Which costs more, fiberglass or carbon fiber

When it comes to cost, fiberglass typically has a lower cost compared to carbon fiber. Below is a detailed analysis of the cost difference between the two:

Raw material cost

Fiberglass: the raw material of glass fiber is mainly silicate minerals, such as quartz sand, chlorite, limestone, etc. These raw materials are relatively abundant and the price is relatively stable, so the raw material cost of glass fiber is relatively low.

Carbon fiber: the raw materials of carbon fiber are mainly polymer organic compounds and petroleum refinery, after a series of complex chemical reactions and high temperature treatment to be made. This process requires the consumption of a large amount of energy and raw materials, and the preciousness and scarcity of raw materials also led to the increase in the cost of carbon fiber raw materials.

Production process cost

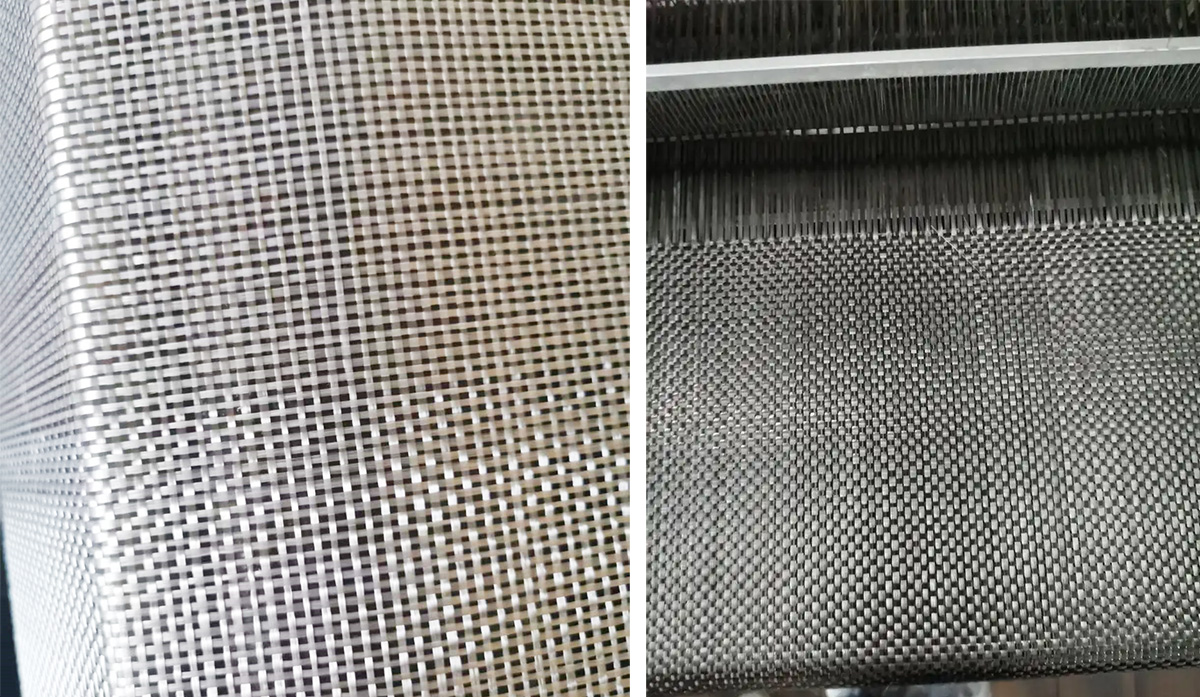

Fiberglass: The production process of glass fiber is relatively simple, mainly including raw material preparation, melting silk, drawing, twisting, weaving and other steps. These steps are relatively easy to control, and equipment investment and maintenance costs are low.

Carbon Fiber: The production process of carbon fiber is relatively complex, requiring a number of high-temperature processing steps such as raw material preparation, pre-oxidation, carbonization and graphitization. These steps require high-precision equipment and complex process control, resulting in higher production costs.

Market Price

Glass Fiber: The market price of glass fiber is usually low due to the low cost of raw materials and simple production process. In addition, the production volume of glass fiber is also relatively large and the market is highly competitive, which further reduces its market price.

Carbon Fiber: Carbon Fiber has a high raw material cost, complex production process, and relatively small market demand (mainly used in high-end fields), so its market price is usually higher.

In summary, glass fiber has a clear advantage over carbon fiber in terms of cost. However, when choosing a material, in addition to cost, other factors need to be considered, such as strength, weight, corrosion resistance, processing performance and so on. It is crucial to choose the most suitable material according to specific application scenarios and needs.

Post time: Apr-28-2025