2021 Good Quality Glass Fiber Emulsion Chopped Strand Mat - Fiberglass Chopped Strand Mat Powder binder – Beihai Fiberglass

2021 Good Quality Glass Fiber Emulsion Chopped Strand Mat - Fiberglass Chopped Strand Mat Powder binder – Beihai Fiberglass Detail:

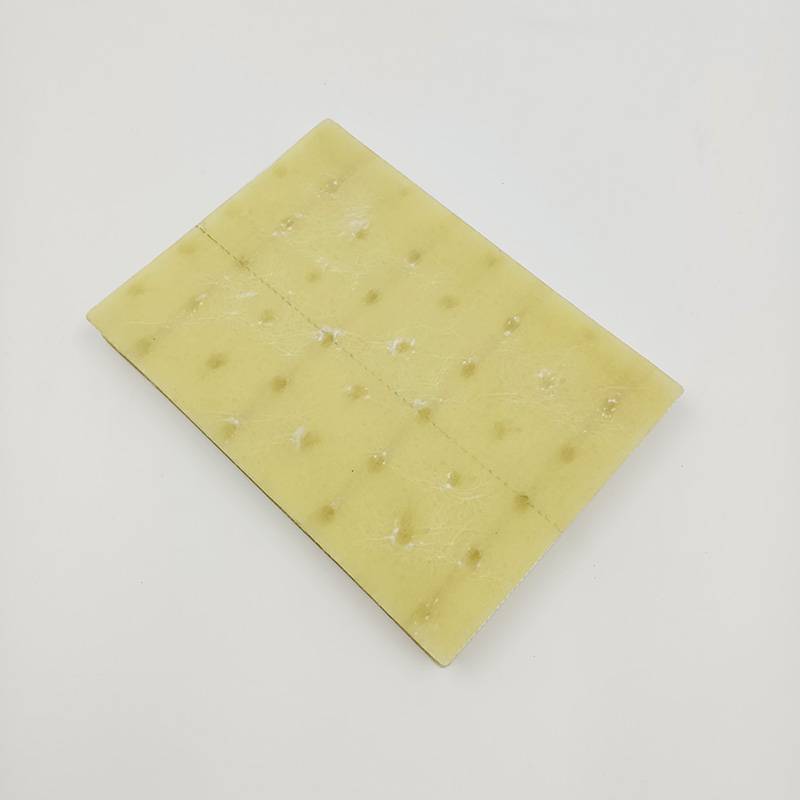

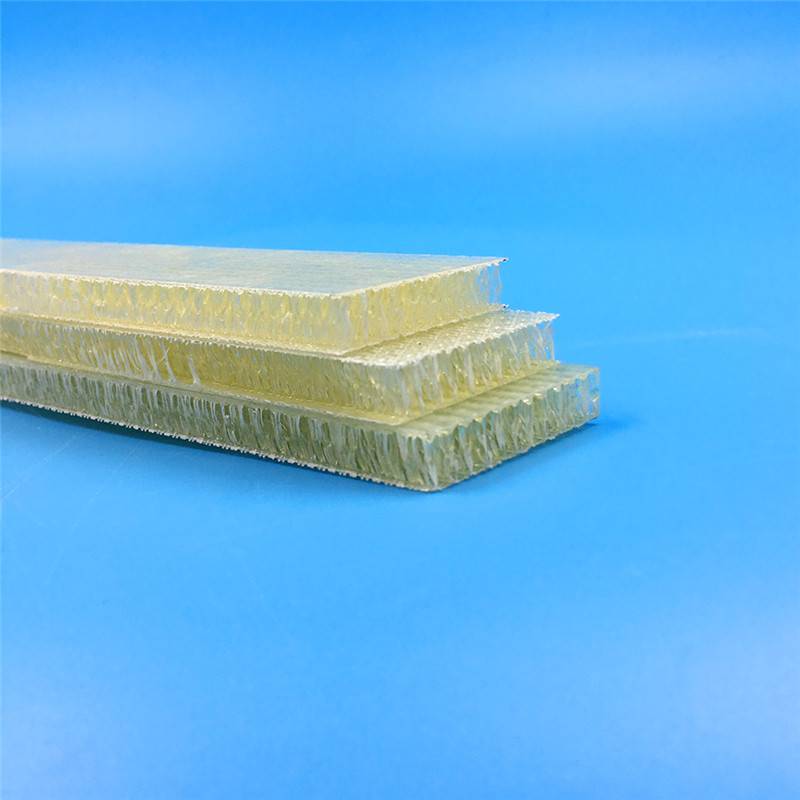

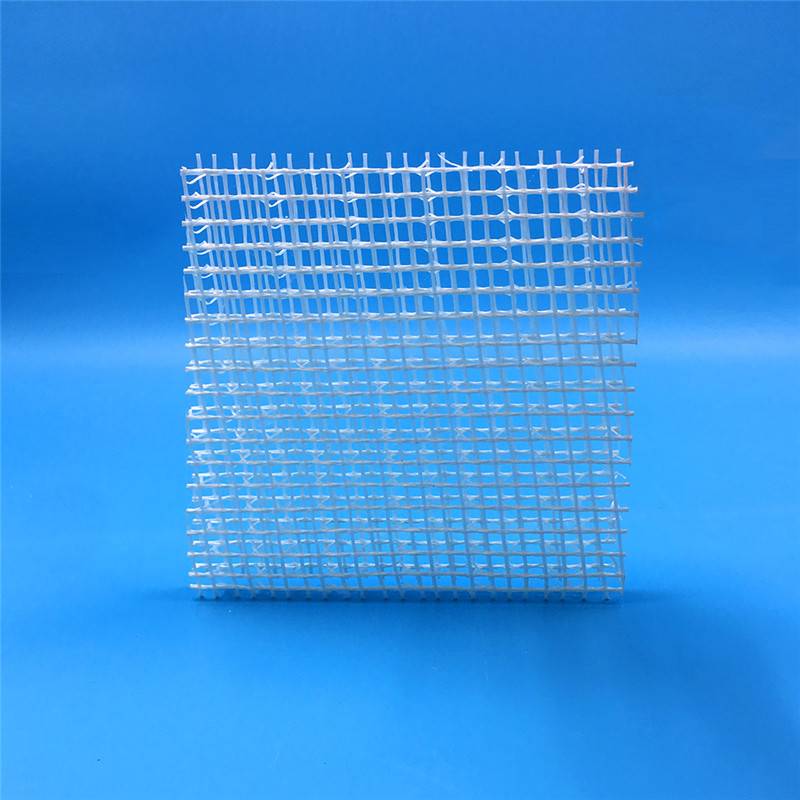

E-Glass Powder Chopped Strand Mat is made of randomly distributed chopped strands held together by a powder binder.It is compatible with UP, VE, EP, PF resins.The roll width ranges from 50mm to 3300mm.

Product Features

● Fast breakdown in styrene

● High tensile strength, allowing for use in hand lay-up process to produce large-area parts

● Good wet-through and fast wet-out in resins, rapid air lease

● Superior acid corrosion resistance

Application

Its end-use applications include boats, bath equipment, automotive parts, chemical corrosion resistant pipes, tanks, cooling towers and building components

Additional demands on wet-out and decomposition time may be available upon request. It is designed for use in hand lay-up, filament winding, compression molding and continuous laminating processes.

Product Specifications

|

Property |

Area Weight |

Moisture Content |

Size Content |

Breakage Strength |

Width |

|

(%) |

(%) |

(%) |

(N) |

(mm) |

|

|

Property |

IS03374 |

ISO3344 |

ISO1887 |

ISO3342 |

50-3300 |

|

EMC80P |

±7.5 |

≤0.20 |

8-12 |

≥40 |

|

|

EMC100P |

≥40 |

||||

|

EMC120P |

≥50 |

||||

|

EMC150P |

4-8 |

≥50 |

|||

|

EMC180P |

≥60 |

||||

|

EMC200P |

≥60 |

||||

|

EMC225P |

≥60 |

||||

|

EMC300P |

3-4 |

≥90 |

|||

|

