FRP Dampers

Product Description

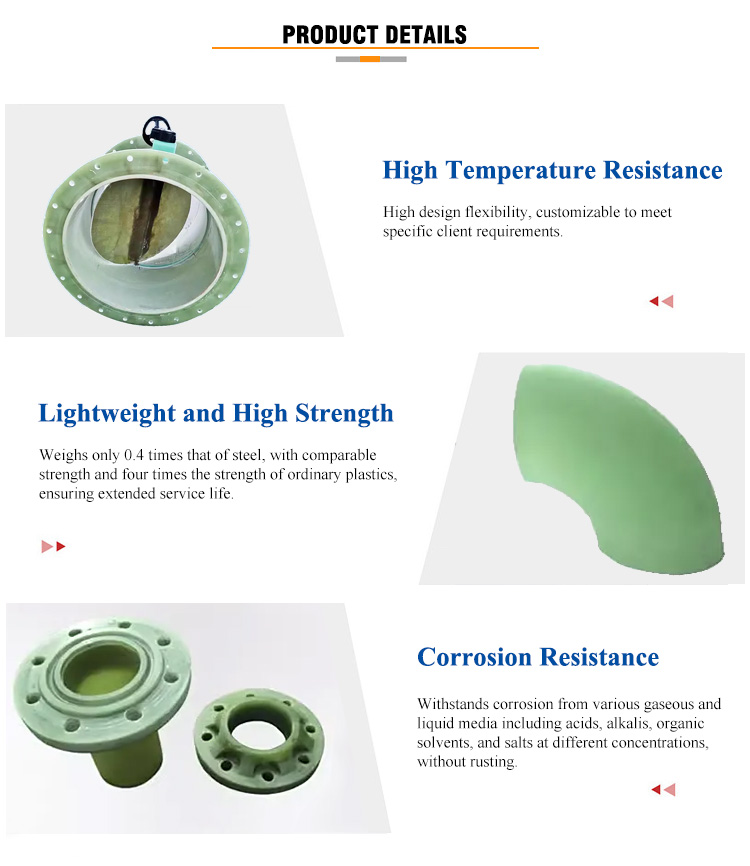

An FRP damper is a ventilation control product designed specifically for corrosive environments. Unlike traditional metal dampers, it is made from Fiberglass Reinforced Plastic (FRP), a material that perfectly combines the strength of fiberglass with the corrosion resistance of resin. This makes it an outstanding choice for handling air or flue gas containing corrosive chemical agents like acids, alkalis, and salts.

Product Features

- Excellent Corrosion Resistance: This is the core advantage of FRP dampers. They effectively resist a wide range of corrosive gases and liquids, ensuring long-term stable operation in harsh environments and significantly extending their service life.

- Lightweight and High Strength: FRP material has low density and light weight, making it easy to transport and install. At the same time, its strength is comparable to some metals, allowing it to withstand certain wind pressures and mechanical stresses.

- Superior Sealing Performance: The damper’s interior typically uses corrosion-resistant sealing materials like EPDM, silicone, or fluoroelastomer to ensure excellent airtightness when closed, effectively preventing gas leakage.

- Flexible Customization: Dampers can be customized with different diameters, shapes, and actuation methods—such as manual, electric, or pneumatic—to meet various complex engineering requirements.

- Low Maintenance Cost: Due to their corrosion resistance, FRP dampers are not prone to rust or damage, which reduces daily maintenance and lowers long-term operating costs.

Product Specifications

|

Model |

Dimensions |

Weight |

|||

|

High |

Outer diameter |

Flange width |

Flange thickness |

||

|

DN100 |

150mm |

210mm |

55mm |

10mm |

2.5KG |

|

DN150 |

150mm |

265mm |

58mm |

10mm |

3.7KG |

|

DN200 |

200mm |

320mm |

60mm |

10mm |

4.7KG |

|

DN250 |

250mm |

375mm |

63mm |

10mm |

6KG |

|

DN300 |

300mm |

440mm |

70mm |

10mm |

8KG |

|

DN400 |

300mm |

540mm |

70mm |

10mm |

10KG |

|

DN500 |

300mm |

645mm |

73mm |

10mm |

13KG |

Product Applications

FRP dampers are widely used in industrial fields with high anti-corrosion requirements, such as:

- Acid-base waste gas treatment systems in the chemical, pharmaceutical, and metallurgy industries.

- Ventilation and exhaust systems in the electroplating and dyeing industries.

- Areas with corrosive gas production, such as municipal wastewater treatment plants and waste-to-energy power plants.