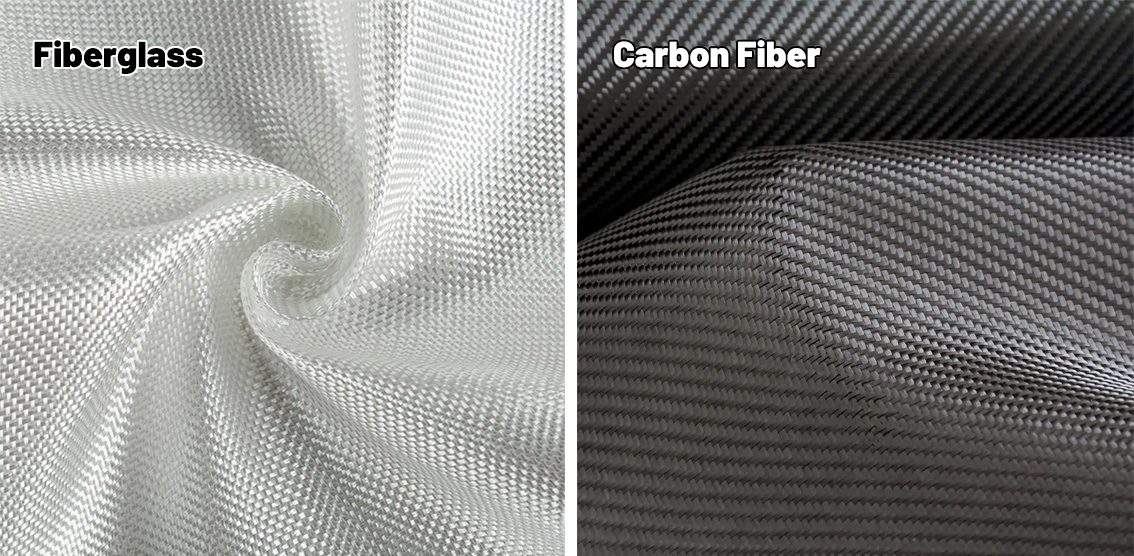

For those just getting into composites, you’ve probably hit that big question: “When making stuff or testing, do I go with fiberglass or carbon fiber?” You might’ve heard carbon fiber’s the fancy option—super strong like steel but way lighter. Then there’s folks saying fiberglass gives you more bang for your buck and is easier for beginners to start with. Truth is, there’s no single “better” choice—just what fits best. Think of fiberglass as the practical, wallet-friendly pick, and carbon fiber as the high-performance premium route. Pick right, and you could cut costs in half; get it wrong, and your project might totally fall apart.

So today, let’s break down the differences between them—looking at properties, cost, how they’re made, and where they work best—so even if you’re new to this, you can figure it out quick and easy!

1. How big is the cost gap?——Carbon fiber is 5~10 times that of glass fiber

This is the most intuitive feeling for novices:

①Glass fiber: Ordinary E-glass fiber cloth only costs 20~50 yuan per square meter, and glass fiber chopped yarn is 15~30 yuan per kilogram. There is no pressure for student experiments and small batch production.

② Carbon fiber: T300 carbon fiber cloth is 200~500 yuan per square meter, carbon fiber chopped yarn is 150~200 yuan per kilogram, and high-end models such as T700 have higher prices, which are only suitable for high-end projects that are not sensitive to cost.

Conclusion: If the budget is limited and the performance requirements are not extreme, glass fiber is the first choice; if the pursuit of lightweight, high strength, and sufficient budget, then consider carbon fiber.

2. Processing difficulty: For beginners, fiberglass is more user-friendly to start with.

The processing characteristics of the two fibers are significantly different, which directly affects the efficiency of experiments/production.

①Glass fiber: It is relatively soft and can be cut with ordinary scissors. It has good resin impregnation properties, especially with epoxy resin. It is easy for beginners to handle. Even if the layering is not perfect, it has little impact on the final performance.

② Carbon fiber: It is hard and brittle. Ordinary scissors cannot cut it. Special carbon fiber scissors or grinding wheels are needed for cutting, and black dust will be produced during cutting (harmful if inhaled). When impregnating with resin, it needs to be done quickly; otherwise, “dry areas” (fibers not fully impregnated with resin) may occur, affecting the strength.

Conclusion: For beginners undertaking their first composite material project, it is advisable to start with fiberglass for practice; after gaining some experience, they can then try carbon fiber.

3. Performance adaptation: When do I have to choose carbon fiber?

Although glass fiber is cost-effective, only carbon fiber can meet some scenarios.

①Glass fiber and carbon fiber are not the relationship between “who crushes who”, but a complementary choice between “cost-effective” and “high performance”.:

Glass fiber is a “novice-friendly” material, which is cheap, easy to process, and widely used. It is suitable for most civilian scenarios and entry-level experiments;

② Carbon fiber is a “high-end performance” material, which is lightweight, high-strength, and high-rigidity. It is suitable for high-end scenarios with extreme performance requirements.

Novices don’t need to blindly pursue carbon fiber. First, they can familiarize themselves with the process of glass fiber, and then upgrade the materials according to the needs of the project, which can not only save costs, but also improve the success rate.If your project has special requirements (such as extreme environments and special loads), please contact us to discuss the most suitable material options!

Need to be extremely lightweight: for example, drone fuselage, model airplane wings, and racing parts, the carbon fiber density is only 66% of that of glass fiber. At the same strength, the weight of the components can be reduced by 30% to 50%.%;

High rigidity is required: such as precision instrument brackets, bridge models, and main beams of wind power blades, the elastic modulus of carbon fiber is 3 times that of glass fiber, which can reduce component deformation.;

High temperature resistance is required: for example, the hot-end components of aviation engines and the protective layers of high-temperature equipment, the long-term temperature resistance of carbon fiber far exceeds that of glass fiber.

And the advantages of glass fiber.

Ordinary structural parts: such as glass fiber reinforced plastic flower pots, billboards, and truck compartment partitions, which have low requirements for weight and rigidity.;

Corrosion-resistant scenarios: such as chemical equipment housings, sewage treatment tanks, glass fiber has better acid and alkali resistance;

Insulation scenarios: such as electronic equipment housings, cable protective sleeves, glass fiber insulation is good to avoid the risk of conductivity.

Post time: Feb-06-2026