3/6/10mm glass fiber GFRC fiberglass strands blades for concrete cement

Product Description

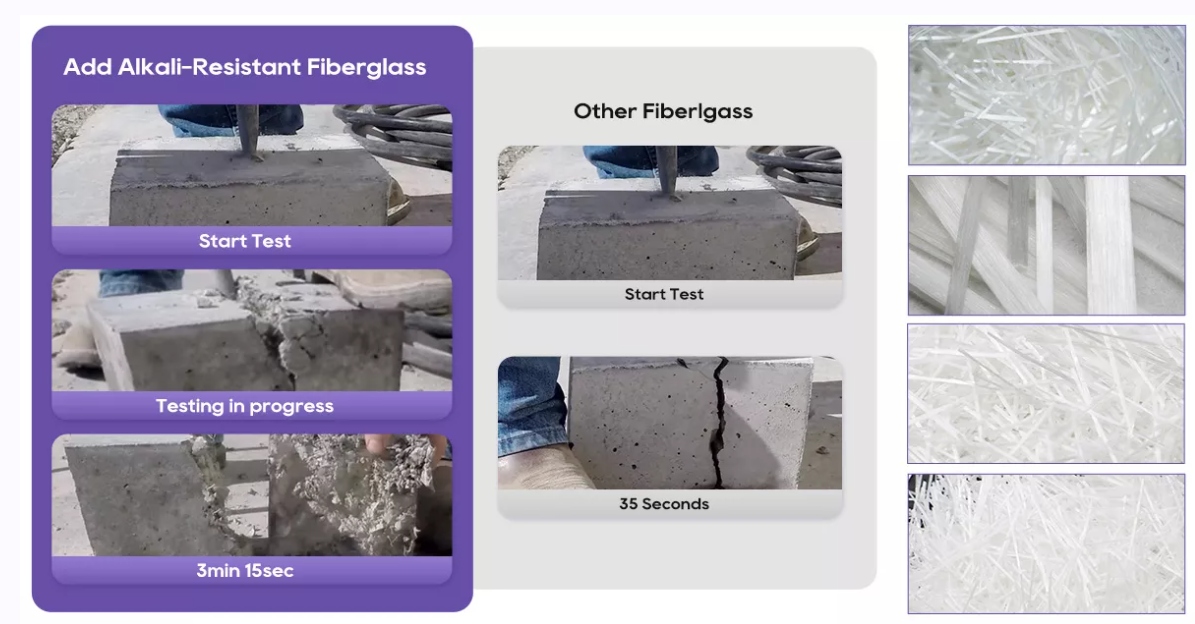

Alkali Resistant Glass fibres add strength and flexibility to the concrete resulting in a strong yet light-weight end product. The alkali resistance of Glassfibre depends principally on the content of Zirconia (ZrO2) in the glass.

Product List:

|

Product name |

|

|

Diameter |

15μm |

|

Chopped length |

6/8/12/16/18/20/24mm etc |

|

Color |

white |

|

Choppability(%) |

≥99 |

|

Usage |

Used in Concrete, Construction Work, Cement |

Benefits:

1. The AR glass is itself alkali resistant, It does not depend on any coating

2. Fine individual filaments: a very large number of fibers are released when mixed in the concrete and the filament does not protrude from the surface and be invisible when the concrete surface weathers.

3. Have a high tensile strength to withstand stresses during shrinkage.

4. Have a high modulus of elasticity to absorb shrinkage stresses before the concrete cracks.

5. Have a superior bond(mineral/mineral interface) with the concrete.

6. Present no health hazards.

7. AR glass fibers reinforce both plastic and hardened concrete.

Why use AR Glassfibre?

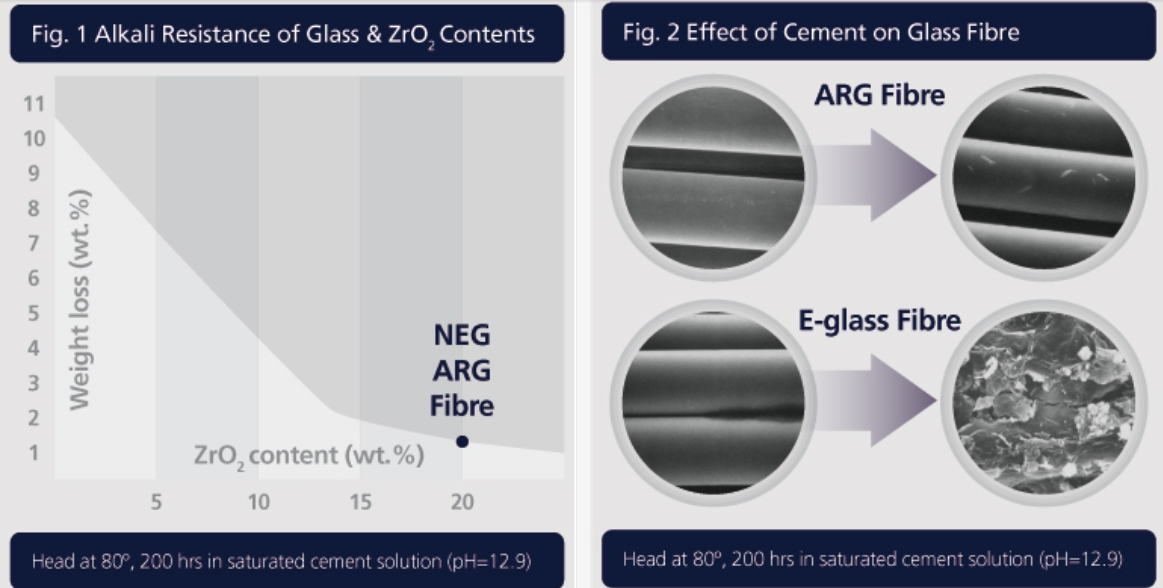

AR Glassfibre is essential for GRC because of its resistance to the high alkalinity levels in cement. The fibres add strength and flexibility to the concrete resulting in a strong yet light-weight end product. The alkali resistance of Glassfibre depends principally on the content of Zirconia (ZrO2) in the glass. The AR Glass fibre supplied by Fibre Technologies has a minimum zirconia content of 17%, the highest of any commercially available glass fibre.

Why is Zirconia Content Important?

Zirconia is what confers alkali resistance in glass. The higher the zirconia content the better the resistance to alkali attack. AR glassfibre also has excellent acid resistance.

Figure 1 shows the relationship between Zirconia content and the alkali resistance of glassfibres.

Figure 2 illustrates the difference between High Zirconia Alkali Resistant Glassfibres and E-glassfibre when tested in cement.

When purchasing Glassfibre for GRC manufacture or for use with other cementitious systems, always insist on certification showing the Zirconia content.

End use:

Mainly used in building , electronic , cars and mat raw material.

In building, length vary from 3mm to 30cm,diameter usually 9-13micron. AR Chopped Strands is suitable for stable buildings, earthquake proof, anti-crack.

In electronic , It’s performance mix with VE, EP, PA ,PP, PET, PBT to achieve. Such as electrical switch box, the composite cable bracket.

In cars, typical example is cars brake pads.Length usually 3mm-6mm,diameter is about 7-13micron.

In felt, chopped strand mat of the length is about 5cm,diameter is 13-17 micron. Needled felt of the length is about 7cm, diameter is 7-9 micron,starch coating.