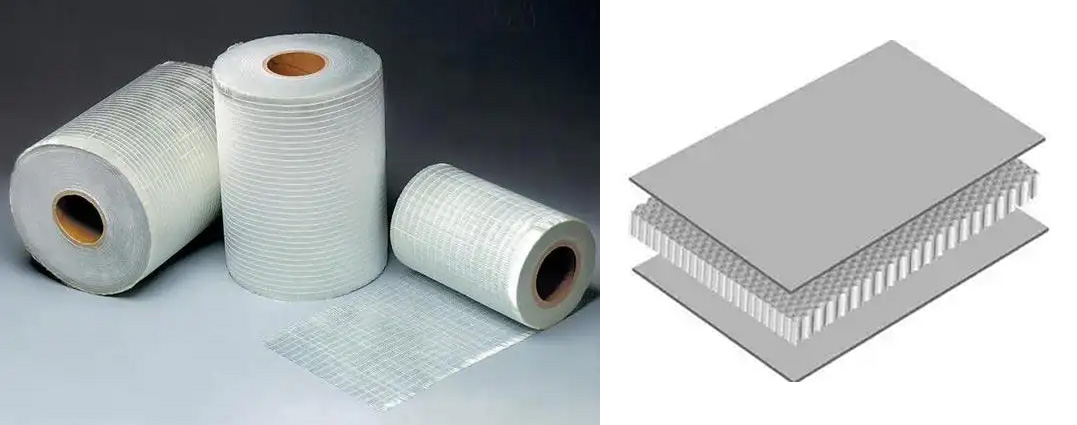

In a composite material, the performance of fiberglass as a key reinforcing component largely depends on the interfacial bonding ability between the fiber and the matrix. The strength of this interfacial bond determines the stress transfer capability when the glass fiber is under load, as well as the stability of the glass fiber when its strength is high. Generally, the interfacial bonding between fiberglass and the matrix material is very weak, which restricts the application of fiberglass in high-performance composite materials. Therefore, using a sizing agent coating process to optimize the interfacial structure and strengthen the interfacial bonding is a key method to improve the performance of glass fiber composites.

A sizing agent forms a molecular layer on the surface of the fiberglass, which can effectively reduce the interfacial tension, making the fiberglass surface more hydrophilic or oleophilic to improve compatibility with the matrix. For example, using a sizing agent containing chemically active groups can create chemical bonds with the fiberglass surface, further enhancing the interfacial bond strength.

Research has shown that nano-level sizing agents can coat the fiberglass surface more uniformly and strengthen the mechanical and chemical bonding between the fiber and the matrix, thereby effectively improving the mechanical properties of the fiber. At the same time, a suitable sizing agent formulation can adjust the surface energy of the fiber and change the wettability of the fiberglass, leading to a strong interfacial adhesion between the fiber and different matrix materials.

Different coating processes also have a significant effect on improving the interfacial bond strength. For example, plasma-assisted coating can use ionized gas to treat the glass fiber surface, removing organic matter and impurities, increasing surface activity, and thus improving the bonding of the sizing agent to the fiber surface.

The matrix material itself also plays a crucial role in interfacial bonding. Developing new matrix formulations that have a stronger chemical affinity for the treated glass fibers can lead to significant improvements. For instance, matrices with a high concentration of reactive groups can form more robust covalent bonds with the sizing agent on the fiber surface. Furthermore, modifying the viscosity and flow properties of the matrix material can ensure better impregnation of the fiber bundle, minimizing voids and defects at the interface, which are a common source of weakness.

The manufacturing process itself can be optimized to improve interfacial bonding. Techniques like vacuum infusion or resin transfer molding (RTM) can ensure a more uniform and complete wetting of the glass fibers by the matrix, eliminating air pockets that can weaken the bond. Additionally, applying external pressure or using controlled temperature cycles during curing can promote a more intimate contact between the fiber and the matrix, leading to a higher degree of cross-linking and a stronger interface.

Improving the interfacial bonding strength of glass fiber composites is a critical area of research with significant practical applications. While the use of sizing agents and various coating processes is a cornerstone of this effort, there are several other avenues being explored to further enhance performance.

Post time: Sep-04-2025