With the rapid development in the field of engineered glass fiber reinforced plastics, phenolic resin-based materials have been widely applied across various industries. This is due to their unique quality, high mechanical strength, and excellent performance. One of the most significant representative materials is phenolic glass fiber resin material.

Phenolic glass fiber, among the earliest industrialized synthetic resins, is typically a polycondensate formed by the polymerization of phenols and aldehydes in the presence of an alkaline catalyst. Certain additives are then introduced to cross-link the macromolecular structure, transforming it into an insoluble and infusible three-dimensional macromolecular structure, thereby becoming a typical thermosetting polymer material. Phenolic resins are highly valued for their outstanding properties, including excellent flame retardancy, dimensional stability, and good mechanical strength. These attributes have propelled extensive research and application of phenolic glass fiber resin materials.

As industrial economies rapidly advance, increasing demands are placed on the performance of phenolic glass fiber materials. Consequently, high-strength and heat-resistant modified phenolic glass fibers are being extensively developed and utilized. Glass fiber reinforced modified phenolic resin (FX-501) is currently one of the most successful modified phenolic glass fiber resin materials. It is a new type of modified and reinforced phenolic material created by incorporating glass fibers into the original resin matrix through mixing.

Mechanical Properties and Constituent Roles

Phenolic glass fiber resin is often chosen as a matrix for wear-resistant, tensile, and compressive materials due to its good tensile strength, solvent resistance, and excellent mechanical properties like flame retardancy. The matrix material primarily functions as a binder, organically connecting all components. Glass fibers serve as the main load-bearing units in wear-resistant materials, providing load-carrying capacity, and their superior performance directly impacts the reinforcing effect on the matrix.

The role of the matrix material is to firmly bond other components of the tensile material, ensuring that loads are uniformly transferred, distributed, and allocated to various glass fibers. This imparts a certain strength and toughness to the material. Common fibers, including glass fibers, organic fibers, steel fibers, and mineral fibers, play a role in adjusting the tensile strength of the material.

Load Bearing in Composites and Impact of Fiber Content

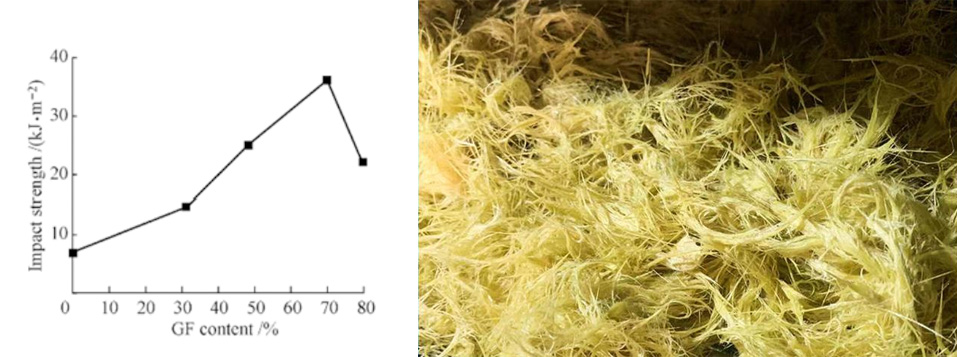

In phenolic glass fiber composite material systems, both the fibers and the matrix resin bear the load, with glass fibers remaining the primary load-bearer. When phenolic glass fiber composites are subjected to bending or compression stress, the stress is uniformly transferred from the matrix resin to individual glass fibers through the interface, effectively dispersing the borne force. This process improves the mechanical properties of the composite material. Therefore, an appropriate increase in glass fiber content can enhance the strength of phenolic glass fiber composites.

Experimental results indicate the following:

- Phenolic glass fiber composites with 20% glass fiber content exhibit uneven fiber distribution, with some areas even lacking fibers.

- Phenolic glass fiber composites with 50% glass fiber content show uniform fiber distribution, irregular fracture surfaces, and no significant signs of extensive fiber pull-out. This suggests that the glass fibers can collectively bear the load, resulting in higher flexural strength.

- When the glass fiber content is 70%, the excessive fiber content leads to a relatively low matrix resin content. This can cause “resin-poor” phenomena in some areas, impeding stress transfer and creating localized stress concentrations. Consequently, the overall mechanical properties of the phenolic glass fiber composite material tend to decrease.

From these findings, the maximum allowable addition of glass fiber in phenolic glass fiber composites is 50%.

Performance Enhancement and Influencing Factors

From the numerical data, phenolic glass fiber composites containing 50% glass fiber exhibit approximately three times the flexural strength and four times the compressive strength compared to pure phenolic resin. Additionally, other factors influencing the strength of phenolic glass fiber reinforced plastics include the length of the glass fibers and their orientation.

Post time: Jun-18-2025