to prevent electrochemical corrosion.

- High Design Flexibility: By adjusting the resin formula and the arrangement of glass fibers, FRP flanges can be custom-made to meet specific requirements for temperature, pressure, and corrosion resistance.

- Low Maintenance Cost: FRP flanges do not rust or scale, leading to a long service life and significantly reducing maintenance and replacement costs.

Product Type

Based on their manufacturing process and structural form, FRP flanges can be categorized into several types:

- One-Piece (Integral) Flange: This type is formed as a single unit with the pipe body, offering a tight structure suitable for low to medium-pressure applications.

- Loose Flange (Lap Joint Flange): Consists of a loose, freely rotating flange ring and a fixed stub end on the pipe. This design facilitates installation, especially in multi-point connections.

- Blind Flange (Blank Flange/End Cap): Used to seal off the end of a pipe, typically for pipeline system inspection or to reserve an interface.

- Socket Flange: The pipe is inserted into the flange’s inner cavity and connected securely through adhesive bonding or winding processes, ensuring good sealing performance.

Product Specifications

|

DN |

P=0.6MPa |

P=1.0MPa |

P=1.6MPa |

|||

|

S |

L |

S |

L |

S |

L |

|

|

10 |

12 |

100 |

15 |

100 |

15 |

100 |

|

15 |

12 |

100 |

15 |

100 |

15 |

100 |

|

20 |

12 |

100 |

15 |

100 |

18 |

100 |

|

25 |

12 |

100 |

18 |

100 |

20 |

100 |

|

32 |

15 |

100 |

18 |

100 |

22 |

100 |

|

40 |

15 |

100 |

20 |

100 |

25 |

100 |

|

50 |

15 |

100 |

22 |

100 |

25 |

150 |

|

65 |

18 |

100 |

25 |

150 |

30 |

160 |

|

80 |

18 |

150 |

28 |

160 |

30 |

200 |

|

100 |

20 |

150 |

28 |

180 |

35 |

250 |

|

125 |

22 |

200 |

30 |

230 |

35 |

300 |

|

150 |

25 |

200 |

32 |

280 |

42 |

370 |

|

200 |

28 |

220 |

35 |

360 |

52 |

500 |

|

250 |

30 |

280 |

45 |

420 |

56 |

620 |

|

300 |

40 |

300 |

52 |

500 |

|

|

|

350 |

45 |

400 |

60 |

570 |

|

|

|

400 |

50 |

420 |

|

|

|

|

|

450 |

50 |

480 |

|

|

|

|

|

500 |

50 |

540 |

|

|

|

|

|

600 |

50 |

640 |

|

|

|

|

For larger apertures or custom specifications, please contact me for customization.

Product Applications

Due to their exceptional corrosion resistance and lightweight strength, FRP flanges are widely used in:

- Chemical Industry: For pipelines transporting corrosive chemicals like acids, alkalis, and salts.

- Environmental Engineering: In wastewater treatment and flue gas desulfurization equipment.

- Power Industry: For cooling water and desulfurization/denitrification systems in power plants.

- Marine Engineering: In seawater desalination and ship piping systems.

- Food and Pharmaceutical Industries: For production lines requiring high material purity.