Fiberglass Assembled Roving Direct Roving 600tex -1200tex-2400tex -4800tex for Spray up/ Injection / Pipe / Panel /BMC/ SMC/ Lfi /Ltf / Pultrusion

Assembled rovings are produced by combining a certain number of parallel strands without twist. The surface of strands is coated with a silane-based size which imparts a specifica application property to the product.

Assembled rovings are compatible with polyester, vinyl ester, phenolic and exoxy resins.

Assembled rovings are specially designed as reinforcement for FRP pipes. pressure vessels, gratings, profiles, panles and sealing materials. and when convertrf into woven rovings, for boats and chemical storage tanks.

Product Features

◎ Excellent anti-static property

◎ Good dispersion

◎ Good strand integrity, no fuzz and loose fiber

◎ High mechanical strength,

Identification

|

Example |

ER14-2400-01A |

|

Type of Glass |

E |

|

Size Code |

BHSMC-01A |

|

Linear Density,tex |

2400,4392 |

|

Filament Diameter,μm |

14 |

Technical Parameters

|

Linear Density (%) |

Moisture Content (%) |

Size Content (%) |

Breakage Strength (N/Tex) |

|

ISO1889 |

ISO3344 |

ISO1887 |

IS03375 |

|

±5 |

≤0.10 |

1.25±0.15 |

160±20 |

Storage

Unless otherwise specified, the fiberglass products should be in dry, cool and moisture-proof area. The room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65%. It is best if the price is used within 12 months after production date. The fiberglass products should remain in their original packaging until just prior to user.

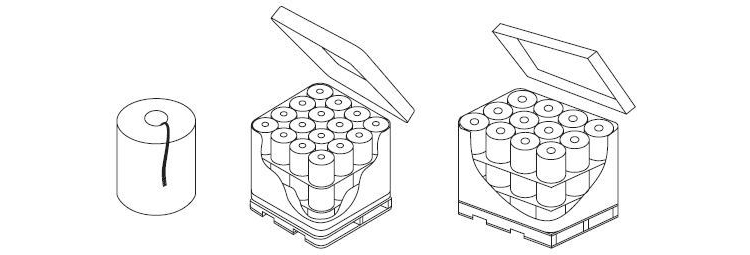

To ensure safety and avoid damage to the product, the pallets not be stacked more than three layers high. When the pallets are stacked in 2 or 3 layers, special care should be taken to correctly and smoothly move the top pallet.

Packaging

The product can be packed on pallet or in small cardboard boxes.

| Package height mm (in) | 260(10) | 260(10) |

| Package inside diameter mm(in) | 160(6.3) | 160(6.3) |

| Package outside diameter mm(in) | 275(10.6) | 310(12.2) |

| Package Weight kg(lb) | 15.6(34.4) | 22(48.5) |

| Number of layers | 3 | 4 | 3 | 4 |

| Number of doffs per layer | 16 | 12 | ||

| Number of doffs per pallet | 48 | 64 | 46 | 48 |

| Net Weight per pallet kg(lb) | 816(1798.9) | 1088(2396.6) | 792(1764) | 1056(2328) |

| Pallet Length mm(in) | 1120(44) | 1270(50) | ||

| Pallet Width mm(in) | 1120(44) | 960(378) | ||

| Pallet height mm(in) | 940(37) | 1180(46.5) | 940(37) | 1180(46.5) |