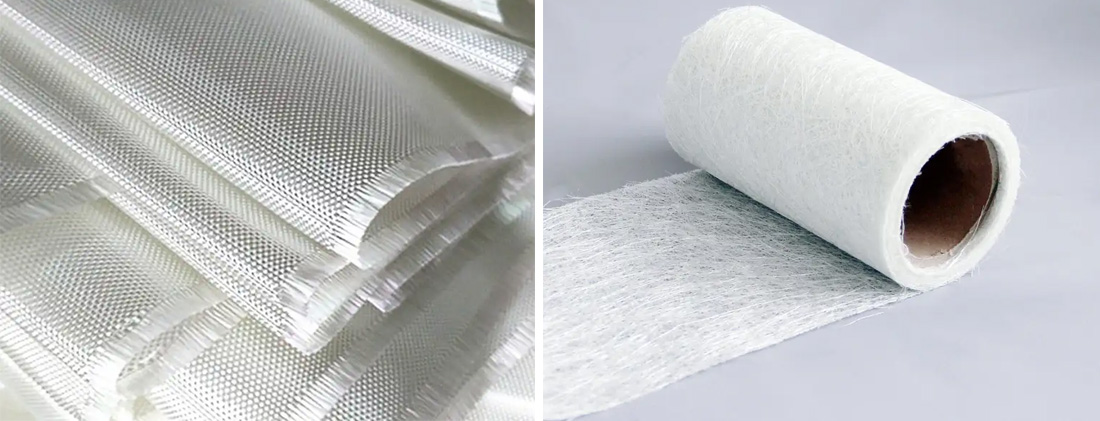

Glass Fiber Mats

1.Chopped Strand Mat (CSM)Glass fiber roving (sometimes also continuous roving) is cut into 50mm lengths, randomly but uniformly laid on a conveyor mesh belt. An emulsion binder is then applied, or a powder binder is dusted on, and the material is heated and cured to form the chopped strand mat. CSM is mainly used in hand lay-up, continuous panel making, matched die molding, and SMC (Sheet Molding Compound) processes. Quality requirements for CSM include:

- Uniform area weight across the width.

- Uniform distribution of chopped strands on the mat surface with no large voids, and uniform binder distribution.

- Moderate dry mat strength.

- Excellent resin wetting and penetration properties.

2.Continuous Filament Mat (CFM) Continuous glass fiber filaments formed during the drawing process or unwound from roving packages are laid down in a figure-eight pattern on a continuously moving mesh belt and bonded with a powder binder. Since the fibers in CFM are continuous, they provide better reinforcement to composite materials than CSM. It is mainly used in pultrusion, RTM (Resin Transfer Molding), pressure bag molding, and GMT (Glass Mat Reinforced Thermoplastics) processes.

3.Surfacing Mat FRP (Fiber Reinforced Plastic) products usually require a resin-rich surface layer, which is typically achieved using medium-alkali glass (C-glass) surfacing mat. As this mat is made from C-glass, it provides the FRP with chemical resistance, especially acid resistance. Additionally, due to its thinness and finer fiber diameter, it can absorb more resin to form a resin-rich layer, covering the texture of glass fiber reinforcing materials (like woven roving) and serving as a surface finish.

4.Needled Mat Can be categorized into Chopped Fiber Needled Mat and Continuous Filament Needled Mat.

- Chopped Fiber Needled Mat is made by chopping glass fiber roving into 50mm lengths, randomly laying them on a substrate previously placed on a conveyor belt, and then needling it with barbed needles. The needles push the chopped fibers into the substrate, and the barbs also bring some fibers up, forming a three-dimensional structure. The substrate used can be a loosely woven fabric of glass or other fibers. This type of needled mat has a felt-like texture. Its main uses include thermal and acoustic insulation materials, lining materials, and filtration materials. It can also be used in FRP production, but the resulting FRP has lower strength and limited application scope.

- Continuous Filament Needled Mat is made by randomly throwing continuous glass fiber filaments onto a continuous mesh belt using a filament spreading device, followed by needling with a needle board to form a mat with an interwoven three-dimensional fiber structure. This mat is primarily used in the production of glass fiber reinforced thermoplastic stampable sheets.

