2021 Good Quality Smc Roving - E-glass Assembled Roving For Filament Winding – Beihai Fiberglass

2021 Good Quality Smc Roving - E-glass Assembled Roving For Filament Winding – Beihai Fiberglass Detail:

E-glass Assembled Roving For Filament Winding

Assembled Roving for Filament Winding is specially designed for FRP filament winding process, compatible with unsaturated polyester.

Its final composite product delivers excellent mechanical property.

Features

●Excellent mechanical property

●Fast wet out in resins

●Low fuzz

Application

It is mainly used to manufacture storage vessels and pipes in petroleum, chemical and mining industries.

Product List

|

Item |

Linear Density |

Resin Compatibility |

Features |

End Use |

|

BHFW-01A |

2400, 4800 |

UP |

fast wet out, low fuzz, high strength |

pipeline |

| Identification | |

| Type of Glass |

E |

| Assembled Roving |

R |

| Filament Diameter, μm |

13 |

| Linear Density, tex |

2400, 4800 |

| Technical Parameters | |||

|

Linear Density (%) |

Moisture Content (%) |

Size Content (%) |

Breakage Strength (N/tex) |

|

ISO 1889 |

ISO 3344 |

ISO 1887 |

ISO 3341 |

|

±6 |

≤0.10 |

0.55±0.15 |

≥0.40 |

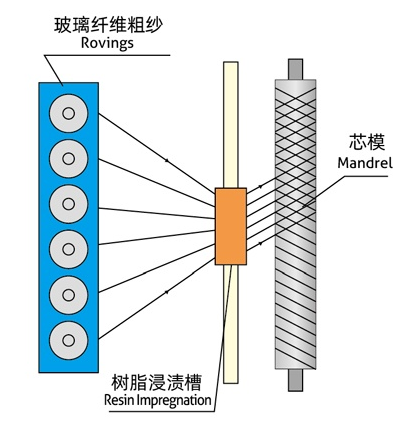

Filament Winding Process

Traditional Filament Winding

In the filament winding process , continuous strands of resin-impregnated glassfiber are wound under tension onto a mandrel in precise geometric patterns tobuild up the part which is then cured to form the finished parts.

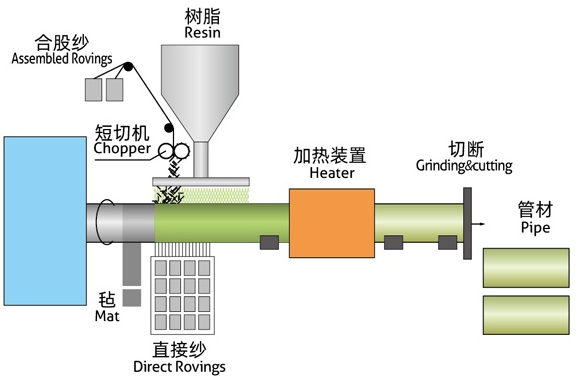

Continuous Filament Winding

Multiple laminate layers , composed of resin , reinforcement glass and other materials are applied to a rotating mandrel , which is formed from a continuous steel band continuously traveling in a cork-screw motion . The composite part is heated and cured in place as the mandrel travels through the line and then cut into a specific length with a traveling cut-off saw .

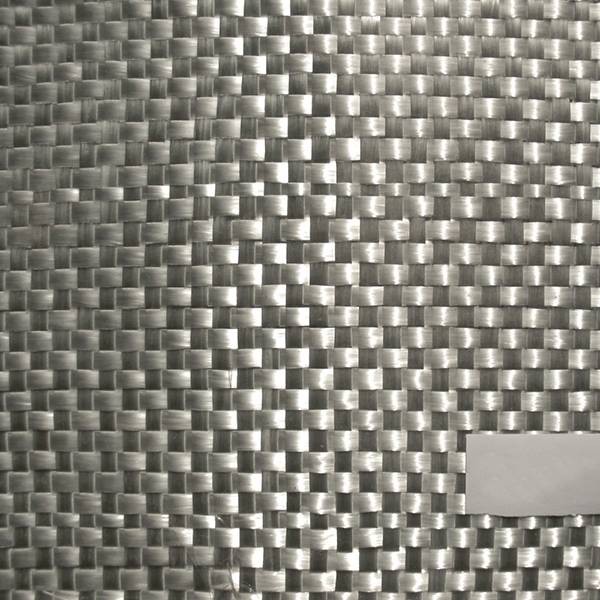

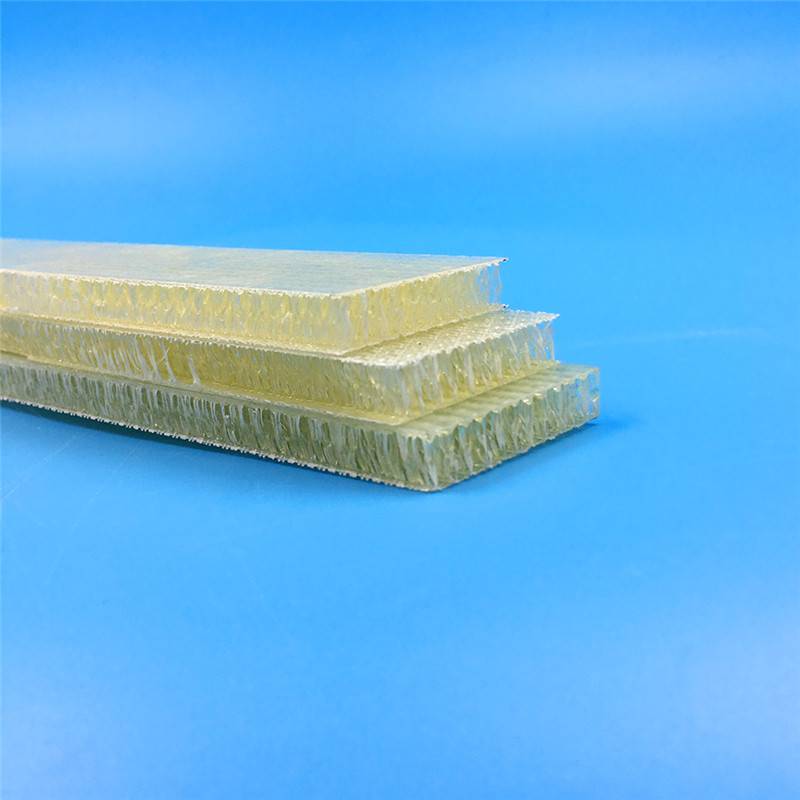

Product detail pictures:

Related Product Guide:

Being supported by an state-of-the-art and skilled IT team, we could supply technical support on pre-sales & after-sales service for 2021 Good Quality Smc Roving - E-glass Assembled Roving For Filament Winding – Beihai Fiberglass , The product will supply to all over the world, such as: Canada, Angola, Eindhoven, To meet the requirements of individual customers for each bit more perfect service and stable quality products. We warmly welcome customers around the world to visit us, with our multi-faceted cooperation, and jointly develop new markets, create a brilliant future!

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!