In the field of new energy vehicle batteries, aerogel is driving revolutionary improvements in battery safety, energy density, and lifespan due to its properties of “nano-level thermal insulation, ultra-lightweight, high flame retardancy, and extreme environment resistance.”

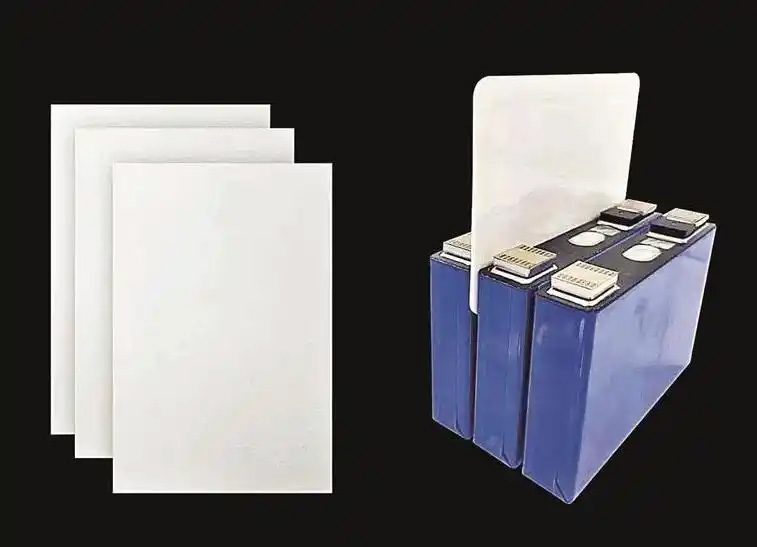

After prolonged power output, the sustained chemical reactions within vehicle batteries cause significant heating, posing risks of combustion or explosion. Traditional core modules use plastic separators to isolate cells, which serve no practical purpose. Not only are they heavy and ineffective at protection, but they also risk melting and igniting when battery temperatures become excessively high. Existing protective felt structures are simple and prone to deformation, preventing full contact with the battery pack. They also fail to provide adequate thermal insulation during severe overheating. The emergence of aerogel composite materials holds promise for addressing this critical issue.

Frequent fire incidents in new energy vehicles primarily stem from inadequate battery thermal insulation. Aerogel’s thermal insulation and flame-retardant properties play a significant role in new energy vehicle batteries. Aerogel can be used as a thermal insulation layer within battery modules, effectively reducing heat conduction and dissipation to prevent safety hazards like battery overheating and explosions. It also serves as thermal insulation and shock absorption between battery modules and casings, as well as external cold-proofing and high-temperature insulation layers for battery boxes. Its soft, easily-cut properties make it suitable for thermal protection between irregularly shaped battery modules and boxes, thereby enhancing battery efficiency and reducing energy consumption.

Specific application scenarios of aerogel in new energy vehicle batteries:

1. Battery thermal management: Aerogel’s high thermal insulation properties effectively reduce heat transfer during battery pack charging and discharging, improving thermal stability, preventing thermal runaway, extending battery life, and enhancing safety.

2. Insulation protection: Its excellent insulation properties provide additional safety for internal battery circuits, reducing fire risks caused by short circuits.

3. Lightweight Design: Aerogel’s ultra-lightweight properties help reduce overall battery weight, thereby improving the energy efficiency ratio and driving range of new energy vehicles.

4. Enhanced Environmental Adaptability: Aerogel maintains stable performance in extreme temperature conditions, enabling batteries to function reliably in cold or hot regions and expanding the application scope of new energy vehicles.

Within the new energy vehicle industry, aerogel insulation materials not only address battery system safety concerns but also leverage their flame-retardant properties for automotive interior applications. Aerogel materials can be integrated into vehicle structures such as roofs, door frames, and hoods, delivering cabin thermal insulation and energy-saving benefits.

The application of aerogel in new energy vehicle batteries not only enhances battery safety and performance but also provides critical safeguards for the overall safety and reliability of new energy vehicles.

Post time: Oct-31-2025