EMC450P |

≥120 |

||||

|

EMC600P |

≥150 |

||||

|

EMC900P |

≥200 |

Special specification can be produce according to customer requirements.

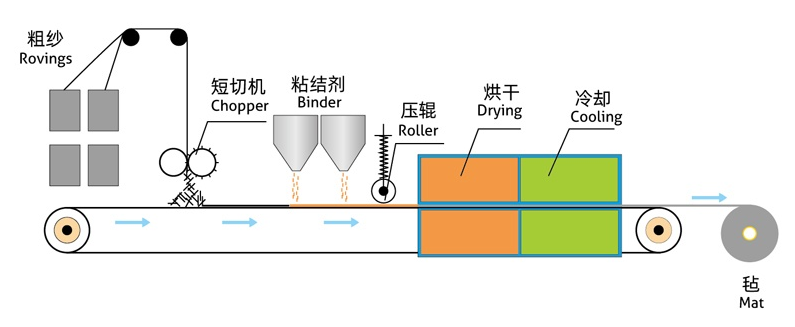

Mat Production Process

Assembled rovings are chopped to a specified length, and then fall onto a conveyor randomly.

The chopped strands are bonded together by either an emulsion binder or a powder binder.

After drying, cooling and winding, a chopped stand mat is formed.

Packaging

Each Chopped Strand Mat is wound onto a paper tube which has an inside diameter of 76mm and the mat roll has a diameter of 275mm. The mat roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be vertically or horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Storage

Unless otherwise specified, Chopped Strand Mat should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

Product detail pictures:

Related Product Guide:

We normally believe that one's character decides products' quality, the details decides products' high-quality ,while using the REALISTIC,EFFICIENT AND INNOVATIVE staff spirit for 2021 Good Quality Glass Fiber Emulsion Chopped Strand Mat - Fiberglass Chopped Strand Mat Powder binder – Beihai Fiberglass , The product will supply to all over the world, such as: United Arab emirates, Croatia, Berlin, Our company has a skillful sales team, strong economic foundation, great technical force, advanced equipment, complete testing means, and excellent after-sales services. Our products have beautiful appearance, fine workmanship and superior quality and win the unanimous approvals of the customers all over the world.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.