5.Stitched Mat Chopped glass fibers ranging from 50mm up to 60cm in length can be stitched together with a stitching machine to form a chopped fiber mat or a long fiber mat. The former can replace traditional binder-bonded CSM in some applications, and the latter can, to some extent, replace CFM. Their common advantages are the absence of binders, avoiding pollution during production, good resin impregnation performance, and lower cost.

Glass Fiber Fabrics

The following introduces various glass fiber fabrics woven from glass fiber yarns.

1.Glass Cloth Glass cloth produced in China is divided into alkali-free (E-glass) and medium-alkali (C-glass) types; most foreign production uses E-GLASS alkali-free glass cloth. Glass cloth is primarily used to produce various electrical insulating laminates, printed circuit boards, vehicle bodies, storage tanks, boats, molds, etc. Medium-alkali glass cloth is mainly used to produce plastic-coated packaging fabrics and for corrosion-resistant applications. The characteristics of the fabric are determined by fiber properties, warp and weft density, yarn structure, and weave pattern. Warp and weft density are determined by the yarn structure and weave pattern. The combination of warp and weft density and yarn structure determines the physical properties of the fabric, such as weight, thickness, and breaking strength. There are five basic weave patterns: plain (similar to woven roving), twill (generally±45°), satin (similar to unidirectional fabric), leno (main weave for glass fiber mesh), and matts (similar to oxford fabric).

2.Glass Fiber Tape Divided into woven-edge tape (selvage edge) and non-woven-edge tape (frayed edge). The main weave pattern is plain. Alkali-free glass fiber tape is often used to manufacture electrical equipment components requiring high strength and good dielectric properties.

3.Glass Fiber Unidirectional Fabric

- Unidirectional Warp Fabric is a four-harness broken satin or long-shaft satin weave fabric woven with coarse warp yarns and fine weft yarns. Its characteristic is high strength primarily in the warp direction (0°).

- There is also Glass Fiber Unidirectional Weft Fabric, available in both warp-knitted and woven types. It is characterized by coarse weft yarns and fine warp yarns, with the glass fiber yarns mainly oriented in the weft direction, providing high strength in the we weft direction (90°).

4.Glass Fiber 3D Fabric (Stereoscopic Fabric) 3D fabrics are relative to planar fabrics. Their structural features have evolved from one-dimensional and two-dimensional to three-dimensional, giving the composite materials reinforced by them good integrity and conformability, significantly improving the interlaminar shear strength and anti-damage tolerance of the composites. They were developed to meet the special needs of the aerospace, aviation, weaponry, and marine sectors, and their application has now expanded to include automotive, sporting goods, and medical equipment. There are five main categories: woven 3D fabrics, knitted 3D fabrics, orthogonal and non-orthogonal non-crimp 3D fabrics, 3D braided fabrics, and other forms of 3D fabrics. The shapes of 3D fabrics include block, columnar, tubular, hollow truncated cone, and variable-thickness irregular cross-sections.

5.Glass Fiber Preform Fabric (Shaped Fabric) The shape of preform fabrics is very similar to the shape of the product they are intended to reinforce, and they must be woven on dedicated looms. Symmetrical shaped fabrics include: spherical caps, cones, hats, dumbbell-shaped fabrics, etc. Asymmetrical shapes like boxes and boat hulls can also be produced.

6.Glass Fiber Core Fabric (Through-Thickness Stitching Fabric) Core fabric consists of two parallel layers of fabric connected by longitudinal vertical strips. Its cross-sectional shape can be triangular, rectangular, or honeycomb.

7.Glass Fiber Stitch-Bonded Fabric (Knitted Mat or Woven Mat) It is different from ordinary fabrics and from the usual sense of mat. The most typical stitch-bonded fabric is formed by overlaying one layer of warp yarn and one layer of weft yarn, and then stitching them together to form a fabric. Advantages of stitch-bonded fabrics include:

- It can increase the ultimate tensile strength, anti-delamination strength under tension, and flexural strength of FRP laminates.

- It reduces the weight of FRP products.

- The flat surface makes the FRP surface smoother.

- It simplifies hand lay-up operation and improves labor productivity. This reinforcing material can replace CFM in pultruded FRP and RTM, and can also replace woven roving in centrifugal cast FRP pipe production.

Post time: Oct-22-2025