Fibeglass Reinforced Thermoplastic Assembeld Roving with PBT/PET, ABS Resin for FRP Parts

Assembled Roving for thermoplastic is coated with a silane-based sizing compatible with multiple resin systems such as PP、AS/ABS,especially reinforcing PA for good hydrolysis resistant.

Features:

- Excellent mechanical properties and hydrolysis resistant for PA

- Shiny surface of the composite product without fiber revealed.

- Smooth and low fuzz for good working atmosphere.

- Uniform liner density for final products with consistent glass content.

- Compatible with multiple resin system such as PP、AS/ABS.

| Identification | |

| Type of Glass |

E |

| Assembled Roving |

R |

| Filament Diameter, μm |

11,13,14 |

| Linear Density, tex |

2000 |

| Technical Parameters | |||

|

Linear Density (%) |

Moisture Content (%) |

Size Content (%) |

Stiffness (mm) |

|

ISO 1889 |

ISO 3344 |

ISO 1887 |

ISO 3375 |

|

±5 |

≤0.10 |

0.90±0.15 |

130±20 |

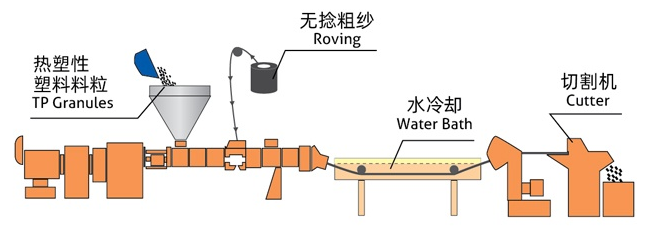

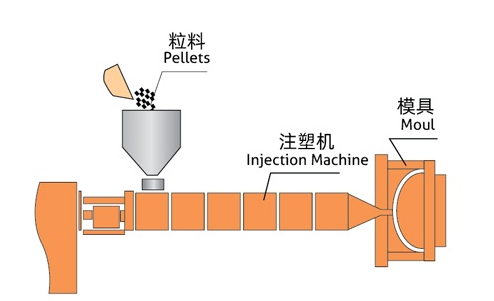

Extrusion and Injection Processes

The reinforcements ( glass fiber roving ) and thermoplastic resin are mixed in an extruder After cooling , they are chopped into reinforced thermoplastic pellets . The pellets are fed into an injection molding machine to form finished parts.

Application

E-glass Assembled Roving For Thermoplastics are typically designed for twin-screw extrusion process to manufacture thermoplastic granules. Key applications include railway track fastening pieces、automotive parts,elactrical & electronic applications.