These days, with the economy growing and our lifestyles getting better, hitting the gym or working out has become a go-to way for folks to de-stress and stay healthy. That’s really pushing the sports gear industry forward, too. Now, whether it’s pro sports or just staying active, everyone wants equipment that’s top-notch—super light, tough as nails, and built to last. That’s where carbon fiber fabric comes in. It’s crazy light but super strong, stiff, and doesn’t wear out easily. No wonder it’s showing up in all kinds of sports gear, making them way better to use.

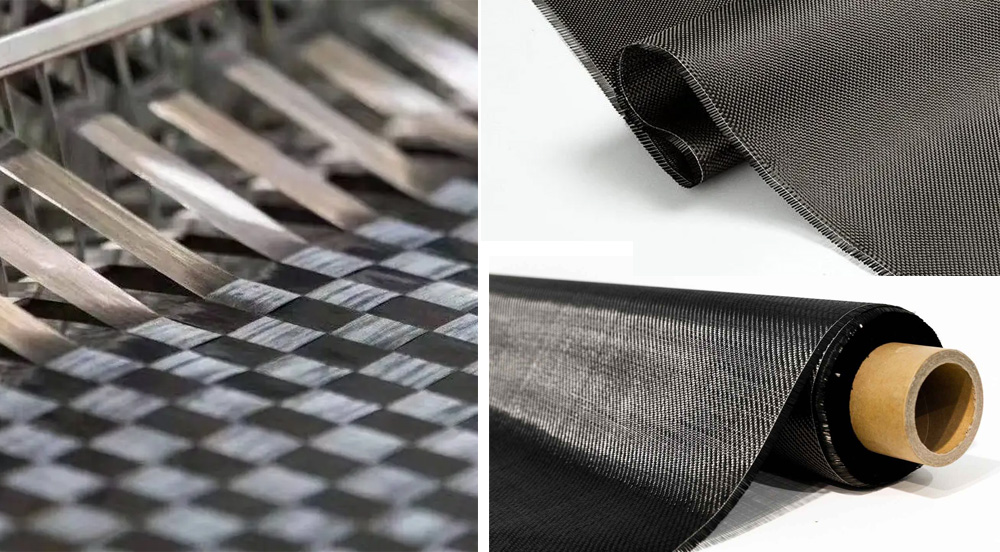

Carbon Fiber Fabric Structure and Material Overview: Carbon fiber fabric is a special textile composed of warp and weft yarns, with carbon fibers serving as the reinforcing element. Its core performance mainly stems from the outstanding characteristics of carbon fibers themselves. Carbon fiber is a high-performance material with a carbon content exceeding 90%. It is produced by carbonizing the organic fiber precursor filament bundles at high temperatures. Its mechanical properties are excellent: the density is less than a quarter of that of steel, and the tensile strength exceeds 3500 megapascals. In addition, it possesses excellent heat resistance, corrosion resistance, anti-fatigue properties, low thermal expansion coefficient, and excellent electrical/thermal conductivity. Compared to aramid fibers and glass fibers, carbon fiber maintains good processability while demonstrating significant anisotropy.

Application Advantages of Carbon Fibre Cloth

1.Tennis rackets and tennis balls first appeared in Birmingham, England in the 19th century. By the middle of the 20th century, they had undergone extensive development and had become a global sport. With the popularization and widespread adoption of tennis, the lightweighting of tennis rackets became increasingly important. By the 1970s, American companies had incorporated carbon fiber into the structure of tennis rackets. Currently, many mid-to-high-end tennis rackets use carbon fiber fabric. Its advantages over other materials are obvious. The low-density carbon fiber fabric makes the racket design lighter and larger; its high strength and modulus characteristics enable it to withstand significantly greater string tension, typically 20% to 40% higher. Most importantly, the special vibration-damping properties of carbon fiber fabric reduce the racket’s vibration, providing players with better comfort.

2. Bicycles, with the rapid development of social economy, have surpassed merely being a means of transportation and have become an indispensable tool for fitness, exercise and competition in daily life. This transformation provides opportunities for improving the performance of bicycles. Usually, carbon fiber fabric can be applied to four key bicycle components: frame, front fork, crankset and seat post. Carbon fiber fabric is renowned for its light weight, high strength and excellent ductility, which can reduce the overall weight of the bicycle and enable riders to better control it. At the same time, carbon fiber fabric gives bicycles superior rigidity and vibration-damping performance.

After all Under the backdrop of national fitness policies and the upgrading of sports consumption, carbon fiber fabrics, with their comprehensive performance advantages, have become the key materials for achieving lightweight and high-performance sports equipment. With the continuous advancement of manufacturing processes and the gradual optimization of costs, the application of carbon fiber fabrics in the sports field will further expand, driving the development of sports equipment towards a lighter, stronger, and more intelligent direction.

Post time: Jan-09-2026